In-ear silicon speakers for the internet of voice

"Hey Goosilexa, can I go swimming?" Today, we receive synthetically spoken answers to questions aimed at helping to make our decisions easier. Increasingly, voice-based services infiltrate everyday lives. Major hardware and content providers such as Apple, Google and Amazon have long been growing their businesses with powerful personal voice assistants.

In 2016, Bragi, a startup based in Munich, launched The Dash, the first so-called "hearable," sparking the evolution of the "Internet of Voice" with wireless earphones. Thanks to possible omnipresence in the ear, commodity services as well as personal assistance possibilities may soon become as commonplace as smartphones are today.

The idea of an Internet of Voice permanently worn in the ear is taking shape, paving the way for hearables to free themselves from accessory status as mere playback devices and move to claim the legacy of the smartphone. Privacy and data protection and reliable user identification are two factors key to ensuring acceptance. Requiring powerful edge computing for speech recognition, semantic processing and reading the "acoustic fingerprint" are necessary to support these factors.

Much like a personal firewall, users should ultimately set their own rules regulating which spoken content is released into the cloud and which is restricted to local use in the hearable. The energy requirements of the hearables are therefore determined by radio interfaces and audio processors. It is clear that energy-efficient components are needed to ensure the maximum desired runtime. Because the human ear naturally provides very limited space for a battery, components must operate at the lowest possible energy budgets.

Together with the Brandenburg Technical Universtiy Cottbus-Senftenberg (BTU), scientists at the Fraunhofer Institute for Photonic Microsystems (IPMS) located in Dresden and Cottbus have developed a new, power-efficient acoustic transducer principle for in-ear speakers. This central core component has now been presented in detail for the first time in Nature Microsystems and Nanoengineering .

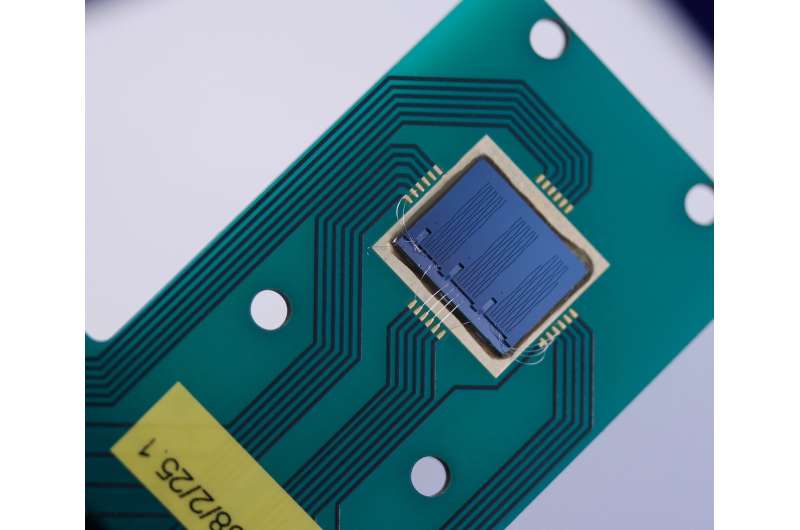

No longer using a conventional membrane, the new acoustic transducer principle takes consists of bending actuators similar to the strings of a harp placed within the volume of a silicon chip. New types of electrostatic bending Nano-e-Drive (NED) actuators have been integrated into the 20 µm-thin bending transducer. The voltage of the audio signal makes the actuators vibrate. To prevent any acoustic short circuit on either side, a team of scientists led by Bert Kaiser, Holger Conrad and Prof. Harald Schenk bonded two silicon wafer layers with input and output slots on the top and bottom of the bending actuator. Sound is therefore generated in microscopically small air chambers due to the movement of NED actuators within the silicon chip. The acoustic transducer principle allows for a complete silicon-based technology and enables the manufacturing of a micro-loudspeaker as microelectromechanical system (MEMS).

IPMS scientists and their BTU colleagues have proven the completely new transducer principle with measurements performed in the laboratory. Interestingly, the principle was used to demonstrate sound pressures over 100 dB on a small chip area. Simultaneously furthering miniaturization while increasing loudness and audio fidelity over a particularly large frequency range poses the next important challenge. The goal is to generate 120 dB from less than a 10 mm2 chip area. Combining the electrostatic converter principle with electronic amplifier circuits promise energy-efficient systems which, in addition to their use in in-ear headsets, are particularly suitable for use in hearables or even hearing aids. A 100 dB/mW sensitivity for the entire system was reported in the publication.

The silicon technology described in the publication is compatible with typical microelectronics manufacturing processes (CMOS compatibility) and does not use special materials such as lead-zirconium-titanate (PZT). In fact, the infrastructure for electronics integration, packaging and the mass production therefore already exists. Comparing today's situation with the state of MEMS-based microphones more than 10 years ago, commercial success with a high market penetration is to be expected for the new NED-based MEMS audio transducer approach. According to Prof. Harald Schenk, plans to found a new company for the marketing of the microspeaker are underway.

More information: Kaiser, B., Langa, S., Ehrig, L., Stolz, M., Schenk, H., Conrad, H., Schenk, H., Schimmanz, K., Schuffenhauer, D.: Concept and proof for an all-silicon MEMS micro speaker utilizing air chambers. Nature Microsystems & Nanoengineering, 2019. DOI: 10.1038/s41378-019-0095-9

Conrad, H., Schenk, H., Kaiser, B., Langa, S., Gaudet, M., Schimmanz, K., Stolz, M., Lenz, M.: A small-gap electrostatic micro-actuator for large deflections. Nature Communications 6, 10078, 2015. DOI: 10.1038/ncomms10078