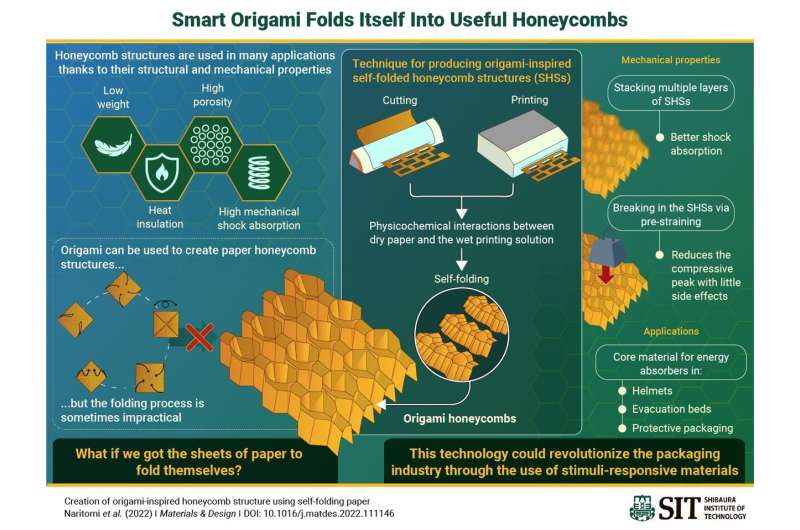

In a recently published study, researchers from SIT, Japan, developed a cost-effective method of making paper sheets that fold themselves without any human intervention into honeycomb structures with superb structural and mechanical properties. Credit: Hiroki Shigemune from SIT, Japan

Origami, the act of folding flat sheets of material into complex 3D shapes, has transcended its original artistic and ceremonial roots and entered the realm of engineering. Thanks to their low cost and simple fabrication process, origami-based structures and materials have found applications across varied fields, including biomedicine, packaging, spacecrafts, and agriculture.

One of the most difficult aspects of using origami in practical applications is finding a convenient, cost-effective way to fold the sheets of material into the desired shape. The folding process can be particularly challenging for origami structures of either very small or very large size. Accordingly, scientists have been actively trying to come up with new ways to create self-folding origami structures that are compatible with their target application.

In a recent study, a research team from Shibaura Institute of Technology (SIT), Japan, demonstrated a promising method to easily manufacture self-folding origami honeycomb structures (SHSs). As explained in their paper published in Materials & Design, honeycomb structures make for great protective packaging materials due to their many attractive properties, including low weight, high porosity, heat insulation, and excellent mechanical shock absorption.

Motivated by this, the team developed a low-cost process to produce SHSs using nothing but a paper cutter and a standard inkjet printer. The study was led by Associate Professor Hiroki Shigemune and co-authored by Professor Naoki Hosoya and master's student Daichi Naritomi, all from SIT, as well as Professor Shingo Maeda from Tokyo Institute of Technology. The paper was made available online on September 16, 2022, and will be published in Volume 223 of the journal in November 2022.

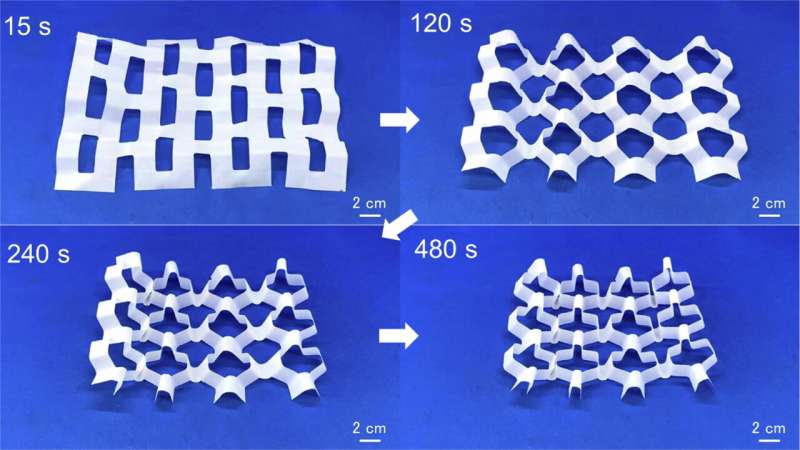

The key to this novel method to produce SHSs is to take advantage of the physicochemical interactions that occur between the paper and the printed solution. The researchers first cut out a grid of rectangles on a flat paper sheet and then use the inkjet printer to apply the printing solution in a carefully devised pattern; this results in the honeycomb structures folding themselves in a matter of minutes.

The team focused on analyzing how various parameters of the cutting and printing patterns affected the structural and mechanical properties of the final product. After finding a set of optimal parameters, they tested two additional ways to further improve the mechanical performance of the SHSs. The first was stacking multiple honeycomb layers on top of each other, which greatly increased the cushioning performance of the final structure with negligible changes to its height. The second was pre-straining the honeycomb structure, which is essentially applying a strong compressive force once before the material is put to use.

By "breaking in" the material in this way, they eliminate a compressive force peak that occurs the first time a brand new SHSs is compressed, which could damage the protected object.

The proposed approach to create SHSs could see use across a vast range of applications, as Associate Professor Shigemune explains via a few examples: "Our technique could be used to create tailor-made cushioning materials at farm sites based on the type and harvesting period of fruits and vegetables. Alternatively, it could be used to produce evacuation equipment, such as helmets and beds, using SHSs as a core material."

As a low-cost option for packaging that is easy to mass produce and configure, self-folding origami structures represent a promising approach to protect fragile goods, such as agricultural produce or electronic equipment. Credit: Hiroki Shigemune from SIT, Japan

Another notable advantage of SHSs is that they are made purely out of paper, a material that takes little space to store and that can be processed quickly at low cost. It's also worth noting that SHSs should be considered green technology since they are made from nontoxic materials using very little energy. "Our technology contributes to sustainable development goals because it allows us to protect fragile components and vegetables, which translates to fewer losses," remarks Associate Professor Shigemune.

More information: Daichi Naritomi et al, Creation of origami-inspired honeycomb structure using self-folding paper, Materials & Design (2022). DOI: 10.1016/j.matdes.2022.111146

Provided by Shibaura Institute of Technology