Scientists manufacture a difunctional composite for high-performance Li-S batteries

Researchers at South China Normal University and Soochow University have reported a new difunctional Li-S battery separator (CC-rGO/AB/PP) derived from a novel synthesis method under extreme pressure (1 Pa, -50 C) to promote more efficient Li-S batteries in a simple way.

The increasing demand for energy storage, especially for electric vehicles and power stations, calls for higher-energy storage batteries. Lithium-sulfur (Li-S) batteries theoretically have energy capacity far beyond lithium-ion batteries and have thus attracted much attention.

However, the actual lifespan and conversion efficiency are significantly reduced by the shuttle effect in which lithium polysulfides (LiPSs) dissolve and penetrate to the anode during discharge and cause internal short-circuit. Although there are techniques to suppress the shuttle effect by the separator, most of them still have to sacrifice other performance indicators, such as the ability of lithium-ion transportation.

Publishing in the journal International Journal of Extreme Manufacturing, the team led by Professor Weishan Li and Youyong Li manufactured and investigated the laminar N,O-carboxymethyl chitosan-reduced graphene oxide/acetylene black/polypropylene (CC-rGO/AB/PP) separator.

Reduced graphene oxide (rGO) is a popular material used to improve the performance of lithium-sulfur (Li-S) batteries, but its traditional synthesis method usually involves high temperatures and complicated chemical processes. Additionally, the folded and compact multilayer structure of rGO is not beneficial for lithium-ion transportation due to the small surface area.

Studies show that the rGO can be obtained by the reduction induced by reducing groups, and separated into monolayers by inserting macromolecules. It is worth noting that the reaction promotes automatic assembly of external "chemical parts" onto the material surface, also known as self-assembly. Meanwhile, the heteroatoms in materials are crucial to improve battery performance, since they can provide active sites that have double functions, i.e., repelling LiPSs and transferring Li+.

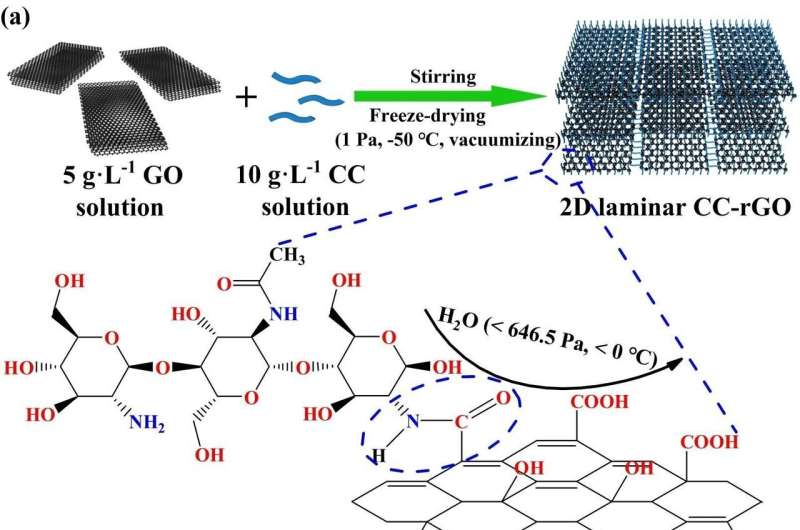

To make full use of all these characteristics, self-assembly and freeze-drying technologies were merged into a novel method for synthesizing chemically modified rGO monolayers, which also ensures ynthetic efficiency since the extreme freeze-drying condition accelerates both the reductive reaction of GO and the heteroatom modification. The synthesis excludes toxic organic solvents mentioned in similar works, and uses eco-friendly N,O-carboxymethyl chitosan (CC) to provide reducing groups and heteroatoms for graphene oxide (GO).

Subsequently, the CC-rGO was mixed with acetylene black (AB), and the mixture was coated on the polypropylene (PP) membrane to manufacture the separator CC-rGO/AB/PP. As a result, the Li-S battery using the new separator not only completely suppresses LiPSs but also exhibits considerable Li+ transportation, which enables it to compete with or even surpass the previous best achievements in this field. This could not only provide an environmentally friendly GO reduction method, but also present new ideas to design and commercially produce novel separators for high-performance Li-S batteries.

Professor Weishan Li, leader of the South China Normal University research group, said, "To suppress the shuttle effect of lithium polysulfide (LiPSs), many strategies have been proposed. The early strategy is to develop hosts for sulfur, which can physically adsorb LiPSs, such as carbon tubes, carbon spheres, and reduced graphene oxide, or chemically adsorb LiPSs, such as metal oxides, nitrides, and sulfides. Recently, using modified catalysts which exhibit strong affinity with LiPSs to accelerate the conversion kinetics between S8 and Li2S has also been widely focused on."

He pointed out, "To some extent, these efforts improve the performances of Li-S battery, but the dissolution of LiPSs cannot be completely avoided. As a response, modifying separators by coating with materials that can block the penetration of LiPSs, has been adopted to suppress the shuttle effect of LiPSs. These separators seem effective in blocking the penetration of LiPSs, but the introduction of other materials might also hinder the lithium-ion transportation."

"Our work is aimed to search for the coated materials that can satisfy both sides, i.e., not only suppresses LiPS penetration, but also favors the lithium-ion transportation for improving the Li-S battery," Professor Weishan Li said.

"Actually, the process of synthesizing reduced graphene oxide (rGO) from graphene oxide (GO) is converting oxygen-containing groups into free water. When we dropped alkaline aqueous solution, which may facilitate the conversion, into GO solution in an experiment, we found that GO self-assembled together too by accident. This accident inspired us to design the synthesis method of N,O-carboxymethyl chitosan-reduced graphene oxide (CC-rGO) under extreme conditions," first author Dr. Zhibin Jiang explained.

The research team is also interested in the microscopic mechanism of the outstanding performance of the novel separator, especially the contribution of CC-rGO. Dr. Jiang Zhibin said, "An instinctive idea is to compare the chemical binding in the separator at the fully discharged and charged state."

Unsurprisingly, the binding signals between LiPSs and heteroatoms and the stable structure signals of CC-rGO were uniquely detected at the fully discharged state in the experiment, which confirms the main contribution and stability of CC-rGO. Combined with the theoretical simulations provided by the group of Professor Youyong Li at Soochow University, the role of the heteroatoms as well as the interactions provided by CC-rGO for LiPSs that is obviously stronger than those of traditional materials were further illustrated.

Dr. Zhibing Jiang said, "This is an advancement that comprehensively considers the performance, cost, as well as greenness, and the manufactured laminar CC-rGO composite is promising to be applied in large scale for high-performance Li-S batteries."

More information: Zhibin Jiang et al, Manufacturing N,O-carboxymethyl chitosan-reduced graphene oxide under freeze-dying for performance improvement of Li-S battery, International Journal of Extreme Manufacturing (2022). DOI: 10.1088/2631-7990/aca44c