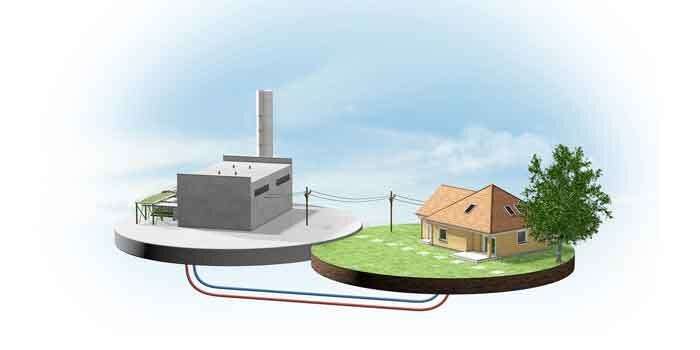

When agricultural surplus biomass such as straw, liquid manure fibres, and deep litter is heated to 5-600°C in an oxygen-depleted environment (pyrolysis), two products occur: biocoal and pyrolysis gas. A small amount of energy is needed to start the pyrolysis. Otherwise, this is a closed circuit that does not require additional energy supply. DTU’s pyrolysis technology requires only 5 per cent of the extracted energy to run. Credit: Claus Lunau

Using pyrolysis, straw and liquid manure can be heated to very high temperatures and become biocoal and gas. The biocoal can be spread on fields and be stored for hundreds of years as part of the CO2 of the biomass. The gas can be utilized for electricity and heat production or be upgraded to aviation fuel.

Straw residues, liquid manure fibers, and deep litter (the material that the livestock stand on in cowsheds and stables, ed.) can be included as important ingredients in a central agricultural climate solution. This was stressed when, in spring, the Government presented its climate and agriculture plan Green Conversion of Agriculture. The technological fulcrum of the solution is pyrolysis. Pyrolysis heats the biomass to very high temperatures in an oxygen-poor environment, thus torrefying the material. The production of torrefied biomass—also called biocoal—is an easy and inexpensive way to capture and store CO2, explains Ulrik Birk Henriksen, senior researcher at DTU Chemical Engineering.

"The carbon capture occurs when the plants absorb the carbon from the atmosphere during the photosynthesis. The first step in the carbon storage takes place when plant residues undergo pyrolysis and are converted into biocoal. Pyrolysis binds up to 50 percent of the carbon from the original biomass in the biocoal. The second step in storage is when the biocoal is spread on farmland—and because biocoal is broken down very slowly—we can potentially store atmospheric CO2 for up to several hundred years," says Ulrik Birk Henriksen.

He adds that researchers from Aarhus University have demonstrated that the biocoal is of further beneficial use in the soil, as it has both a fertilizing effect and improves the soil structure. In addition, pyrolysis also breaks down undesirable substances such as microplastics, hormones, as well as medicine and pesticide residues that have ended up in biomass.

Up to half of the carbon of biomass is ‘captured’ in the biocoal, which can be spread out in the fields where the coal has soil-improving properties. The carbon that the biomass has absorbed from the atmosphere by means of photosynthesis when it was in plant form can be stored in the soil for hundreds of years. Credit: Claus Lunau

A path to fossil-free fuels

Together with his former colleague Jesper Ahrenfeldt, Ulrik Birk Henriksen has worked with pyrolysis for many years at DTU, and the collaboration has now been moved to SkyClean, where Ahrenfeldt is currently employed. Stiesdal Fuel Technologies—headed by Henrik Stiesdal—is behind SkyClean and is investing in upscaling of the pyrolysis plant to accelerate the development of the technology that can reduce carbon emissions in the agricultural sector.

The vision for the pyrolysis technology goes beyond carbon capture and storage. In addition to biocoal, pyrolysis also creates gas, which can be utilized in several ways. The simplest application is to burn the gas to produce electricity and heat. However, pyrolysis gas can also be utilized to produce methanol. In addition, the tar substances can be separated from the pyrolysis gas and be upgraded to oil, which can then be further refined and used for production of liquid fuels for, for example, aircraft.

The pyrolysis gas can be utilized to produce methanol, or tars can be separated from the gas and upgraded to oil. The oil can then be refined further and be used to produce liquid fuels for, for example, aircraft. This requires hydrogen, which can be produced using renewable energy such as wind energy. Credit: Claus Lunau

"In this way, we can replace fossil fuels by means of pyrolysis. However, the solution is still a few years away, because it requires further research and development. But we're really working on it," says Ulrik Birk Henriksen, who believes that this part of the technology can be in place by 2030.

The researcher remains unfazed when mention is made of the criticism that there is not sufficient biomass for pyrolysis to become a significant method for reducing the carbon content of the atmosphere.

The pyrolysis gas can also be burned to produce heat and electricity. Credit: Claus Lunau

"There are loads of surplus biomass in the Danish agricultural sector. We've made calculations on this. However, it's true that biomass is a scarce resource, so it must be used appropriately, and we believe that this is the case here. Because—with pyrolysis—we can effectively remove and store CO2 from the atmosphere in a very inexpensive way," says Ulrik Birk Henriksen.

The Government's proposal for a green conversion of the agricultural sector envisions total a CO2 reduction in the agricultural sector of 7.1 million tons of CO2 equivalents by 2030. Pyrolysis technology accounts for the largest contribution in this process, as—according to the Government's calculations—pyrolysis ensures Denmark a reduction totalling two million tons of CO2 equivalents.

Provided by Technical University of Denmark