Gold 'micro jewels' from the 3-D printer

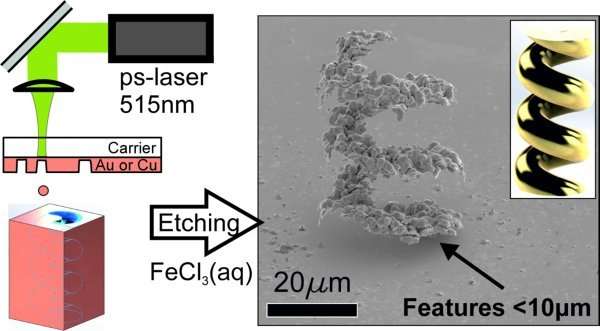

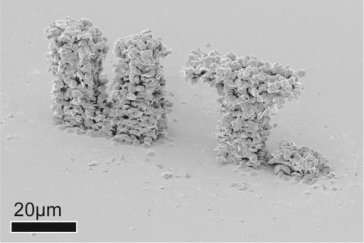

Thanks to a laser technique that ejects ultra-tiny droplets of metal, it is now possible to print 3-D metal structures—not only simple 'piles' of droplets, but complex overhanging structures, as well, like a helix measuring just microns in size, made of pure gold. Using this technique, it will be possible to print new 3-D micro components for electronics or photonics. University of Twente scientists publish their new results in Additive Manufacturing journal.

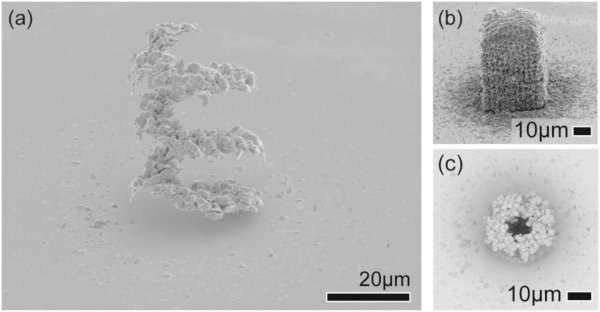

By shining an ultra-short laser pulse onto a nanometer-thin metal film, a tiny metal droplet melts and is ejected to its target, solidifying again after landing. Via this technique, called laser-induced forward transfer (LIFT), the UT researchers were able to build, drop by drop, a structure with copper and gold microdroplets. The copper acts as a mechanical support for the gold. In their paper in Additive Manufacturing, the researchers report printing a copper-gold helix. Such a structure could act as a mechanical spring or an electric inductor at the same time. This helix is printed with copper around it—together with the helix, a copper box is printed. In this way, subsequent droplets are prevented from landing on the previous winding. After building the helix, drop by drop and layer by layer, the copper support box is etched away chemically. What remains is a helix of pure gold, no more than a few tens of microns in size.

No mixing

The volume of the metal droplets is a few femtoliters—a femtoliter is 10-15 liters. To give an impression, a femtoliter droplet has a diameter of little over one micrometer. The droplets are made by lighting the metal using an ultrashort pulse of green laser light. In this way, the copper and gold structure is built. A crucial question for the researchers was whether the two metals would mix at their interface. This would have consequences for the quality of the product after etching. Research shows that there isn't any mixing. The way a structure is built, drop by drop, results in a surface roughness, which is only about 0.3 to 0.7 microns.

The LIFT technique is promising for other metals and combinations of metals, as well. The researchers expect opportunities for materials used in 3-D electronic circuits, micromechanic devices, sensors and biomedical applications. It is therefore a powerful new production technique on a very small scale, and an important step toward functionalisation of 3-D printing.

The paper "Printing of Complex Free-standing Microstructures via Laser-induced Forward Transfer (LIFT) of Pure Metal Films" will be published in the December print edition of Additive Manufacturing and is available now.

More information: Matthias Feinaeugle et al. Printing of complex free-standing microstructures via laser-induced forward transfer (LIFT) of pure metal thin films, Additive Manufacturing (2018). DOI: 10.1016/j.addma.2018.09.028

Provided by University of Twente