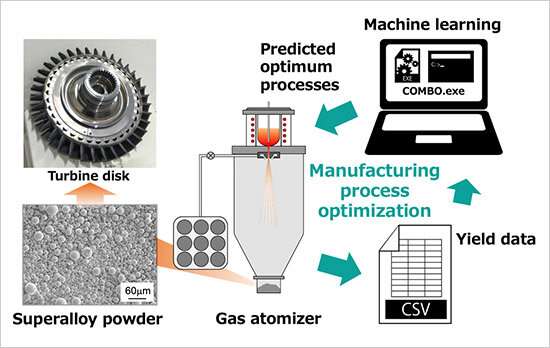

Figure 1. Optimization of superalloy powder manufacturing processes using machine learning. Credit: National Institute for Materials Science

High-performance, high-quality Ni-Co-based superalloy powders are promising aircraft engine raw materials. Using machine learning, a NIMS team has succeeded in speedily determining the optimum parameters for manufacturing these types of powders at high yields. The team then demonstrated that these parameters actually led to the low-cost manufacturing of powders suitable for high-pressure turbine disk production. The use of this technique may significantly reduce the cost of practical, large-scale manufacturing of superalloy powders.

Metal 3-D printing has been rapidly adopted in aerospace engine production, leading to growing demand for low-cost manufacturing and supply of the alloy powders these printing techniques require. When these materials are used in the production of high-pressure turbine disks—a core engine component—they need to meet particularly rigorous requirements: they have to be heat-resistant, highly plastic, high-quality and homogeneous superalloy powders that can be processed into spheres. They also need to be produced at high yields to reduce costs. In practical manufacturing settings, superalloy powders are commonly produced for this purpose using large gas atomizers. It is therefore important to optimize a number of manufacturing parameters, such as the temperatures used to melt metals and the gas pressures. However, this optimization process has proven to be enormously costly, time-consuming and labor-intensive even with the assistance of knowledgeable and experienced experts.

This research team used machine learning in an attempt to optimize gas atomization processes for the manufacturing of Ni-Co-based superalloy powders suitable for high-pressure turbine disk production without relying on the knowledge of experts. As a result, the team succeeded in manufacturing fine-grained powders that can be processed into spheres. In addition, use of the parameters dramatically increased production yields from the conventional 10 to 30% to approximately 78% after performing experiments only six times without using previously collected data. The powder manufactured in this research was approximately 72% cheaper than commercially available powders when the prices of the raw materials were compared.

After years of R&D, NIMS has developed techniques for designing superalloys with controlled physical properties, such as heat resistance. The combined use of these techniques and the parameter optimization technique developed in this research is expected to enable low-cost production of functional superalloy powders designed to meet specific purposes. The prediction accuracy of machine learning models increases as they receive more training data. Superalloy powder manufacturers in the private sector possess largely unexploited manufacturing process data. Integrating this data may further improve the ability of our technique to predict optimum parameters, potentially enabling the manufacturing of higher-quality powders at lower cost.

This research was published in Materials & Design, an open-access journal.

More information: Ryo Tamura et al. Machine learning-driven optimization in powder manufacturing of Ni-Co based superalloy, Materials & Design (2020). DOI: 10.1016/j.matdes.2020.109290

Provided by National Institute for Materials Science