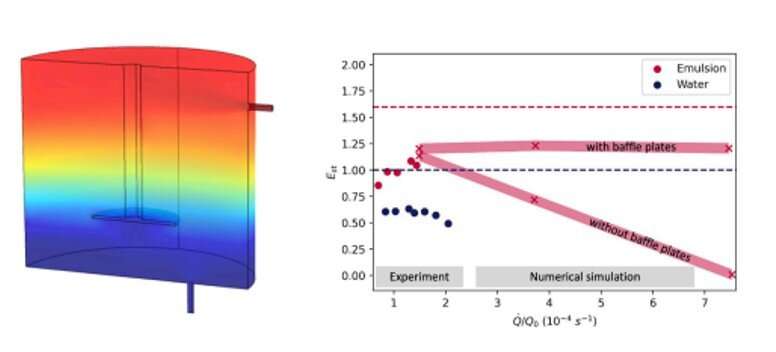

The study included both numerical simulations and experimental investigations. (a) The 3-D numerical model of the phase change emulsion storage tank demonstrating temperature distribution. (b) The energy effective ratio of phase change emulsion and water in the experiment and during simulations with or without baffle plates. Credit: Applied Energy, DOI: 10.1016/j.apenergy.2022.118526

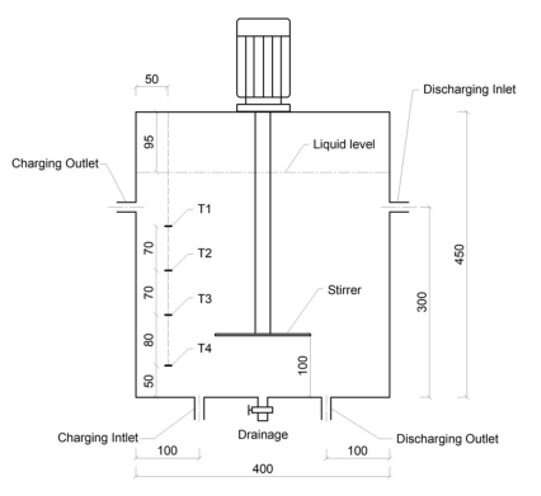

Materials Scientists have shown how phase change materials can improve the energy density in thermal energy storage, although with limits relative to low charging/discharging speeds. In a new report now published in Elsevier's Applied Energy, Haobin Liang, Liu Liu and a team of scientists headed by Yixiang Gan and JianLei Niu in energy engineering and civil engineering at the Hong Kong Polytechnic University, Hong Kong, and the University of Sydney, Australia, presented a new stratified phase change emulsion tank for cold storage. The team conducted both experimental and numerical studies to build radiant cooling applications for cold storage, which they demonstrated with a new, stratified storage tank of phase change materials (PCM) in water nano-emulsion. During the experiments, they used a 20 weight percent PCM-in-water nano-emulsion as the storage medium and heat transfer fluid to obtain increased cooling capacity by 60 percent with phase change emulsion (PCE) circulating in the loop. The numerical simulations indicated how baffle plates installed in the storage tank could reduce fluid mixing to significantly increase the effective energy storage capacity at high discharging flow rates. The newly designed stratified storage tank of PCM-in-water nano-emulsion is comparatively advantageous due to a low temperature difference between the cooling source and demand, to improve the overall efficiency of the energy system.

Building a new phase change emulsion (PCE) storage tank

The demand for renewable energy has increased due to rapid economic growth and social development to meet growing energy consumption and reduced environmental pollution criteria. Since sources of renewable energy, including solar and wind are unstable due to seasonal changes, the possibility of energy storage integration is crucial to balance energy demand and supply. For example, thermal energy storage systems can store energy received during the day, for use at night, for applications in heating, ventilation and air-conditioning (HVAC) systems or to cool electronic devices in data centers.

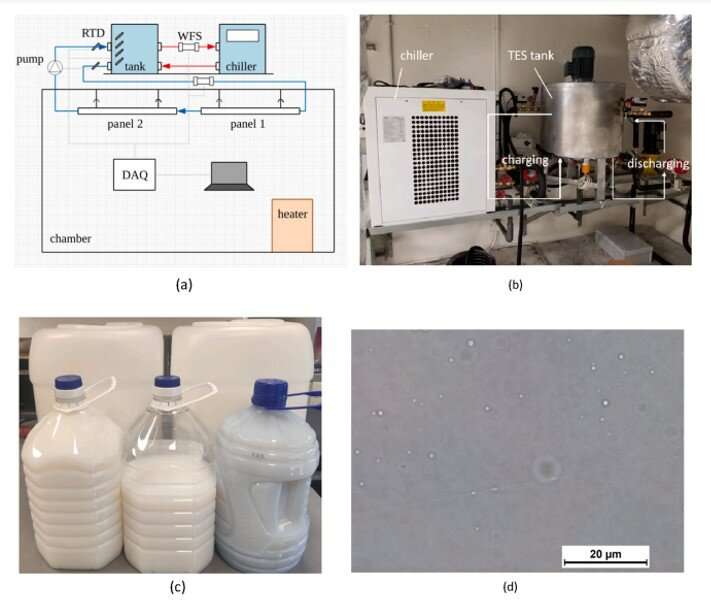

Primary author, Ph.D. researcher Haobin Liang, who is presently completing their doctoral research within the research team of Associate Professor Yixiang Gan at the School of Civil Engineering, University of Sydney, Australia, described their work in the field as 'an innovative thermal energy storage solution." Liang defined the dynamics of the experimental setup: "We used the phase change emulsion storage tank to circulate nano-emulsion and provide dual function to transfer and store heat in the system. This development significantly improved the storage capacity, as well as charging and discharging rates, compared to conventional storage tanks containing either water or phase change materials (PCMs)." Materials scientists have shown that while stratified storage tanks have emerged as a popular choice for thermal energy storage with broad applications, thermal energy can also be improved by submerging phase change materials into the tank structure for improved thermal efficiency. Phase change emulsions are also a storage and heat transfer media of interest, which can be achieved by dispersing droplets of phase change materials in a carrier fluid, such as water, with surfactants for a variety of applications. In this work, Liang et al. devised a new approach to combine PCM (phase change material) emulsion, as the storage media for the new thermal stratification tank—while circulating as the heat transfer media in a cooled ceiling system.

Experimental set-up: (a) schematic diagram (RTD: resistance thermometer detector, WFS: water flowrate sensor, DAQ: data acquisition); (b) photograph of cold storage tank and chiller; (c) phase change emulsion; (d) micrograph of optical microscope. Credit: Applied Energy, DOI: 10.1016/j.apenergy.2022.118526

Experimental setup

During cold storage applications, charging and discharging speeds are crucial, but low thermal conductivity of phase change materials can result in low heat transfer rates, with longer charging/discharging time. To overcome such limits and improve heat transfer of phase change materials, researchers employ a variety of methods including the integration of metal foams and nanoparticles. Liang et al. designed a new approach for phase change material emulsion in the stratification tank to reach a higher discharge rate, with stable effective energy capacity, by introducing baffle plates. The team tested the stratification of the PCM emulsion storage tank, followed by its effective energy efficiency, energy storage and discharge speed. They also developed a numerical model to understand the phase change process within the phase change material emulsion, as a new and promising alternative for thermal energy storage. According to Haobin Liang, the team expect "the type of PCE (phase change emulsion) storage to show great potential in energy efficient buildings to balance the energy supply and demand."

Design parameters of the storage tank. Credit: Applied Energy, DOI: 10.1016/j.apenergy.2022.118526

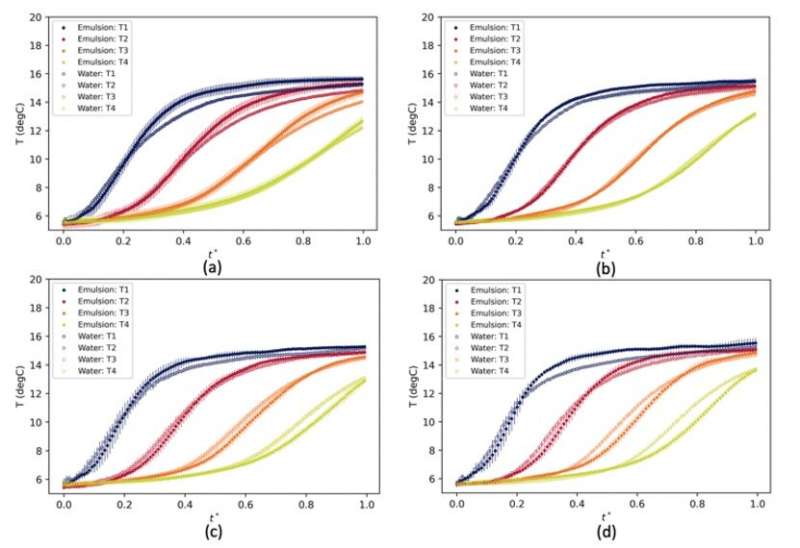

Discharging behavior and stratification performance of the new model.

To illustrate the dynamic discharging behavior of the phase change emulsion stratification tank, Liang et al. analyzed the results of the validated 3D numerical model. They captured the evolution of the phase change within the emulsion, based on the dynamics of phase change materials. Then characterized temperature evolution within the tank under different flow rates and deduced faster evolution of temperature under higher flow rates, where hot and cold fluid mixing was also significant. The numerical models showed the validity of the effective heat capacity method to understand the phase change effect of phase change materials in the emulsion, to improve the concept of thermal stratification with tank design. The team tested both phase change emulsion media and water as storage media to indicate slightly higher effective energy efficiency of the phase change emulsion compared to water, at higher flow rates due to higher viscosity of emulsion, which slowed temperature increase in the outlet. The results highlighted the potential of using emulsion as a new thermal energy storage medium inside the stratification tank.

-

Temperature profiles of phase change emulsion and water storage tanks under different flow rates in experiments: (a) 0.242 L/min; (b) 0.296 L/min; (c) 0.370 L/min; (d) 0.401 L/min. Credit: Applied Energy, https://doi.org/10.1016/j.apenergy.2022.118526

-

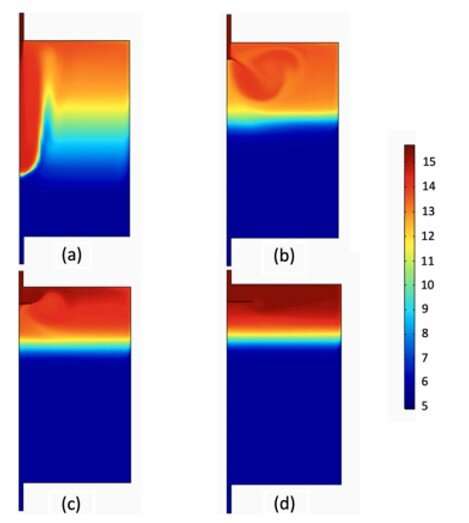

Temperature contours of phase change emulsion under different baffle plate sizes when t * = 0.5, flow rate = 1 L/min (unit: ◦C): (a) dp/dt = 0, no baffle plate; (b) dp/dt = 1; (c) dp/dt = 3; (d) dp/dt = 6. Credit: Applied Energy, DOI: 10.1016/j.apenergy.2022.118526

Outlook

The team further optimized the experimental setup with baffle plates to achieve desirable and effective energy efficiency in phase change emulsion storage, to surpass the quantified dimensions of stratified water storage (SWS) tanks. In this way, Haobin Liang, Liu Liu, and colleagues further described the effective energy ratio of the PCE (phase change emulsion) tank to be greater than the SWS tank, to highlight thermal efficiency of PCM (phase change material) emulsion. Based on the experimental and numerical outcomes, Haobin Liang concludes that this technology "will have applications for emergency cooling of computing devices in rapidly developed data centers," among other practical applications of cold storage with radiant cooling panels.

More information: Haobin Liang et al, Towards idealized thermal stratification in a novel phase change emulsion storage tank, Applied Energy (2022). DOI: 10.1016/j.apenergy.2022.118526

Jason Woods et al, Rate capability and Ragone plots for phase change thermal energy storage, Nature Energy (2021). DOI: 10.1038/s41560-021-00778-w

Journal information: Nature Energy

© 2022 Science X Network