May 16, 2015 weblog

Polysis is marketing a plastic that turns to clay

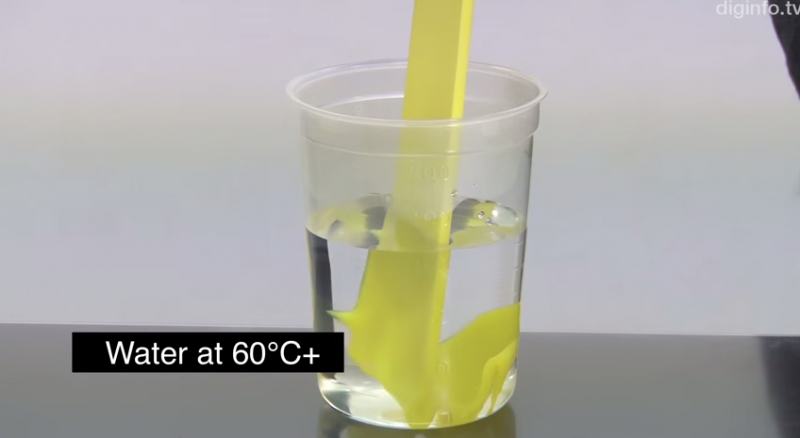

Polysis is showing a plastic that can turn to clay when heated, according to a story on DigInfo TV. Polysis is described as a specialist developer of polyurethane resins and resin products, and they are marketing haplafreely, presented with a lower-case "h," as a plastic that turns to clay when heated to temperatures above 60 degrees Centigrade.

Immerse the product in hot water—or heat it with a heat gun—and you find that the plastic is easy to shape, yet hardens again as it cools—and returns to its original hardness by the time it reaches room temperature.

Takato Mori, development division of Polysis, said the product remains in its clay state—staying malleable— five to 10 times longer than other products."It also has a tensile strength," he said, "three times greater than ordinary rubber, making it hard to break."

It's not difficult to peel off haplafreely; it won't stick easily to other materials, according to DigInfo TV. It is softer than other plastics. As a cover material, it will not damage the product to which it is applied.

Promoted benefits include cutting costs. One does not have to think about thermal design or processing; the product can be formed into different shapes without them. "When heated, it will return to clay time and time again, making it ideal as a way of reducing costs in production line jigs."

Real-world uses? The presentation suggested haplafreely as a cover for various components. Mori said haplafreely can be used to form bases on which to place unstable objects. For example, engine components need to be placed on a base for stability. Another case, he said, might be where motorcycle handlebars need to be worked on with a screwdriver. Haplafreey can be used in large quantities for protective covering.

Polysis is currently selling haplafreely in sheets measuring 40cm x 40cm and 4mm in thickness, and is aiming for monthly sales of 1,000 sheets, but haplafreely is also available in roll form, in thicknesses ranging from 0.6mm to 1.0mm.

The DigInfo TV report stated that "Polysis has received many requests from users for products that become soft at 70, 80 or 100°C, and will begin developing these this year."

Commenting, Lee Mathews in Geek.com said the product was "noteworthy for its ability to become malleable with a minimal amount of heat applied." He said haplafreely could make a difference on production lines. "If parts can be molded at a lower temperature, that means reduced energy use and shorter production times, which ultimately turns into either savings for you and me or higher profit margins for the producer. Or maybe even both."

© 2015 Tech Xplore