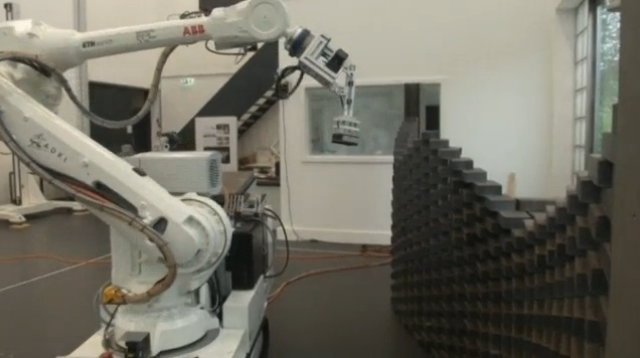

Robots engineered for construction sites are in the news this week. Namely, there is a robot called the In-situ Fabricator. Described as an autonomous construction robot, one can put the accent on autonomous.

The IF represents an important step in robotics designed for use in construction. They are in brief being designed to be smarter. They are more than factory-like machines that stand in one place and place objects in piles but are engineered to move around and adapt to changing situations.

A detailed report from Jim Drury in Reuters focused on what is on the minds of engineers at the Swiss National Center of Competence in Research (NCCR) Digital Fabrication. The center is located at the ETH Zurich >campus.

The NCCR director, Prof. Matthias Kohler, said it was the first machine that can actually go on construction sites and build nonstandard designs. He referred to designs that vary and adapt to local conditions in the building site.

Laying bricks in pre-programmed structures is not the central feature in its repertoire. Sensors and onboard computing help it build up a 3D site map. It has a 2D laser range finder which acts in conjunction with computer algorithms that construct the map.

Prof. Jonas Buchli, ETH Zurich, said two computers were on board, one for the arm and one for the overall robot. Computers calculate information for the robot to move and to know where it is. That translates into robots moving around the sites unaided. They can adapt on their own to minor design variations.

The robot can adapt to circumstances that were not planned—a dropped builder's tool, a later design change. Prof. Jonas Buchli, who supervises the research, told Reuters that roboticists in research find construction sites interesting environments, "somewhere in between the completely planned and controlled environment of a factory or a lab floor, and the completely chaotic environment of outdoors."

Buchli said it was the kind of semi-structured environment where researchers could test and develop the technology needed for robots to move around and do useful things in such environments.

Drury also reported on programs under way:

The engineers are training a focus on "robotic aggregations of materials with unpredictable geometry, in which random pieces of rubble can be measured by robot and structured to fit together to make a complete standing structure."

Then there is the Mesh Mould project. This looks at a digitally-controlled, 3D printed, extrusion process. In this one, "robotically fabricated reinforcement meshes can be filled with concrete, eliminating the need for formwork."

What about the usual worries that such machines will cost humans jobs? Kohler does not see the construction-site robotics advancements as harmfully either-or.

"I think this will become a game-changer in construction," he said in Reuters. He sees mobile robots on the construction site in the next five to ten years, but as actually collaborating with humans, "so the best of each kind of skills come together."

Still, that did not stop Bryan Lufkin in Gizmodo from asking: "I wonder if more robots on construction sites would lead to a sharp drop in hard hat sales?"

© 2015 Tech Xplore