Self-fusing edges enables Exoform to be reshaped and reworn on different parts of the body. Credit: Carnegie Mellon University College of Engineering

Each year, roughly 6 million Americans break a bone and head to their doctor for a plaster or fiberglass cast. After six long weeks of keeping the cast dry and resisting the urge to scratch the skin underneath, the patients return to their doctor to have the cast removed and tossed into the trash, unable to be used again. Mohammad Islam, Lining Yao and Carmel Majidi have created a new material system that could change this standard in orthopedics—ExoForm.

Exoform is a compact, customizable and semi-rigid wearable material with self-fusing edges for immediate, adjustable and repeatable use. It offers the unique ability to specifically conform to individual bodies without dependence on medical professionals. The idea for Exoform originated in the midst of the COVID-19 pandemic, as a facemask that could be 3D printed and self-molded to fit the wearer perfectly. Shortly after, the team realized the material's application could be more broadly utilized and the cast was created.

The Exoform cast distinguishes itself from the orthopedic materials currently available at local pharmacies i.e., finger splints and wristbands, in that it can successfully support a variety of complex body parts and adjust its stiffness throughout the healing process. It is also breathable and can be submerged in water, allowing for a more comfortable wearing experience.

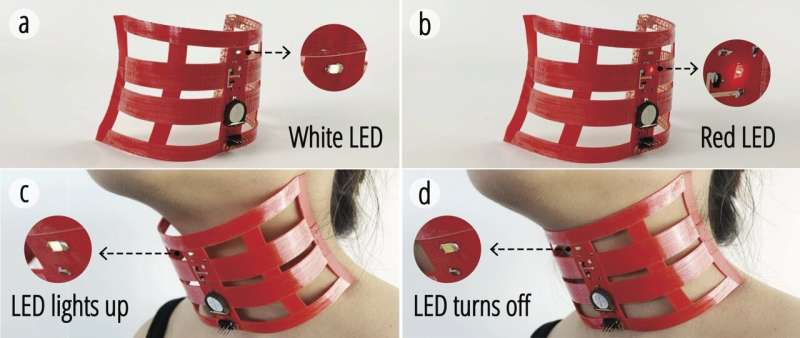

Exoform begins as a flat structure and requires heat—between 70-80 degrees Celsius- to mold. To protect the wearer from burns, users must initially wrap 3 layers of gauze around their skin where they intend to wear the cast. The cast features a sensing and control system that can trigger a white LED light to indicate when the material is at a safe handling temperature. Once heated, the material takes a standardized shape around the body to initialize the rough fit. Users can then manually sculpt the material into their own perfect fit. The white LED light glows brightly and dims as the wearable is tightened.

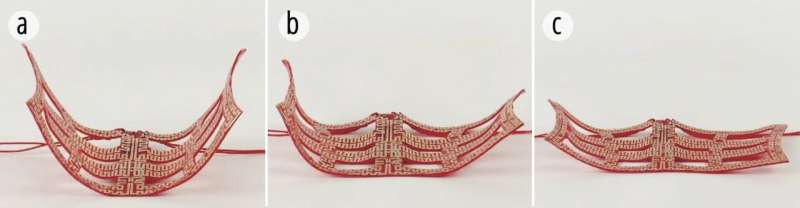

Exoform can be stored flat, saving nearly 95% of the volume taken up by the formed cast. Credit: Carnegie Mellon University College of Engineering

Existing plaster and fiberglass casts remain stiff throughout the course of healing and limits the user's ability to move. This limitation delays the body's natural healing time. With Exoform, as the body begins to heal, the wearer can remove parts of the cast to loosens the material, allowing for increased mobility and ultimately a faster healing time. Once fully healed, the user can remove the cast on their own and begin to refuse the material.

LED indicators indicate when temperature is at a safe handling temperature and tightness of fit.

With self-fusing edges, any pieces of the material removed during the molding and healing process can be added back on by pressing the edges together. This enables repeat usage. Within hours of the edges coming into contact, Exoform pieces self-fuse to the original flat form. This flat packing saves nearly 95% of the volume taken up by the assembled cast making it easy for storage in case one day a friend or family member needs a cast of their own. All in all, Exoform's level of accessibility means that future wearable devices can be tailored to fit users' needs without leaving anyone behind.

More information: Fang Qin et al, ExoForm: Shape Memory and Self-Fusing Semi-Rigid Wearables, Extended Abstracts of the 2021 CHI Conference on Human Factors in Computing Systems (2021). DOI: 10.1145/3411763.3451818