Smarter production methodology: From design freedom to a sustainable environment

The past decade has seen increased prominence for new, more sustainable production methodologies. Selective laser sintering (SLS), an additive manufacturing (AM) technology, is one of those upcoming production methodologies, but its end products suffer from inconsistently reproducible properties. Ph.D. candidate Prakhyat Hejmady from the TU/e Department of Mechanical Engineering has developed an experimental methodology which can offer new possibilities in tailoring this production technique. He defended his Ph.D. thesis on 4 February 2021.

The advent of AM, also commonly known as 3-D printing, has enabled manufacturing of complex and intricate designs without the constraints imposed by traditional manufacturing techniques. SLS is a powder-based AM technique, were products are manufactured layer by layer, using laser as a heat source to locally fuse polymeric powder particles. AM's design freedom both shortens the development cycle and significantly reduces material waste, making it a sustainable alternative. Manufacturers of every size view it as a complement to existing, traditional manufacturing methods.

New materials

To transition from prototyping to widespread mass manufacturing, optimization of SLS is still needed. The current SLS process lacks in reproducibility and is limited by the low availability of usable material types. This limits its use in producing parts with the desired mechanical and functional properties. Therefore, new materials have to be explored, for which the process conditions have to be optimized accordingly. Currently, the optimization process is done on a trial basis, with little to no information on the underlying mechanism during the laser sintering process.

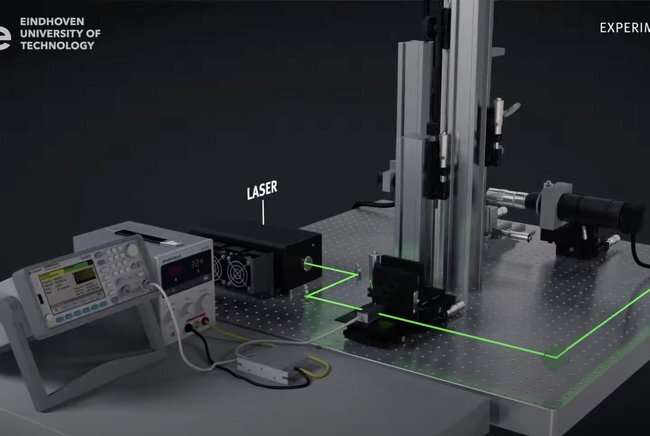

In his Ph.D. research, Hejmady developed a unique experimental setup which allows in-situ visualization studies of laser sintering of polymer particles. This one-of-a-kind setup, developed in-house, visualizes the sintering process by optical imaging, infra-red imaging and X-ray scattering in real time. The setup inherits main features of a SLS machine, allowing researchers to replicate the process and to understand fundamental aspects underlying the sintering process.

These possibilities provide crucial information which was not accessible until now with commercial machines. Optimized process parameters, from laser parameters to particle morphology, gives the initial condition set to be used in an actual machine. A patented, simple, cost effective method was developed to produce spherical polymeric particles, further enhancing the possibility of increasing the reliability of the SLS production technique.

This work provides a stepping stone for developing and testing new materials with the desired functionalized properties. This is an important step towards a more realistic optimization approach and broadening the scope of the SLS AM process.