A new spin on an old technology cools air without adding humidity at a fraction of the energy cost

It is a truth universally acknowledged that the Earth's average temperature is rising—nine of the ten warmest years ever recorded in National Oceanic and Atmospheric Administration National Oceanic and Atmospheric Administration (NOAA)'s 140-year tracking history have occurred since 2005. Warmer temperatures bring with them greater demand for air conditioning, which requires immense amounts of energy. Every year, the United States consumes more electricity for cooling buildings than the entire continent of Africa consumes for all of its electricity needs. In addition to warmer temperatures, a growing middle class worldwide now has disposable income to spend on air conditioning. Experts predict that as a result, global demand (and, therefore, energy use) will more than triple by 2050.

Our desire to beat the heat is nothing new; humans have been finding creative ways to keep cool for millennia. One of the simplest methods of cooling hot air is to put it in contact with water, which absorbs heat from the air as it evaporates, a process called evaporative cooling (EC). But because EC adds humidity to the air, it works well only in dry, hot climates, like the Middle East and the southwestern United States. In humid areas like the tropics, where nearly half of all humans on the planet live, no effective cooling systems were available until the invention of the first electric air conditioners in the early 20th century. These models use a process called mechanical vapor compression to convert a chemical refrigerant between its liquid and vapor forms, allowing it to both absorb heat from incoming air and remove moisture from it via condensation, providing relief from hot, muggy weather.

The vast majority of today's air conditioners still use mechanical vapor compression, which has not changed much since the 1920s, despite mounting concerns about its effects on the environment and human health. The large amounts of energy required to cycle the refrigerant from a liquid to a vapor and back again are mostly created by burning fossil fuels, which releases greenhouse gases and pollution into the atmosphere. As the use of air conditioners increases, so does the strain on electrical grids, which can cause critical power outages on the hottest days of the year and expose people to dangerously high temperatures. Even more concerning, the refrigerants themselves have a greenhouse effect nearly 10,000 times more potent than carbon dioxide, and their increased use will likely exacerbate the current warming trend, driving even more demand for air conditioning and creating a vicious feedback loop of high temperatures causing even higher temperatures.

A cold blast from the past

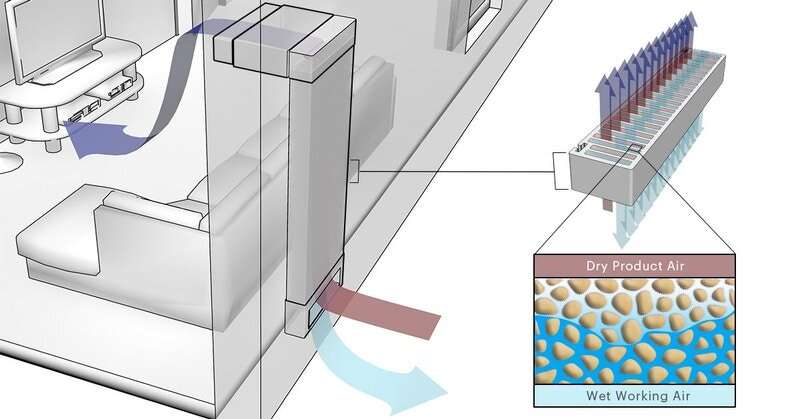

Sometimes in order to make forward progress on a problem, you have to look backward. Around the same time that mechanical vapor compression was invented in the early 20th century, a variant on EC called indirect evaporative cooling (IEC) also debuted in the United States. IEC cools buildings via the evaporation of water as well, but IEC systems contain a heat exchange unit that isolates the evaporating water from the air that is directed inside the building, thus removing heat from it without adding humidity to it. IEC systems require very little energy to run, but are difficult to manufacture due to the complexity of the heat exchange unit, which makes them expensive and their performance difficult to optimize. As a result, they have remained a distant second fiddle to mechanical vapor compression units, which dominate the market.

Jack Alvarenga, M.S. and Jonathan Grinham, D.Des. are working to change that by infusing 21st-century technology into IEC systems, allowing them to effectively cool air at low cost in both humid and dry climates. Their technology, dubbed cold-SNAP (short for cold Superhydrophobic Nano-Architectured Process), uses up to 75% less energy than mechanical vapor compression air conditioners, and relies on water rather than environment-damaging refrigerants.

"The impact that cold-SNAP can have globally is twofold: first, its projected low cost will allow people in poorer areas to afford effective cooling; and second, its low energy requirement will help bring down overall electricity use as people switch or upgrade their aging A/C systems, which will help mitigate further temperature increases," said Grinham, a former graduate student at the Wyss Institute who is now a Lecturer and Research Associate at the Harvard Graduate School of Design.

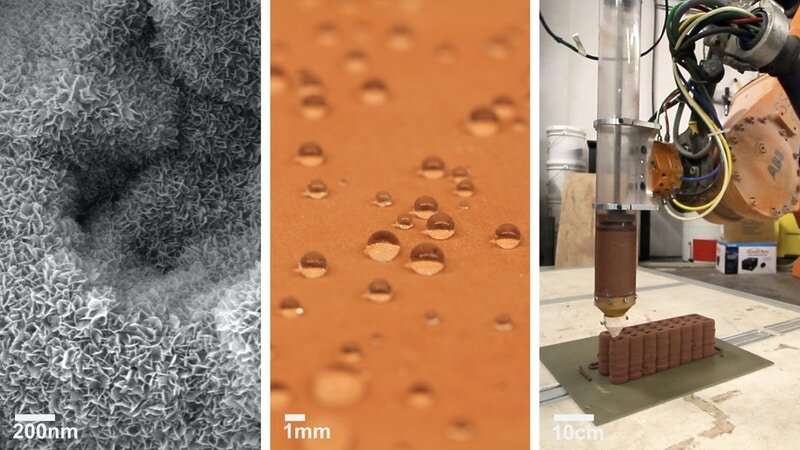

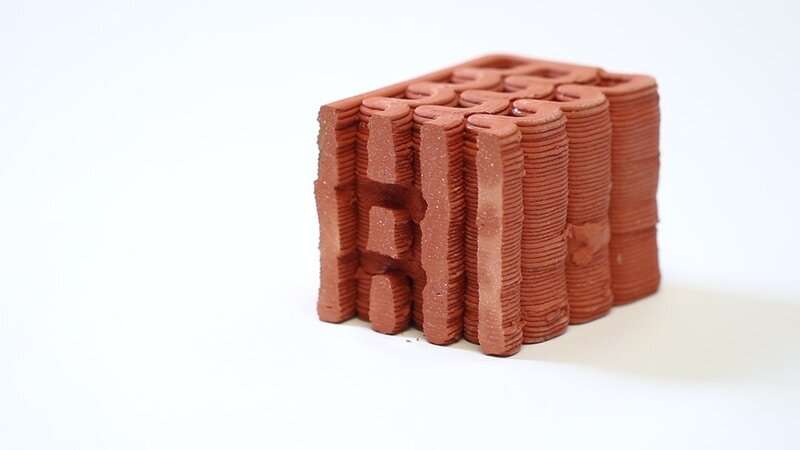

cold-SNAP achieves its high performance thanks to the integration of old and new: ceramic, one of the earliest, cheapest, and most widely available building materials; and a novel surface coating developed recently in the lab of Wyss Core Faculty member Joanna Aizenberg, Ph.D. The coating's nanoscale roughness makes it super water-repellent and, when applied to a slab of highly water-absorbent ceramic, the result is a very efficient heating exchange unit that can effectively isolate evaporating water from cooled air. Because ceramic is very malleable, an entire heating exchange unit can be produced via the extrusion or 3-D printing of a single piece, and its shape can be adjusted to maximize the surface area available for heat transfer and evaporation. The hydrophobic coating is then selectively applied to the components that will manage the flow of dry air, coupled to a water pump, fan, and controls, and voilá: cold-SNAP.

Helping HVAC go green

With additional support from the Harvard University Climate Change Fund, The Harvard Center for Green Buildings and Cities, and industrial partners, Alvarenga and Grinham are forging ahead on their quest to bring green cooling to the world. Preliminary studies have indicated that the cold-SNAP system can be up to four times more efficient than conventional air conditioners as measured by the Coefficient of Performance (COP), which is the ratio of how much useful cooling a system provides over the amount of energy required to produce that cooling. The better a system's COP, the less energy it consumes, and the lower its operating cost. This aspect is crucial, not only so that cold-SNAP can compete with today's conventional air conditioners, but also because the world's poorest people live along the equator, where air conditioning is most needed but electricity is prohibitively expensive.

"HVAC is a really outdated business that hasn't changed much over the last 50 years, because for a long time nobody really factored in the hidden costs of its environmental impact. Now, we're seeing a shift and informed consumers are choosing greener alternatives in many areas of their lives. We want to be able to offer cold-SNAP as a radically different approach to cooling that isn't just cheaper, it's better for the planet, too." said Alvarenga, who is a Research Scientist at the Wyss Institute.

Based on its promise in controlled tests, in 2019 cold-SNAP was named Wyss Institute Validation Project, a program that aims to de-risk technologies and demonstrate that they can be successfully scaled up for commercialization. The team is currently exploring different manufacturing techniques, and is gearing up for a pilot study this summer to see how the system performs in real-world hot and humid conditions.