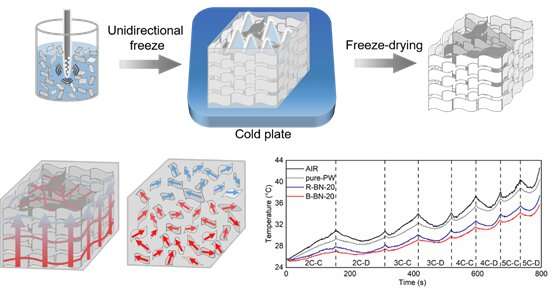

The process the researchers followed to enhance heat dissipation performance management in lithium ion batteries. Credit: Zhejiang University

While electric vehicles have reaped the rewards of new high-energy lithium-ion batteries and rapid charging technology, challenges remain.

For example, although cars can cover longer distances between charges, and battery charging times have reduced, the lifespan of those batteries has also decreased, and low heat dissipation efficiency has led to safety issues.

Researchers from the US and China set out to find an economic but efficient battery thermal management strategy to keep battery temperatures within a safe range. In a study, published in the journal Green Energy & Environment, they shared their findings—a 3D, interconnected, thermally-conductive boron nitride network that greatly improves thermal conductivity compared to random distribution.

Study co-author, Professor Bing Zhang of China's Zhejiang University, explains that they "designed a three-dimensional (3D) network of boron nitride, and systematically studied its effect on the thermal management performance of power cells."

"What we found is that the hexagonal boron nitride thermal network (h-BN) constructed by the ice template method with varying temperature gradients showed structural differences in different directions. Generally, structure determines performance, and different structures in different directions means a greater spread of performance. And by creating a composite with paraffin (h-BN/PW), we could achieve excellent anti-leakage performance and ultra-fast heat dissipation performance in lithium-ion batteries."

He adds that their "results showed that the maximum surface temperature of the battery with continuous charge and discharge at 2 ℃–5 ℃ was reduced by 6.9 ℃ . We think that this demonstrates the great potential of this process for application in battery thermal management systems."

More information: Zhuoya Wang et al, Ultrafast battery heat dissipation enabled by highly ordered and interconnected hexagonal boron nitride thermal conductive composites, Green Energy & Environment (2022). DOI: 10.1016/j.gee.2022.02.007

Provided by KeAi Communications