Thin films of a lead-free piezoelectric finally match the performance of the lead-bearing standard

An advance in fabrication technology has greatly improved the material quality and performance of thin films of a lead-free 'piezoelectric' material. This development by A*STAR researchers promises to unlock a lead-free alternative to the lead–zircon–titanate (PZT) standard.

Piezoelectrics are remarkable materials that deform on application of an electric field and, conversely, produce an electric current when compressed. They are used in many electronics applications, including as electromechanical actuators and as sensors for strain and acceleration. Thin films of piezoelectric materials are also being integrated into microelectromechanical systems (MEMS) circuits and devices.

For decades, PZT was the piezoelectric material of choice, since it offered the degree of deformation or sensitivity needed for practical applications. However, PZT contains 60 per cent lead—a toxic metal, which although once commonly used in electronics, has been banned.

An alternative material, which is based on a potassium–sodium–niobate composition and is known as KNN, is being used as a replacement for PZT in many bulk applications. Yet thin films of KNN are problematic because they are subject to a breakdown of composition control and the atomic ordering needed to produce the piezoelectric effect.

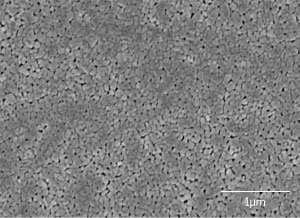

Now, Kui Yao and colleagues from the A*STAR Institute of Materials Research and Engineering, in collaboration with National University of Singapore researchers, have shown that a solution-based fabrication method using a painstakingly formulated cocktail of chemical agents can produce thin films of KNN with a piezoelectric performance comparable to PZT.

"It has been challenging to achieve excellent piezoelectric properties in KNN-based thin films because the phase conditions needed for the piezoelectric effect depend very sensitively on composition," explains Yao. "In KNN, it has been difficult to suppress the loss of volatile elements needed for these conditions."

Yao and his team overcame this problem by adding a blend of chemical stabilizing agents—refined over more than ten years of research—to the precursor solution used to prepare the KNN thin films. The interactions between the volatile alkali ions in solution and the stabilizing agent suppressed volatilization, allowing the compositions of the resulting films to be well controlled.

"With the film composition under control, we were able to study the phase transitions in the material and their dependence on the chemical composition and stress in the KNN-based thin films," says Yao.

Through laser measurements combined with theoretical analysis from first-principles simulations, the team confirmed that the performance of their piezoelectric films makes them a viable lead-free alternative to PZT.

More information: Yumei Wang et al. High Piezoelectric Performance and Phase Transition in Stressed Lead-Free (1 - x )(K, Na)(Sb, Nb)O3 -x (Bi, Na, K)ZrO3 Thin Films, Advanced Electronic Materials (2017). DOI: 10.1002/aelm.201700033