Microscopic robots 'walk' thanks to laser tech

A Cornell University-led collaboration has created the first microscopic robots that incorporate semiconductor components, allowing them to be controlled—and made to walk—with standard electronic signals.

These robots, roughly the size of paramecium, provide a template for building even more complex versions that utilize silicon-based intelligence, can be mass produced, and may someday travel through human tissue and blood.

The collaboration is led by Itai Cohen, professor of physics, Paul McEuen, the John A. Newman Professor of Physical Science and their former postdoctoral researcher Marc Miskin, who is now an assistant professor at the University of Pennsylvania.

The team's paper, "Electronically Integrated, Mass-Manufactured, Microscopic Robots," published in Nature.

The walking robots are the latest iteration, and in many ways an evolution, of Cohen and McEuen's previous nanoscale creations, from microscopic sensors to graphene-based origami machines.

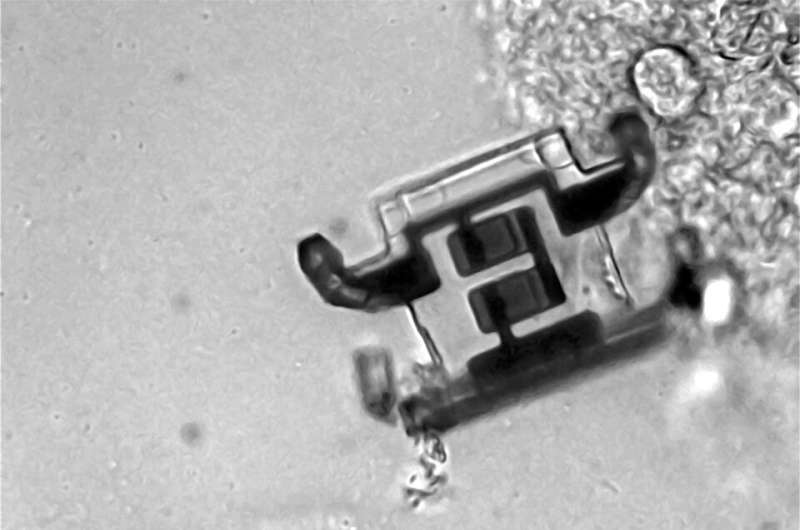

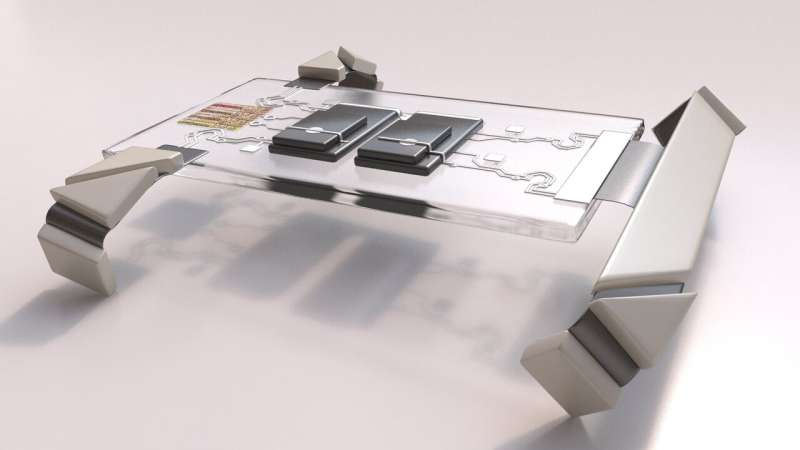

The new robots are about 5 microns thick (a micron is one-millionth of a meter), 40 microns wide and range from 40 to 70 microns in length. Each bot consists of a simple circuit made from silicon photovoltaics—which essentially functions as the torso and brain—and four electrochemical actuators that function as legs.

The researchers control the robots by flashing laser pulses at different photovoltaics, each of which charges up a separate set of legs. By toggling the laser back and forth between the front and back photovoltaics, the robot walks.

The robots are certainly high-tech, but they operate with low voltage (200 millivolts) and low power (10 nanowatts), and remain strong and robust for their size. Because they are made with standard lithographic processes, they can be fabricated in parallel: About 1 million bots fit on a 4-inch silicon wafer.

The researchers are exploring ways to soup up the robots with more complicated electronics and onboard computation—improvements that could one day result in swarms of microscopic robots crawling through and restructuring materials, or suturing blood vessels, or being dispatched en masse to probe large swaths of the human brain.

"Controlling a tiny robot is maybe as close as you can come to shrinking yourself down. I think machines like these are going to take us into all kinds of amazing worlds that are too small to see," said Miskin, the study's lead author.

"This research breakthrough provides exciting scientific opportunity for investigating new questions relevant to the physics of active matter and may ultimately lead to futuristic robotic materials," said Sam Stanton, program manager for the Army Research Office, an element of the Combat Capabilities Development Command's Army Research Laboratory, which supported the research.

More information: Electronically integrated, mass-manufactured, microscopic robots, Nature (2020). DOI: 10.1038/s41586-020-2626-9 , www.nature.com/articles/s41586-020-2626-9