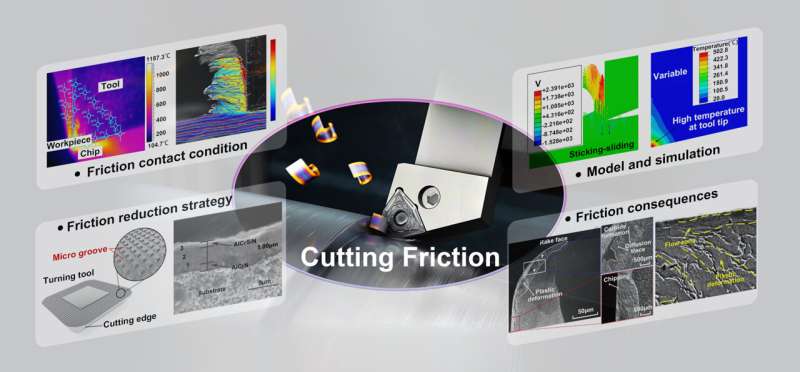

Cutting friction was very extreme due to high temperature, large strain/strain rates, sticking-sliding contact states, and diverse cutting conditions. Several theoretical models and the application of simulation technology were proposed. The factors that affect friction behaviors and the tool friction reduction strategy are summarized, including material matching, cutting parameters, lubrication/cooling conditions, micro/nano surface textures, and tool coatings. The consequences of the cutting friction phenomena, including tool wear patterns, tool life, chip formation, and the machined surface were analyzed. Credit: Xiaoliang Liang, Zhanqiang Liu, Bing Wang, Chunjin Wang and Chi Fai Cheung.

Material removal in the cutting process is regarded as a friction system with multiple input and output variables. The complexity of the cutting friction system is caused by the extreme conditions existing on the tool-chip and tool-workpiece interfaces. Knowledge of cutting friction behaviors are crucial for researchers and industrial manufacturing engineers when designing cutting processes that reduce tool wear and improve surface quality. Research on the theoretical models, simulation applications, influencing factors, and consequences of cutting friction behaviors should guide the manufacturing process.

Teams led by researchers from Shandong University and the Hong Kong Polytechnic University reviewed the state of the art of research on friction behaviors in cutting procedures and future perspectives and published their findings in the International Journal of Extreme Manufacturing.

Tool wear and surface quality deterioration further limit the application of high-speed machining technology. To solve the bottleneck of high-quality and high-efficiency cutting technology, the scholars have researched friction behaviors in the cutting process.

This research team systematically reviewed the phenomenon of cutting friction in local contact with extreme loads, the theoretical model of cutting interface friction and the application of simulation technology, the key factors affecting cutting friction behavior and anti-friction strategies, and the effect of cutting friction on machining results.

One of the lead researchers, Prof. Zhanqiang Liu, a head of the academic committee, the School of Mechanical Engineering, Shandong University, commented, "The critical distinction between cutting and other metal-forming processes is the fracture process of material separation into the workpiece and chip, where the contact interface is accompanied by intense friction resulting from shear, extrusion, and deformation. During metal cutting, more than 20% of the total energy is used to overcome the friction at the tool-chip and tool-workpiece contact interfaces. "

Prof. Chi Fai Cheung, a head of the State Key Laboratory of Ultra-precision Machining Technology at the Hong Kong Polytechnic University stated, "The cutting friction behaviors have essential influences on the cutting process. With the rapid development of manufacturing technology in the direction of 'high precision, high efficiency, intelligence, compound, and green,' the basic theory and application technology of cutting friction have advanced significantly."

Prof. Bing Wang from Shandong University pointed out the tool wear process under the influences of thermo-mechanical coupling and other multi-physical fields and chemical effects is analyzed based on the research on the tribological characteristics of the cutting process of difficult-to-machine materials. The development of a high-quality and high-efficiency cutting technology was promoted by improving the predictability of tool wear status and tool life.

First author Dr. Xiaoliang Liang from the Hong Kong Polytechnic University said, "Our research on cutting friction behavior will be primarily driven by the manufacturing industry's demand for process and machined surface metrics. By studying the influence of cutting friction on the integrity of the machined surface and avoiding using a single surface integrity parameter to judge the tool life, a tool life criterion based on multi-objective optimization of surface integrity is established. In addition, a material processing technology-surface integrity-service performance relationship model should be considered."

Prof. Zhanqiang Liu pointed out, "Future work should focus on the study of extreme cutting friction mechanisms, such as ultra-high-speed cutting, ultra-precision cutting, heavy-duty cutting, ultra-low temperature cooling cutting, and multi-energy field-assisted cutting. The advanced friction data acquisition system converts traditional friction parameter input into contact speed, load condition, lubrication state, and tool material/coating under actual cutting conditions."

More information: Xiaoliang Liang et al, Friction behaviors in the metal cutting process: state of the art and future perspectives, International Journal of Extreme Manufacturing (2022). DOI: 10.1088/2631-7990/ac9e27

Provided by International Journal of Extreme Manufacturing