Researchers advance biomass transformation process

Biomass can serve as a renewable source for both energy and carbon. Acetone, n-butanol, and ethanol (ABE) fermentation broth as a biomass-derived source of fuels and chemicals has received a lot of attention for several decades. However, the crude fermentation broth contains low concentrations of oxygenates, limiting its practical applications.

Thus, it is important to develop a highly efficient water-resistant catalyst to directly and selectively convert crude aqueous oxygenate mixtures to value-added chemicals; water-immiscible ones (easy separation after reaction) are especially of great importance. However, the efficiency and selectivity of the transformation process for biomass-derived intermediates remains a major techno-economic challenge.

Prof. Wang Feng from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences and his colleagues from Peking University recently reported an efficient and novel catalytic method for the conversion of aqueous biomass fermentation broth to a water-immiscible product. Their finding was published in Nature Communications.

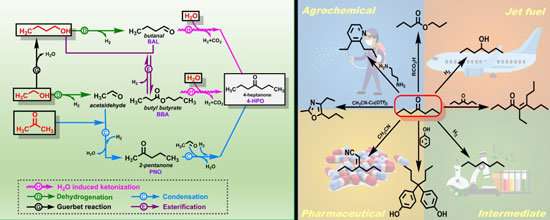

They developed a strategy capable of transforming ~70 percent of carbon in an aqueous ABE fermentation mixture to 4-heptanone (4-HPO), catalyzed by tin-doped ceria (Sn-ceria) with a selectivity as high as 86 percent. While Sn-ceria is a versatile catalyst for dehydrogenation, the Guerbet alcohol reaction, condensation, and esterification reactions, all these reactions, involving acid-base catalysis and redox ones, relay and generate 4-HPO with high selectivity (Fig. (A)). 4-HPO is a value-added intermediate and can be used to produce jet fuel and fine chemicals (Fig. (B)).

Furthermore, water, which is detrimental to the reported catalysts for ABE conversion, was beneficial for producing 4-HPO. The excellent catalytic performance of tin-doped ceria is due to the highly dispersed tin species and oxygen vacancies of ceria.

"This strategy offers a route for highly efficient organic carbon utilization," said Wang. "It can potentially integrate biological and chemical catalysis platforms for the robust and highly selective production of value-added chemicals."

More information: Yehong Wang et al, Selective production of phase-separable product from a mixture of biomass-derived aqueous oxygenates, Nature Communications (2018). DOI: 10.1038/s41467-018-07593-0

Journal information: Nature Communications

Provided by Chinese Academy of Sciences