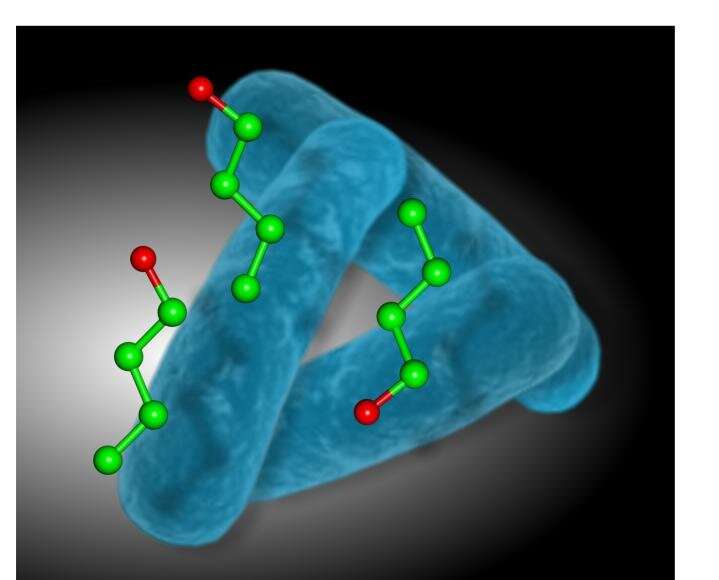

An artistic depiction of Clostridium bacteria producing the biofuel butanol.

Researchers from the University of Kent's School of Biosciences have designed and built equipment that can be used to investigate bacterial biofuel production at a fraction of the cost of commercial systems. This technology was then used to demonstrate that bacterial genetic engineering could be used to enhance biofuel production.

Commercial equipment used to study biofuel-producing bacteria can be prohibitively expensive, which prompted the team to build their own bioreactors that are accessible to most research laboratories. The researchers then used this equipment to verify that one of their genetically engineered variants of Clostridium bacteria could produce the biofuel butanol more rapidly.

These research findings, which have been published in the journals Access Microbiology and Microbial Biotechnology, reveal that a subtle change to a single gene can result in remarkable changes to how sugars are converted to biofuel products.

It is expected that this work will improve accessibility to cheaper bioreactors to stimulate wider research into biofuel production using natural and engineered bacteria.

Corresponding author Dr. Mark Shepherd, Senior Lecturer in Microbial Chemistry at Kent, said that "These exciting developments will help to advance research into bacterial biofuel production, and we are particularly enthusiastic to use our expertise to optimize processes that can convert waste products from food and agriculture into biofuels that are greener alternatives to fossil fuels."

More information: Taylor I. Monaghan et al, Parallel bioreactor system for accessible and reproducible anaerobic culture, Access Microbiology (2021). DOI: 10.1099/acmi.0.000225

Taylor I. Monaghan et al, Deletion of glyceraldehyde‐3‐phosphate dehydrogenase ( gapN ) in Clostridium saccharoperbutylacetonicum N1‐4(HMT) using CLEAVE™ increases the ATP pool and accelerates solvent production, Microbial Biotechnology (2021). DOI: 10.1111/1751-7915.13990

Provided by University of Kent