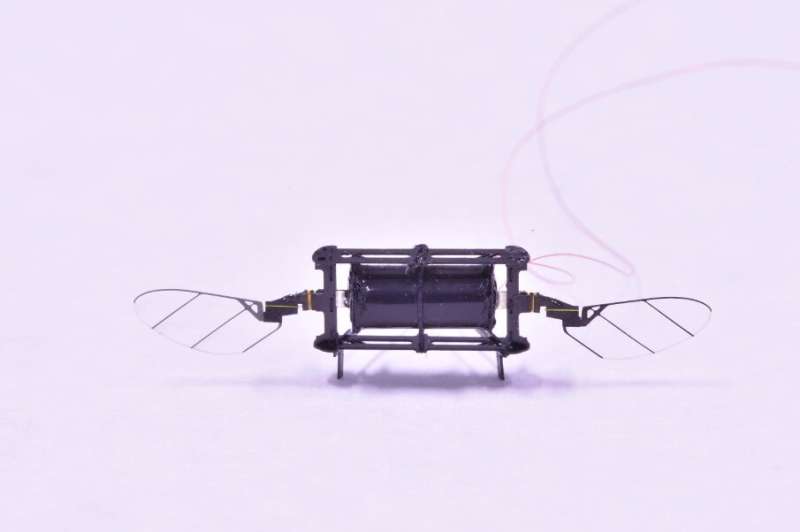

A 0.16 g microscale robot that is powered by a muscle-like soft actuator. Credit: Ren et al.

Micro-sized robots could have countless valuable applications, for instance, assisting humans during search-and-rescue missions, conducting precise surgical procedures, and agricultural interventions. Researchers at Massachusetts Institute of Technology (MIT) have recently created a tiny, flying robot based on a class of artificial muscles known as dielectric elastomer actuators (DEAs).

This new robot, presented in a paper published in Wiley's Advanced Materials journal, significantly outperformed many DEA-based micro-systems developed in the past. Most notably, the robot can operate at low voltages and has high endurance despite its miniature size.

"Our group has a long-term vision of creating a swarm of insect-like robots that can perform complex tasks such as assisted pollination and collective search-and-rescue," Kevin Chen, one of the researchers who carried out the study, told Tech Xplore. "Since three years ago, we have been working on developing aerial robots that are driven by muscle-like soft actuators."

In their previous research, Chen and his colleagues presented several micro robots that could fly remarkably well, performing acrobatic movements in the air and quickly recovering after colliding with other objects. Despite these promising results, the soft actuators underpinning these systems required a high driving voltage of 2 kV, which prevented the robots from operating without an external power supply.

"To fly without wires, the soft actuator needs to operate at a lower voltage," Chen explained. "Therefore, the main goal of our recent study was to reduce the operating voltage of muscle-like DEAs."

A microscale soft robot lands on a flower. Credit: Ren et al.

The actuators underpinning MIT's newly developed sub-gram robot work like a pair of soft capacitors. In other words, when voltage is applied to them, an electrostatic force squeezes the actuators and causes them to deform, similarly to how human and animal muscles contract.

"This small actuator oscillates 400 times every second, and its motion drives a pair of flapping wings, which generate lift force and allow the robot to fly," Chen said. "Compared to other small flying robots, our soft robot has the unique advantage of being robust and agile. It can collide of obstacles during flight and recover and it can make a 360 degree turn within 0.16 seconds."

When developing their robot, Chen and his colleagues drew inspiration from nature and from the intricate biological mechanisms underpinning animal locomotion. Ultimately, they wished to artificially reproduce the flight capabilities of insects, but with a lower driving voltage than that required to operate systems they created in the past.

"Compared to prior work, the driving voltage of soft actuators is reduced from 2kV to 500 V," Chen said. "In addition, the net robot lift increases by 80 percent. With lower operation voltage and more payload, this work opens opportunities for incorporating batteries and power electronics. We believe this work is an important milestone for developing power-autonomous aerial robots powered by soft actuators."

The DEA-based design introduced by this team of researchers could soon pave the way towards the development of increasingly advanced and untethered micro-sized robots. For instance, it could inspire the creation of sophisticated biomimetic robots that can blend into the surrounding environment, including robots that resemble dragonflies or hummingbirds.

"We are now exploring two different research directions," Chen added. "First, we will continue to reduce DEA operating voltage, and our next goal is to reduce it to below 100 V, as this would open up more opportunities for designing miniature circuits. Second, we will design small circuits and batteries for our tiny robot. We hope that one day our robot will carry its own power sources and fly without wires."

More information: High lift micro-aerial-robot powered by low voltage and long endurance dielectric elastomer actuators. Advanced Materials(2021). DOI: 10.1002/adma.202106757.

Journal information: Advanced Materials

© 2021 Science X Network