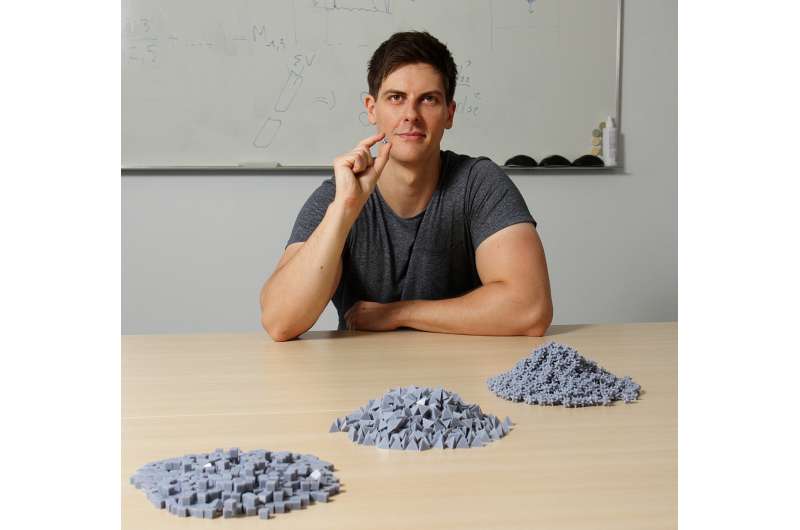

Robert Hesse shows the 3D-printed non-spherical particles he used to validate the simulation models in the project. Credit: TUK, Koziel

Round particles and their properties are easy to describe mathematically. But the less round or spherical the shape, the harder it becomes to make predictions about their behavior. In his doctoral thesis at the Technical University of Kaiserslautern (TUK), Robert Hesse has trained a neural network to automatically determine the packing density and flowability of non-spherical particles.

Few particles in nature or in industrial production are exactly round; instead, there are a multitude of variants and shape characteristics. This is exactly what makes it so complicated to describe non-spherical particles and optimize their handling based on the description. For example, the rounder a tablet is, the less likely it is to snag on other tablets in the filling process. A flat cylindrical shape can already be optimized by slight rounding when it comes to packing density.

But how can all the properties that determine flowability and packing density be quickly recorded in order to derive decisions on the choice of a shape? What previously required simplified calculations of individual mathematical parameters or mold components can be derived automatically by a trained artificial intelligence—in this case a so-called "Deep Convolutional Neural Network"—using a 3D model.

"Using simulations in which only the shape of the particles varied, I created a comprehensive experimental data set and used it to train the neural network," reports Hesse, a research associate at the Department of Mechanical Process Engineering. "Standardized experiments with 3D-printed particles allowed the simulation methodology to be validated in the test phase—that is, to match how accurately the simulation can represent real particles."

The trained neural network now filters out salient features such as curves, corners, edges, etc. from any three-dimensional point cloud representing the entire shape. Using this information, it can analyze flowability and random packing density. "This is useful, for example, for optimizing the shape of pharmaceutical products in terms of minimum machine dimensions and package sizes," the researcher says.

Provided by Technische Universität Kaiserslautern