October 27, 2014 weblog

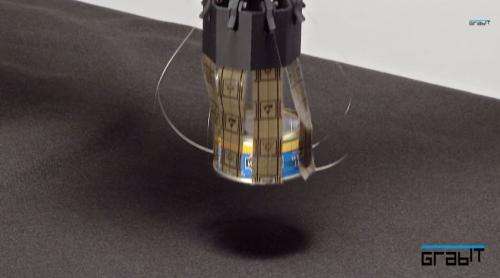

Grabit uses electroadhesion for good grip on objects

Grabit is a company that focuses on the use of electroadhesion for robotic pickup; they may have the key for better times in manufacturing, showing through videos how their product can improve productivity in manufacturing and logistics sectors. Electroadhesion is a technology that applies to robotic parts handling, parts fixturing, warehouse logistics and conveying systems. Their technology is out to demonstrate that reliable grasping can occur with no need for part-specific grippers and no need for bulky, energy-intensive vacuum technology or mechanical grippers. There is also no need for vacuum hoses and pumps. The technology signifies energy savings. Grabit products operate at very low energy levels and these are also quiet operations. A thin, LED backlight, integrated in the gripper, provides uniform lighting for vision inspection and vision-guided part registration.

The significance of all this, said MIT Technology Review, is that a novel gripper has come on the scene which could enable robots to take on new tasks. This would expand what machines can accomplish in efficient picking. Fundamentally, as Kevin Bullis described it, we are talking about a robotic hand that makes use of electrostatic attraction. "It uses powered electrodes to sustain the electrostatic attraction, and alternating polarities to avoid charge buildup and keep the device from collecting dust," he said.

The flexible surface of the grabber lets it support more weight and distribute the gripping force more evenly than can conventional robots that use suction, said Bullis. Anything can be grabbed—-phones, fabric, a bag of crisps, big boxes of paper, single sheets of paper. Electroadhesion enables a flexible, general-purpose platform technology that can successfully handle objects, shapes, sizes and materials. Also, electroadhesion can be applied to materials with smooth, rough, or dusty surfaces. The flexible electrostatic adhesion grippers provide even force on a surface, and eliminate scratches and smudges from delicate surfaces. Beyond industrial automation, electroadhesion can address biomedical, military, and consumer needs. Last year, cofounder and CEO Charlie Duncheon noted that electrostatic force was not something new, but the company's breakthrough was "doing it in a compliant manner with low-cost materials. Finely machined ceramics are very expensive, and hard to scale for large surface areas. We scale up at much lower cost."

California-based Grabit is an SRI International spinoff company. The electroadhesion technology was invented and patented within the Robotics Program at SRI. Grabit is not alone in pursuing opportunities to make a difference in factory automation. Technologists elsewhere are trying to improve on grippers that are agile, safe and precise. As Dante D'Orazio, reporter for The Verge, pointed out on Sunday, "Grippers are the business end of robots: without them, machines wouldn't be able to pick up or manipulate objects. But it's not easy to pick things up: many robots rely on mechanical movements or vacuum suction, both of which are big, expensive, and power hungry."

Grabit said it currently has more than a dozen customers globally, including several Fortune 500 companies in industries such as warehouse automation, parcel handling, consumer products, and textiles. They offer grippers and fixtures, case and box-handling grippers, and smart conveyors for manufacturing and logistics.

More information: — www.grabitinc.com/

© 2014 Tech Xplore