Engineers improve the technology of high-performance concrete casting in winter

At low temperatures, concrete tends to set unevenly, which can lead to a collapse. A team of engineers from RUDN University suggested using infrared light and adding silicon and ash to concrete to solve this issue. The technology can be used for cast-in-situ construction. The results of the study were published in the Fibers journal.

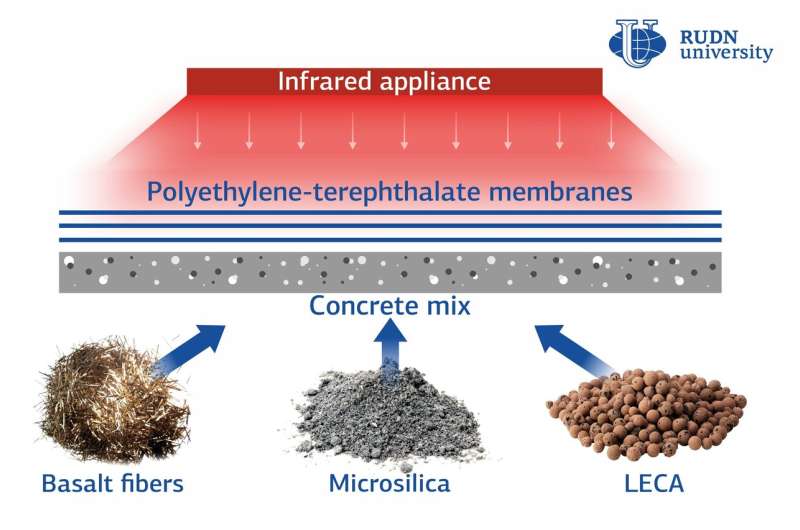

Keramzit and basalt fibers are often added to concrete to improve its qualities. Keramzit makes concrete lighter and increases its heat conductivity, while basalt fibers make the material less fragile. Both additives help concrete set more evenly even at low temperatures. However, in winter it is still not enough, as freezing and thawing cycles cause concrete to deform and split. To avoid this, extra additives and new setting technologies are required. To solve this issue, a team of engineers from RUDN University developed a new type of concrete and suggested heating the mix during setting.

"Concrete casting in winter is an extremely complex process with many technical peculiarities that require additional research. We suggested thermal processing of concrete load-carrying structures used in cast-in-situ construction. Our knowledge of this type of concrete shows that infrared light is able to secure the setting," said Makhmud Kharun, Ph.D., an Assistant Professor at the Department of Construction, Engineering Academy of RUDN University.

Working together with their colleagues from Russia and Nigeria, engineers from RUDN University added microparticles of silicon and ash to the keramzit concrete mixture, thus increasing its compressive strength up to 20 Mpa (i.e., making the concrete able to withstand the pressure of 200 atmospheres). After that, the team added basalt fibers to the mix at the ratios of 1:0, 1:0,0045, 1:0,009, and 1:0,012. Then they grouped the samples of the new concrete by 120 and treated each group with infrared light for 7, 9, 11, 13, 16, or 24 hours. To secure even and efficient heat distribution and moisture levels, the concrete was covered with three layers of a transparent PE-terephthalate membrane. Samples of concrete were analyzed 30 min, 4, 12, and 24 hours after heating and compared to control samples that did not undergo thermal treatment.

After the experimental data were processed using statistical methods, the team found out that heating for seven hours increased the strength of the concrete by about 55%. When subject to heat for a longer period of time, concrete continued to become more durable, however, the improvement was not that dramatic. The increase in strength reached 70% after 11-13 hours of heating and remained unchanged after 24 hours. The engineers also identified the most effective distance between a heating element and the surface of concrete: 1.2 meters with a possible deviation of 15 cm. Additionally, they found out that the improvement of mechanical properties of keramzit concrete by basalt fibers directly correlated with their quantity.

"Experiments with the use of infrared thermal treatment and PE-terephthalate membranes have proven this technology effective for cast-in-situ construction during the cold season, namely, for creating favorable conditions for the setting of concrete. The mathematical models suggested by us help predict the quality of keramzit concrete setting in actual structures," added Makhmud Kharun from RUDN University.

More information: Makhmud Kharun et al. Heat Treatment of Basalt Fiber Reinforced Expanded Clay Concrete with Increased Strength for Cast-In-Situ Construction, Fibers (2020). DOI: 10.3390/fib8110067