A flaky option boosts organic solar cells

An inexpensive material, made from tungsten disulfide flakes just a few atoms thick, has helped to improve the performance of organic solar cells1. The discovery by KAUST researchers could be an important step toward bringing these photovoltaic cells into wider use for generating clean electricity.

Most solar cells use silicon to absorb light and convert its energy into electricity. But carbon-based semiconductor molecules, used in organic photovoltaics (OPVs), offer some distinct advantages over silicon. OPVs tend to be flexible, for example, which means they could be manufactured at a large scale using low-cost roll-to-roll printing. But the best OPVs convert about 16-17 percent of the light they capture into electrical power, well short of commercial silicon cells that exceed 20 percent.

Thomas D. Anthopoulos, and colleagues at the KAUST Solar Center, have estimated that OPVs could rival that performance if certain parts of the cell were improved2. When light hits the semiconductor, it frees electrons from the material and leaves positively charged holes. Electrons and holes are gathered up by different layers on opposite faces of the semiconductor and delivered to the cell's electrodes to generate a current. The leading hole transporter is a polymer called PEDOT:PSS, but it is acidic and absorbs moisture from the air, which degrades other materials in the solar cell.

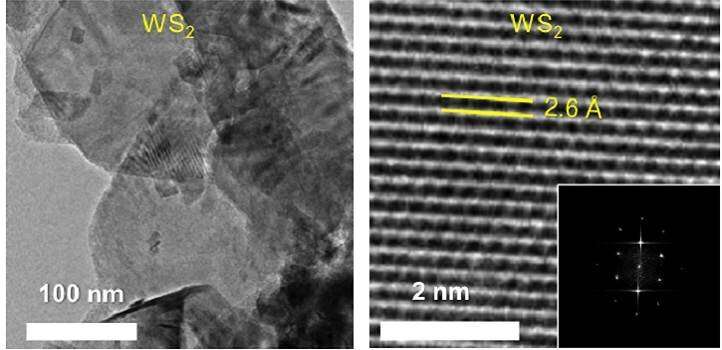

Anthopoulos's interdisciplinary team has now developed a hole-transporting layer made from flakes of a 2-D material, tungsten disulfide. The researchers used ultrasound to tear the flakes off powdered tungsten disulfide suspended in a mixture of water and ethanol. This sonication method is inexpensive and easy to scale up, and the flakes can be spread onto an electrode using a simple and widely used spin-coating process.

The team fabricated several OPVs this way, and the best had a power conversion efficiency of 17 percent, which is the highest for any OPV using a 2-D material as a hole transporter and among the highest for any OPV. "We were very surprised to reach 17 percent," says Yuanbao Lin, a Ph.D. student on the team. "We feel this is just the beginning and there is significant room for performance improvement."

The team found that the tungsten disulfide layer has a lower resistance than PEDOT:PSS and is also better at gathering holes than its rival, leading to improved performance. "Our immediate goal is to push the efficiency of our organic solar cells well beyond 17 percent and toward our theoretically predicted limits," says Anthopoulos. "We also aim to study the stability of these high-efficiency organic solar cells."

More information: Yuanbao Lin et al, 17% Efficient Organic Solar Cells Based on Liquid Exfoliated WS 2 as a Replacement for PEDOT:PSS, Advanced Materials (2019). DOI: 10.1002/adma.201902965 , dx.doi.org/10.1002/adma.201902965

Yuliar Firdaus et al. Key Parameters Requirements for Non‐Fullerene‐Based Organic Solar Cells with Power Conversion Efficiency >20%, Advanced Science (2019). DOI: 10.1002/advs.201802028 , dx.doi.org/10.1002/advs.201802028