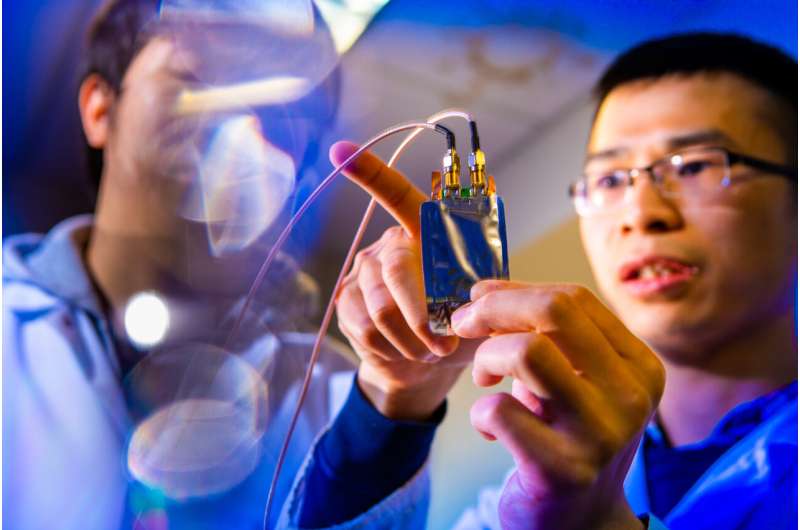

Yulong Huang (right) holds a lithium-ion battery with a cathode made from magneto-ionic material. Huang and Zheng Li (left), both UB postdoctoral researchers in mechanical and aerospace engineering, are among authors of a new study on the magneto-ionic material. Credit: Douglas Levere / University at Buffalo

A new study shows how a magnetic material can be used to help monitor the amount of life left in a rechargeable battery before it needs to be recharged.

Shenqiang Ren, a scientist and engineer at the University at Buffalo, led the project and explains how the system works.

As lithium-ion batteries charge and discharge, lithium ions flow from one side of the battery to the other. With this in mind, Ren's team built a lithium-ion battery that uses a special material at one end: a compound whose magnetism changes as lithium ions enter or leave it. This makes it possible to measure the battery's level of charge by tracking changes in the material's magnetism, Ren says.

The research was published on June 13 in the Proceedings of the National Academy of Sciences (PNAS).

"The main goal of this project was working on the magneto-ionics, which uses ions to control the magnetism of materials. As the lithium ions travel in or out of the material we are using, the material will change its magnetization. We can monitor the magnetism, and this enables us to indirectly monitor the lithium ions—the state of charge. We believe this is a new way to provide an accurate, fast, responsive sensing of state of charge," says Ren, Ph.D., UB professor of mechanical and aerospace engineering, and of chemistry, and a core faculty member in the UB RENEW Institute.

-

A sample of the magneto-ionic material used in a new study. Credit: Douglas Levere / University at Buffalo

-

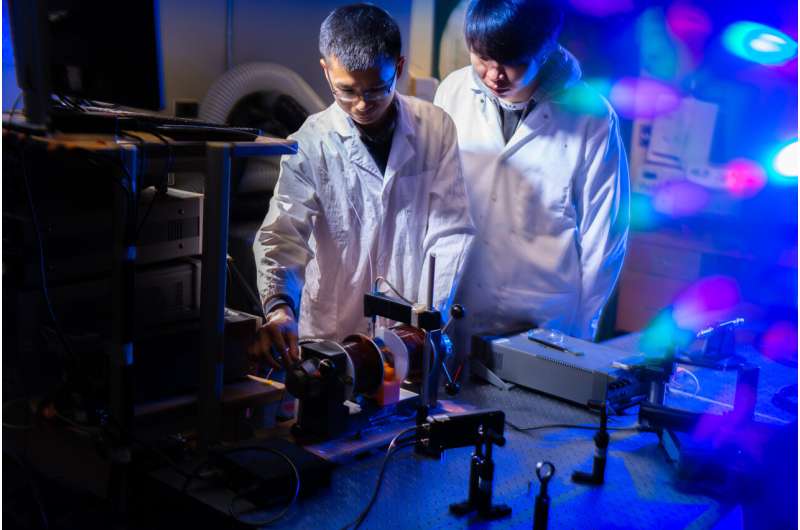

From left: Yulong Huang and Zheng Li, both UB postdoctoral researchers in mechanical and aerospace engineering, are among authors of a new study on magneto-ionics. Credit: Douglas Levere / University at Buffalo

-

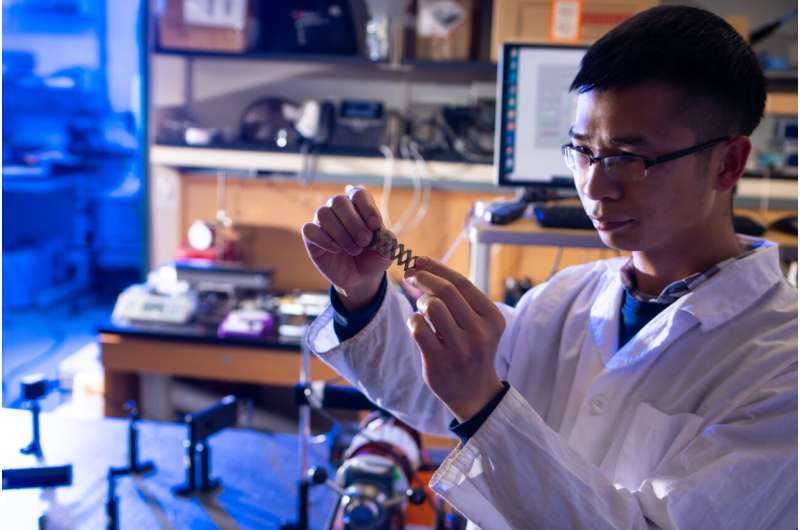

Yulong Huang, UB postdoctoral researcher in mechanical and aerospace engineering, holds a 3D-printed structure containing the magneto-ionic material used in a new study. The ability to print the material in varied shapes could facilitate different applications, scientists say. Credit: Douglas Levere / University at Buffalo

In addition to Ren, corresponding authors of the study include Yuguang C. Li, Ph.D., UB assistant professor of chemistry; Fei Yao, Ph.D., UB assistant professor of materials design and innovation; and Qimin Yan, Ph.D., Temple University assistant professor of physics. Yong Hu, a UB Ph.D. student in mechanical engineering, was the first author.

The team's magneto-ionic material is made from vanadium, chromium and cyanide, with an aqua ligand. The paper in PNAS describes the characteristics of the compound that make it ideal for use in rechargeable batteries, and outlines the techniques the scientists used for measuring the material's changing magnetism in a rechargeable lithium-ion battery.

More information: Yong Hu et al, Lithiating magneto-ionics in a rechargeable battery, Proceedings of the National Academy of Sciences (2022). DOI: 10.1073/pnas.2122866119

Journal information: Proceedings of the National Academy of Sciences

Provided by University at Buffalo