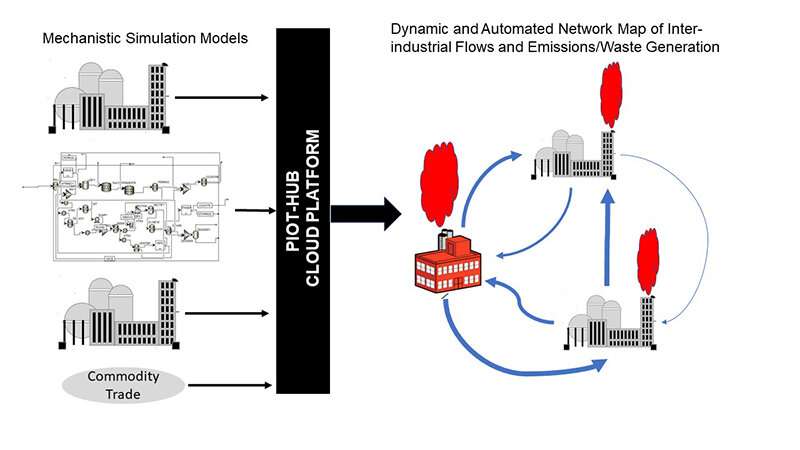

A Purdue University engineering innovator has developed a cloud-based platform aimed at mapping inter-industry dependence networks for materials and waste generation among manufacturers in sectors such as chemicals, pharmaceuticals and other industries tied to biobased economies. Credit: Purdue University/Shweta Singh

A Purdue University engineering innovator has developed a cloud-based platform aimed at mapping inter-industry dependence networks for materials and waste generation among manufacturers in sectors such as chemicals, pharmaceuticals and other industries tied to biobased economies.

Shweta Singh, an assistant professor in Purdue's College of Engineering, led a team that developed a new method for automated creation of physical input-output tables to track flows in manufacturing networks.

PIOTs provide a detailed mapping of inter-industrial dependence to meet a manufacturing target that can help determine economic and environmental outcomes for various manufacturing pathways based on material requirements.

"Unlike current technologies that use tiered data flow systems or time series approximations to fill data bandgaps, our new platform allows for dynamic changes in manufacturing network via mechanistic models developed as computer codes or simulation systems to update network structure for industrial interactions," Singh said. "The goal of this technology is to assist manufacturers to track the materials flow and supply network demand to optimize the process and reduce overall waste, as well as assist in the decision-making process to pick the most sustainable and resilient technology in any supplier network."

Singh said the algorithms in this bottom-up modular model help to map resource flows with enhanced accuracy and reliability as data can be more easily reconciled based on mechanistic models through this approach. She added that the platform offers a collaborative, cloud-based environment that may have applications for the pharmaceutical, food and chemical processing industries.

Provided by Purdue University