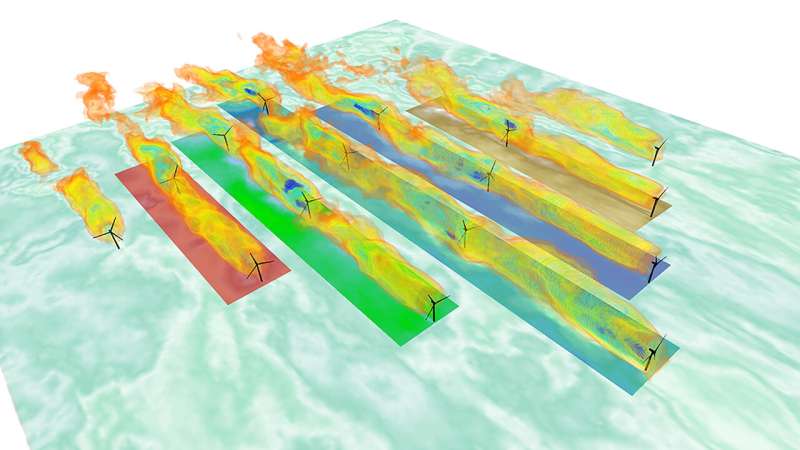

Yellow areas indicate low velocity wakes that extend downstream of wind turbines, and the algorithm identifies clusters of turbines (represented by colored rectangles) that can be optimized as a group to obtain a gain in power production. Credit: University of Texas at Dallas

In the wind power industry, optimization of yaw, the alignment of a wind turbine's angle relative to the horizonal plane, has long shown promise for mitigating wake effects that cause a downstream turbine to produce less power than its upstream partner. However, a critical missing puzzle piece in the application of this knowledge has recently been added—how to automate the identification of which turbines are experiencing wake effects amid changing wind conditions.

In the Journal of Renewable and Sustainable Energy, researchers from the University of Texas at Dallas describe a real-time method for potentially helping turbine farms realize additional power from the clustering of their turbines. Their method requires no new sensors to identify which turbines at any given time could increase power production if yaw control is applied, and validation studies showed an increase of 1%-3% in overall power gain.

"There was a huge gap in how to determine, automatically, which turbine is in the wake of another in the field with variable wind conditions," said co-author Stefano Leonardi. "This is what we solved. This is our contribution."

Wind farms consist of multiple turbines built close together, each converting kinetic energy into electricity. Optimizing power production from an individual turbine depends on many factors (e.g., stratification, temperature, turbulence, topography, etc.), but optimizing production of the farm as a whole also involves interactions between turbines. A downstream turbine in the wake of another encounters decreased wind, reducing turbine power production up to 60%.

The researchers identified how to create clusters or links between turbines by identifying correlations in data currently collected by turbine sensors. Wind farm owners can then use this automated information to guide employment of a standard procedure for yaw control, based on the past decade of studies about yaw optimization. Each 1% increase in energy production would represent 3 billion kilowatts per year.

"The exciting part about our work is that it matches reality, impacting real people," said co-author Federico Bernardoni. "Operators can use these results to identify when they should apply yaw control, and to which group, to maximize wind power gain."

Since the turbines already have the hardware and sensors, and the land is already committed to the wind farm, any increase in power production using this method would be truly green energy. The method is also unique because it is model-free. It makes no assumptions about current parameters or conditions, minimizing the effects of uncertainty present in current wake models.

"By just making turbines smarter, we're getting more energy from something that already exists," said Leonardi. "Using just simple math, we're increasing energy, so that's a very clean, green 1[%]-3%."

More information: "Identification of wind turbine clusters for effective real time yaw control optimization" Journal of Renewable and Sustainable Energy (2021). aip.scitation.org/doi/10.1063/5.0036640

Journal information: Journal of Renewable and Sustainable Energy

Provided by American Institute of Physics