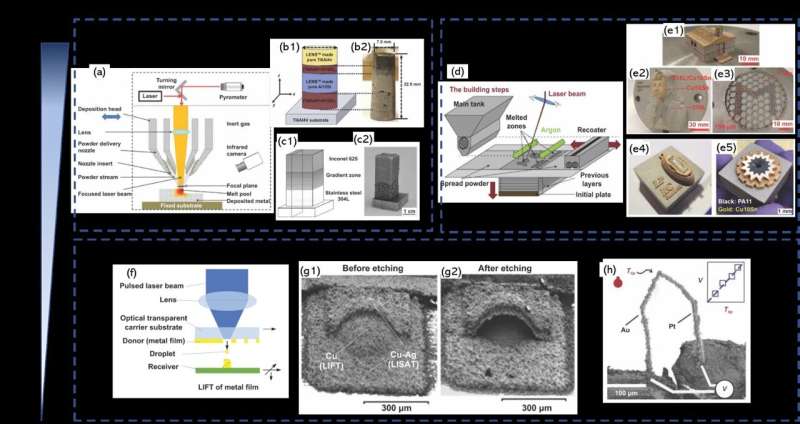

Laser metal deposition (LMD), laser-based powder bed fusion (L-PBF) and laser-induced forward transfer (LIFT) have the capability to fabricate multiple metallic materials. The scale of samples for each technology is presented. The dimensions of LMD and LPBF printed samples can be as large as meter-scale. Meanwhile, the LIFT process can produce micrometer-scale components. Credit: Chao Wei et al

Compared with general additive manufacturing (AM) methods, Multi-material additive manufacturing (MMAM) enables a higher level of design freedom, such as integrating materials, structure and function to achieve tailorable functionalities (e.g., local wear resistance, high thermal conductivity, thermal insulation, and chemical corrosion resistance, etc.). However, MMAM of metallic materials is a recent research activity still in its embryonic stage. Notably, there has been so far no comprehensive review about metallic MMAM covering both macroscale fabrication to microscale fabrication.

A study in the International Journal of Extreme Manufacturing summarized the recent progress on laser-based multi-material additive manufacturing (MMAM) technologies, including laser powder bed fusion (LPBF), laser-based directed energy deposition (L-DED) and laser-induced forward transfer (LIFT), for macro-and micro-scale fabrication of multiple metallic materials.

The use of LPBF method and L-DED method to produce large multi-material parts has become a reality because of various new inventions of the dissimilar powder materials deposition mechanisms. The potential applications of these technologies are to fabricate functionally integrated components widely used in aerospace, marine, nuclear power, and medical industries.

As for micro-AM of multiple metallic objects, solid LIFT and fluid LIFT are the technologies mainly employed currently, because their material transfer mechanism, jetting metallic droplets from one donor plate to the building substrate, is very suitable for printing dissimilar materials together. There is no contact between the donor and the printed object during material depositing, hence the dissimilar raw material cross-contamination problem is avoided. The potential applications of micro-scale metallic AM technologies include: 3D micro-scale metallic structures, energy storage components, electronic components, biomolecules, biochemical sensors and cells, and even directly transferring functionally devices to the surface of other parts.

Laser-based MMAM technologies are still at their early stage, hence many scientific and technical challenges are waiting for solutions. The research team led by Prof Lin LI, from the University of Manchester, reported the state of the art of this field and pointed out both the urgent challenges and relevant high-value future research topics.

The equipment of MMAM technologies may be significantly different from the standard single-material AM processes due to the dissimilar material dispensing challenge (i.e., how to deposit the right material at the desired region in the spatial space). This work summarizes the material delivery method, joining of dissimilar materials, processing parameters and printed MMAM components' performance. The material delivery methods for each MMAM method are introduced and their merits are compared. Three typical dissimilar material joining methods are presented. The material composition of MMAM-printed functional gradient materials (FGMs) is constantly changing. Therefore, the optimized laser parameters for each material composition are essential to achieving good printing quality.

The laser parameter-induced influence on the MMAM-printed microstructure may also be significantly different from the conventional AM technology, such as for the phase transition, the formation of intermetallic compounds and the final mechanical properties. The current commercial 3D design software, phase transition prediction software and simulation & modeling software are usually designed for single-material processing and lack the thermodynamic databases required for multi-materials processing.

All above issues are the knowledge gaps that need to be filled to push the MMAM technologies from the laboratory investigation to the actual industrial application. Professor Chao Wei explained that "we need to choose the appropriate technology based on the requirement of the final component. Before that, understanding the existing methods is very important for the user to choose the manufacturing method."

As an emerging field, MMAM has significant advantages in endowing different properties within one component via combining different materials, which is a new degree of freedom to the AM components. Among the potential fields, Professor Wei said that "laser-based MMAM has great potential in the metal functional 3D structures, energy storage components and print tissues and organs in the biomedical fields."

One of the lead researchers, Professor Lin Li commented that "laser-based MMAM technologies have obvious advantages in simplifying the manufacturing process, increasing design freedom, and reducing the time and costs of prototype manufacturing, compared with conventional manufacturing methods. Our work only opens the door to this new research paradise. We hope that more researchers can enter this field and jointly promote the development of MMAM technologies."

The future MMAM research is obviously multidisciplinary, involving mechanical engineering, manufacturing engineering, materials science, electronics, photonics, biology and other disciplines. Integrating complex hybrid manufacturing systems, establishing new laws for MMAM designing and manufacturing, high-throughout optimizing processing parameters, artificial intelligence-based quality monitoring and controlling, and assessing the long-term reliability of printed parts need to be further studied. However, we believe that under the guidance of the actual industrial application demand and through the collaborative research of the academic community, these problems will eventually be solved.

More information: Chao Wei et al, An overview of laser-based multiple metallic material additive manufacturing: from macro- to micro-scales, International Journal of Extreme Manufacturing (2020). DOI: 10.1088/2631-7990/abce04

Provided by International Journal of Extreme Manufacturing