Online cover—a rigid, 3D printed “island” sits atop a stretchable polymer. Currently, repetitive and excessive strain cause stretchable electronics to fail, limiting their practical use. To remedy this, Yang et al. developed Ferris wheel-shaped islands (FWIs) that withstand the strain of continuous stretching, twisting, poking, and crumpling. Unlike conventional circle- and square-shaped islands in soft polymer matrix, the geometrically engineered FWIs are highly durable. Yang et al.’s approach applies to a wide variety of stretchable electronics and could hasten commercialization in the near future. Credit: Science Advances (2022). DOI: 10.1126/sciadv.abn3863

Stretchable electronics can be developed by integrating rigid components in a soft polymer matrix. However, it is challenging to eliminate cracks at the interface between soft and rigid materials. In a new report now published and illustrated on the cover page of Science Advances, Jun Chang Yang, Seungkyu Lee, and a research team in Materials Science, and Mechanical Engineering at the Korea Advanced Institute of Science and Technology in the Republic of Korea, developed geometrically engineered Ferris wheel–shaped islands to effectively suppress crack propagation at the interface under various deformation modes. The optimized shape showed increased strain at failure and fatigue life compared with conventional shapes, including circle and square-shaped islands. The team showed how the electronic skin could differentiate various tactile stimuli without interference while demonstrating notable enhanced durability to withstand conditions of daily use.

Ferris wheel–shaped islands (FWI)

Stretchable electronics allow a variety of hitherto unknown functions by offering various form factors that are usually incompatible with rigid electronics. For instance, stretchable displays, battery packs and logic circuits are vulnerable to lateral strain and can be protected against mechanical deformation via a variety of engineering strategies. However, mechanical mismatch between rigid islands and polymer materials can lead to interfacial cracks and device dysfunction. To solve this, researchers have devised several strategies. In this work, Yang et al presented geometrically engineered rigid islands with excellent mechanical stability at the interface.

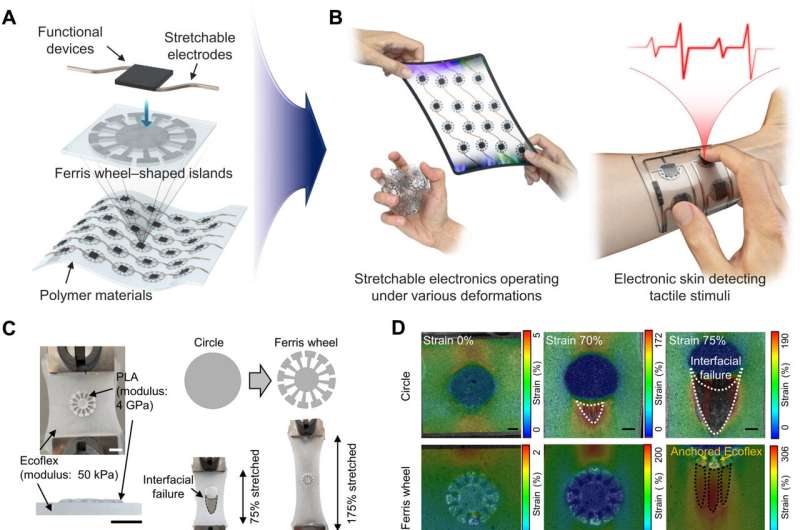

Mechanistically, the interlocking structure of the proposed FWI effectively suppressed crack propagation at the interface. The optimized geometrical shapes relied on the mechanical properties of the constituent polymer materials. By design, the repetitive interlocking structure prolonged the fatigue life against various deformation and stretching modes. The team showed a variety of applications of the array, which they developed using Ecoflex polymer material to show stretchable electronics under various deformations and the formation of electronic skin to detect tactile stimuli with durability for daily use with commercial viability.

FWIs embedded in Ecoflex substrate for highly durable stretchable electronics. (A) Schematic illustration of stretchable electronics with the FWI array in Ecoflex. (B) Left: schematic illustration of stretchable electronics operating under various deformations; right: schematic illustration of electronic skin (e-skin) detecting tactile stimuli. (C) Left: photographs of PLA islands embedded in Ecoflex; right: photographs comparing the maximum stretchability of circle-shaped island (CI) and FWI in Ecoflex substrate. The CI and FWI in Ecoflex are stretched to 75 and 175%, respectively. (D) Digital image correlation (DIC) images showing the progress of crack propagation for the CI and FWI in Ecoflex under stretching. (E) Stress versus strain for the CI (red trace) and FWI (blue trace) in Ecoflex under stretching. (F) The strain at failure according to the angle. The islands are rotated at specific angles, embedded in Ecoflex matrix, and stretched vertically. Scale bars, 1 cm (C) and 5 mm (D). Photo credit: J. C. Yang, Korea Advanced Institute of Science and Technology (KAIST). Credit: Science Advances (2022). DOI: 10.1126/sciadv.abn3863

Developing the FWI embedded in the Ecoflex matrix

Yang et al. used 3D printing to economically manufacture a variety of island shapes. They embedded the printed islands in a polymer matrix, prepared using polylactic acid and Ecoflex, to form an island and polymer, respectively. The FWIs effectively suppressed crack propagation to increase stretchability. The constructs maintained excellent stretchability when compared with various randomly generated shapes. During stretching, to understand crack propagation at the interface, Yang et al used digital image correlation analysis, to obtain the strain distribution of Ecoflex near and on the islands. To derive the FWIs, the team examined the properties of circular shaped islands relative to their stretchability, methods to implement interfacial strength, and the potential to implement mechanical interlocking in the FWIs, to prevent the progression of the cracks via anchored Ecoflex regions.

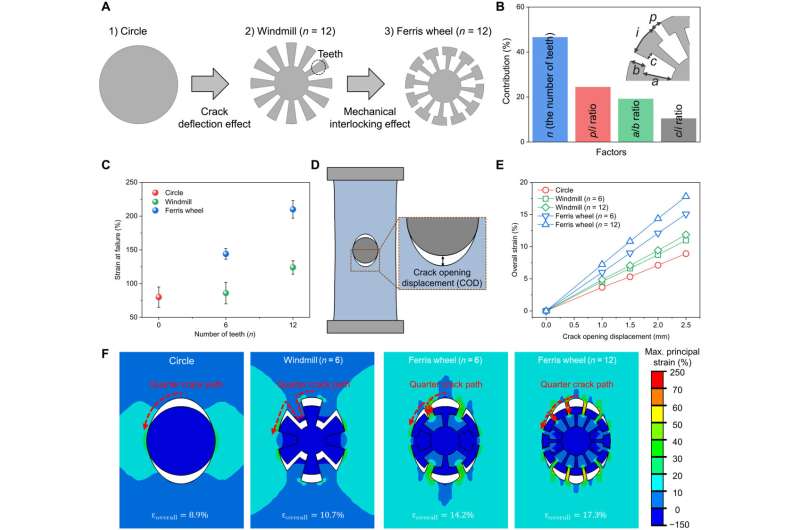

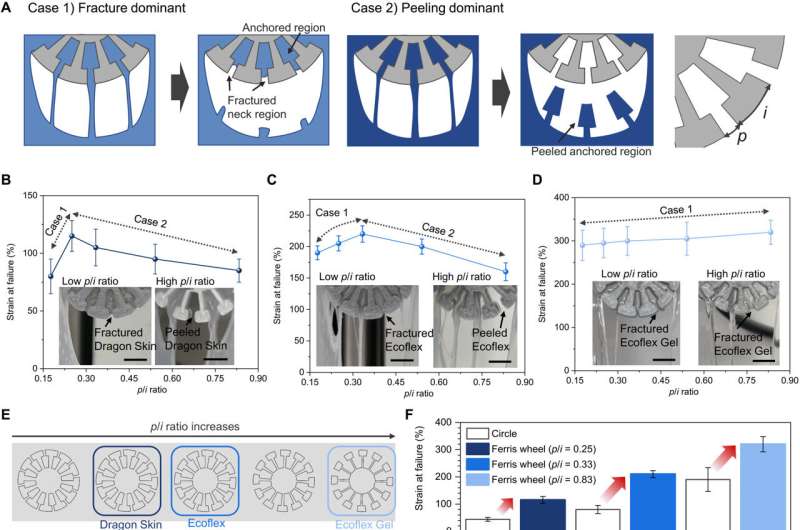

The researchers 3D printed several different FWIs and analyzed them to confirm the number of "teeth" on the device that were assumed to have the greatest impact on the design, where crack propagation differed for each shape. They developed a finite element simulation method to understand the effect of the island designs on its properties and showed how crack propagation could be regulated between the matrix and the island for FWIs of different material constituents. Yang et al tested three materials, including Dragon skin, Ecoflex, and Ecoflex gel, of which, Ecoflex was best suited to form stretchable electronics.

Investigation of interfacial failure caused by crack propagation. (A) Schematic illustration of the process of deriving FWI. (B) Percent contribution of the design factors (the number of teeth, p/i ratio, a/b ratio, and c/i ratio) to the strain at failure. (C) Experimentally obtained strain at failure for CI, WMIs (n = 6 and 12), and FWIs (n = 6 and 12). (D) Schematic illustration of FE-simulated crack propagation between islands and Ecoflex substrate. (E) Overall strain versus crack opening displacement (COD) for CI, WMI (n = 6 and 12), and FWI (n = 6 and 12). (F) FE simulation images showing the process of crack propagation when the COD reaches 2.5 mm. Credit: Science Advances (2022). DOI: 10.1126/sciadv.abn3863

Mechanical reliability of the constituents and E-skin formation

The scientists noted the effective suppression of crack propagation in the device for enhanced stretchability and prolonged fatigue life of the constructs. They tested the properties via fatigue tests to understand how crack propagation resistance contributed to mechanical stability under a variety of 3D deformations. The results indicated how geometric designs influenced stretchable electronics to propel devices towards a variety of practical applications. The researchers developed the stretchable electronics in the form of an array and encapsulated them with Ecoflex. The construct functioned well across a range of deformation modes for user convenience and durability.

The material can be used for a range of applications, including virtual augmented reality, human-machine interfaces and robotics, under repeated and excessive mechanical deformation. Yang et al used four polypyrrole-coated micropyramidal, polydimethylsiloxane-based piezoresistive pressure sensors on the FWIs, alongside two porous carbon nanotubes and Ecoflex composite-based piezoresistive strain sensors coated on the Ecoflex. They included scanning electron microscopy images and confirmed the appearance of the microstructures. As proof of concept, the team gathered information on daily movements of subjects by using the device to monitor health care via a sensor attached to the knee. Upon attachment, the team decoupled the complex tactile stimuli with simultaneous input of strain and pressure in real-time.

-

Compatibility of FWIs with various polymer materials. (A) Schematic illustration of two types of complete interfacial failure in FWI in polymer substrate. (B to D) Strain at failure according to the p/i ratio change of (B) Dragon Skin, (C) Ecoflex, and (D) Ecoflex Gel. (E) Schematic illustration of FWIs with different p/i ratios. Each box represents the optimized FWI of each polymer. (F) Experimentally obtained strain at failure for CI (white bars) and FWI (blue bars) in three different polymer matrices (Dragon Skin, Ecoflex, and Ecoflex Gel). Scale bars, 5 mm (B to D). Photo credit: J. C. Yang, KAIST. Credit: Science Advances (2022). DOI: 10.1126/sciadv.abn3863

-

Stretchable electronics consisting of rigid components capable of withstanding various deformation modes. (A) Schematic illustration, photograph, and SEM image of stretchable Ag flake/Ecoflex electrodes printed on the FWI in Ecoflex substrate. (B) Resistance versus lateral strain for the Ag flake/Ecoflex electrodes printed on CI and FWI in Ecoflex. The left inset shows that the electrode printed on CI in Ecoflex was disconnected at 50%. The middle and right insets show that the electrode printed on FWI in Ecoflex was connected at 125 and 220%, respectively. (C and E) Schematic illustration and photograph of (C) a stretchable LED array and (E) stretchable battery pack with FWIs. The encapsulation layer is Ecoflex. (D and F) Photographs of (D) the stretchable LED array and (F) the stretchable battery pack capable of withstanding various deformation modes (twisting, bending, stretching, and crumpling). Scale bars, 1 cm [(A), left image], 10 μm [(A), right image], 3 cm (C), and 4 cm (E). Photo credit: J. C. Yang, KAIST. Credit: Science Advances (2022). DOI: 10.1126/sciadv.abn3863

Outlook: Electronic skin

In this way, Jun Chang Yang, Seungkyu Lee, and colleagues developed stretchable electronics for high durability. They engineered FWIs with strong mechanical stability at the interface with accompanying soft polymers. The construct improved strain at failure and prolonged the fatigue life under a range of deformation modes. The FWIs have significant influence on mechanical stability of the substrate depending on the mechanical properties of the polymer constituents. The team used the constructs in practice as stretchable electronics by printing intrinsically stretchable electrodes and placing rigid components on the FWI array, and they developed the electronic-skin to differentiate a variety of physical stimuli. The outcome is applicable for high durability under varying deformation modes, to facilitate the commercialization of electron skins or stretchable electronics in the near future.

More information: Jun Chang Yang et al, Geometrically engineered rigid island array for stretchable electronics capable of withstanding various deformation modes, Science Advances (2022). DOI: 10.1126/sciadv.abn3863

Sihong Wang et al, Skin electronics from scalable fabrication of an intrinsically stretchable transistor array, Nature (2018). DOI: 10.1038/nature25494

Journal information: Science Advances , Nature

© 2022 Science X Network

![Stretchable electronics consisting of rigid components capable of withstanding various deformation modes. (A) Schematic illustration, photograph, and SEM image of stretchable Ag flake/Ecoflex electrodes printed on the FWI in Ecoflex substrate. (B) Resistance versus lateral strain for the Ag flake/Ecoflex electrodes printed on CI and FWI in Ecoflex. The left inset shows that the electrode printed on CI in Ecoflex was disconnected at 50%. The middle and right insets show that the electrode printed on FWI in Ecoflex was connected at 125 and 220%, respectively. (C and E) Schematic illustration and photograph of (C) a stretchable LED array and (E) stretchable battery pack with FWIs. The encapsulation layer is Ecoflex. (D and F) Photographs of (D) the stretchable LED array and (F) the stretchable battery pack capable of withstanding various deformation modes (twisting, bending, stretching, and crumpling). Scale bars, 1 cm [(A), left image], 10 μm [(A), right image], 3 cm (C), and 4 cm (E). Photo credit: J. C. Yang, KAIST. Credit: Science Advances (2022). DOI: 10.1126/sciadv.abn3863 Geometrically engineered rigid island array for stretchable electronics](https://scx1.b-cdn.net/csz/news/800a/2022/geometrically-engineer-4.jpg)