People in many industries treat 3d printing as a key topic of interest both in techniques and printing materials for a number of reasons. ZDNet had an article earlier this year which examined reasons behind the interest.

Rapid prototyping would allow companies to experiment and try new products at cheaper costs than was possible Another opportunity that 3D printing could offer is the ability to produce small batches of high-quality goods, personalized according to the customers' requests, in a more cost-effective way than before.

The article said that in Mestre near Venice, shoemaker Simone Segalin used a 3D printer for a shoe to be created on-demand, tailored to a customer's foot. The client needed to measure her foot with a laser scanner and email the data to Venice, where the shoe was to be produced and shipped back.

New Balance made news this week as a well known shoe brand stepping up to 3D printing's future in footwear.

Tyler Koslow, a writer for 3D Printing Industry, said, "3D printing technology has been utilized for footwear and orthopedic support by quite a few companies and individuals thus far. From the medically-supportive company SOLS, who 3D print custom-made insoles for the comfort and support of each wearer, to the fashionable reactive footwear created by MIT designers, additive manufacturing is no stranger to our feet."

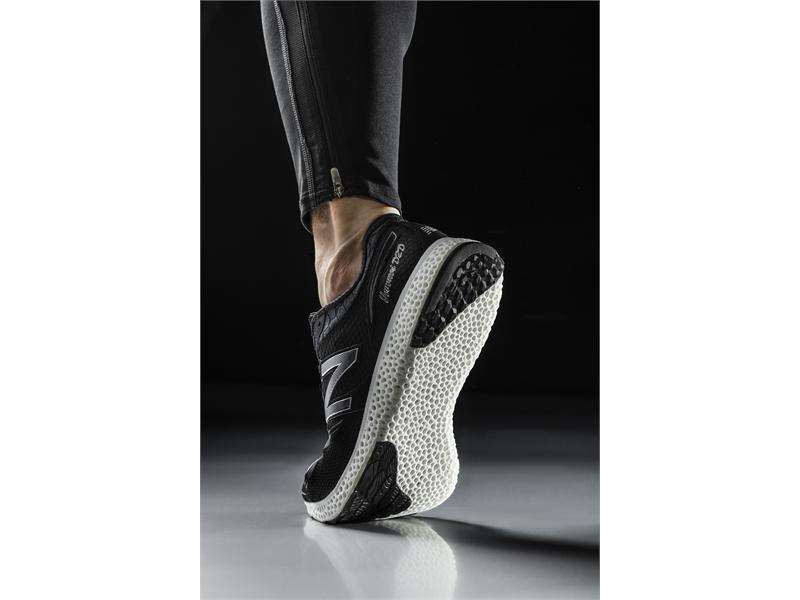

New Balance has made news with its 3D-printed running shoe. In 2016, New Balance will bring running shoes with 3D-printed midsoles out of the lab. The company announced Thursday they will launch the running shoe with its 3D-printed midsole.

This is a collaboration between the shoe company and 3D Systems. That collaboration opened doors for biomechanics experts to sit down with plastics engineering and design experts.

The company talked about the printing technique in having used selective laser sintering (SLS). This is a process which converts powder materials into solid cross-sections, layer by layer, using a laser. They used 3D Systems' elastomeric powder DuraForm Flex TPU. The latter gives parts a combination of strength and elasticity suitable for performance running shoes.

New Balance, said Fast Company, "says it has found a material that achieves an acceptable mix of flexibility and weight for performance wear. This year, New Balance partnered with South Carolina-based 3D Systems to incorporate one of the company's' new elastomer materials into its printing process."

Koslow said New Balance did not just hop on to the printing bandwagon overnight. "New Balance has been experimenting with implementing 3D printing technology into footwear design since 2012," he said. In 2013, according to the company, a track athlete, middle distance runner Jack Bolas, competed with data-customized, 3D-printed spike plates.

When will you see the running shoes in action? First as a limited edition, the shoe will be available in April and then "in select New Balance retail locations around the globe." said the company. The shoes will also be on display and in use by employees in the 3D Systems booth at the Consumer Electronics Show in January.

Would consumers really care about whether not their shoe pars were 3D printed?

3D Systems blogged why it is a big deal, of benefit to consumers. "First things first, what's a midsole and why is it important? The midsole is the portion of the shoe base that is sandwiched between the outsole (the portion that touches the ground) and the upper (the portion that touches your foot). In other words, the midsole is everything that provides cushioning and support to your foot."

The blog said that with 3D printing, one can optimize structures to put as much or as little material precisely where desired. "This means new and organic geometries are possible through the bottom-up process of building layer-by-layer. Taking advantage of these benefits, New Balance has achieved an anatomical breakthrough in the full range of desired midsole characteristics, from flexibility and strength, to weight and durability."

More information: newbalance.newsmarket.com/LATE … E0-AE3B-A857F8D2A445

© 2015 Tech Xplore