Credit: Ecole Polytechnique Federale de Lausanne

Managing the heat generated in electronics is a huge problem, especially with the constant push to reduce the size and pack as many transistors as possible in the same chip. The whole problem is how to manage such high heat fluxes efficiently. Usually, electronic technologies, designed by electrical engineers, and cooling systems, designed by mechanical engineers, are done independently and separately. But now, EPFL researchers have quietly revolutionized the process by combining these two design steps into one: They've developed an integrated microfluidic cooling technology together with the electronics that can efficiently manage the large heat fluxes generated by transistors. Their research, which has been published in Nature, will lead to even more compact electronic devices and enable the integration of power converters, with several high-voltage devices, into a single chip.

The best of both worlds

In this ERC-funded project, Professor Elison Matioli, his doctoral student Remco Van Erp, and their team from the School of Engineering's Power and Wide-band-gap Electronics Research Laboratory (POWERLAB), began working to bring about a real change in designing electronic devices by conceiving the electronics and cooling together, right from the beginning. The group sought to extract the heat very near the regions that heat up the most in the device. "We wanted to combine skills in electrical and mechanical engineering in order to create a new kind of device," says Van Erp.

The team was looking to solve the issue of how to cool electronic devices, and especially transistors. "Managing the heat produced by these devices is one of the biggest challenges in electronics going forward," says Elison Matioli. "It's becoming increasingly important to minimize the environmental impact, so we need innovative cooling technologies that can efficiently process the large amounts of heat produced in a sustainable and cost-effective way."

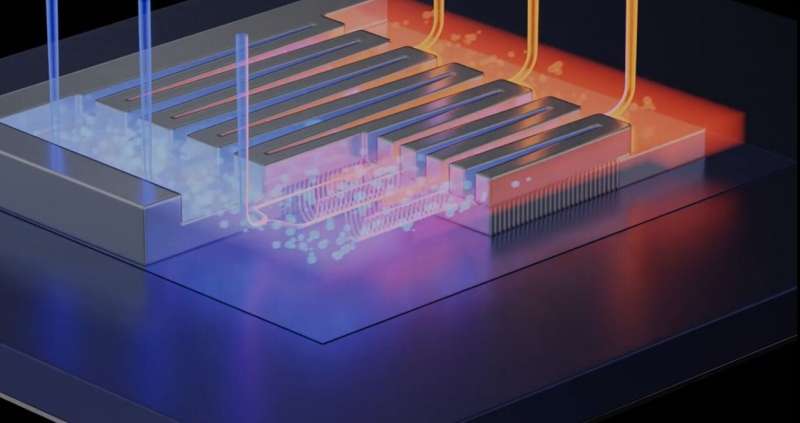

We placed microfluidic channels very close to the transistor's hot spots, with a straightforward and integrated fabrication process, so that we could extract the heat in exactly the right place and prevent it from spreading throughout the device. Credit: EPFL 2020

Microfluidic channels and hot spots

Their technology is based on integrating microfluidic channels inside the semiconductor chip, together with the electronics, so a cooling liquid flows inside an electronic chip. "We placed microfluidic channels very close to the transistor's hot spots, with a straightforward and integrated fabrication process, so that we could extract the heat in exactly the right place and prevent it from spreading throughout the device," says Matioli. The cooling liquid they used was deionized water, which doesn't conduct electricity. "We chose this liquid for our experiments, but we're already testing other, more effective liquids so that we can extract even more heat out of the transistor," says Van Erp.

Reducing energy consumption

"This cooling technology will enable us to make electronic devices even more compact and could considerably reduce energy consumption around the world," says Matioli. "We've eliminated the need for large external heat sinks and shown that it's possible to create ultra-compact power converters in a single chip. This will prove useful as society becomes increasingly reliant on electronics." The researchers are now looking at how to manage heat in other devices, such as lasers and communications systems.

More information: Co-designing electronics with microfluidics for more sustainable cooling, Nature (2020). DOI: 10.1038/s41586-020-2666-1 , www.nature.com/articles/s41586-020-2666-1

Journal information: Nature

Provided by Ecole Polytechnique Federale de Lausanne