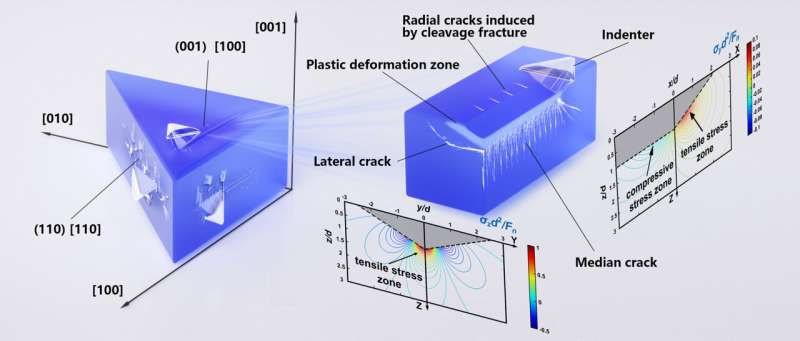

Schematic diagram of surface/subsurface damage and material removal behavior of MgF2 single crystal induced by nanoscratch, and distribution of normalized stress field in YOZ and XOZ planes when brittle removal occurred in scratch process. Median cracks induced by tensile stress initiated and propagated at the front of the indenter during loading process, and lateral cracks induced by tensile stress initiated and propagated on the subsurface during the unloading process. The tensile stress during unloading might cause cleavage fracture of the MgF2 single crystal, inducing the initiation of radial cracks on the workpiece surface. Credit: International Journal of Extreme Manufacturing (2022). DOI: 10.1088/2631-7990/ac9eed

The research team, led by A/Prof. Chen Li from the State Key Laboratory of Robotics and System (HIT), Harbin Institute of Technology, China, has shown the anisotropy dependence of the damage evolution and removal behaviors involved in ultra-precision machining of MgF2 crystals in terms of stress field, slip deformation and cleavage fracture.

Published in the International Journal of Extreme Manufacturing, their findings not only provide a theoretical foundation for achieving the high-efficiency and low-damage processing of anisotropic single crystals, but also are of great significance to achieving the large-scale industrial production and application of anisotropic crystal components, such as infrared windows, resonators and chip wafers.

Anisotropy considerably affected the damage evolution in the machining of MgF2 single crystals. The scratch of the (001) crystal plane along the [100] crystal-orientation was found to be the most conducive to achieving plastic machining of MgF2 single crystals.

A stress field model induced by the scratch was developed by considering the anisotropy, which indicated that median cracks induced by the tensile stress initiated and propagated at the front of the indenter during the loading process, and lateral cracks induced by tensile stress initiated and propagated on the subsurface during the unloading process. In addition, surface radial cracks induced by the tensile stress were easily generated during the unloading process.

The plastic deformation parameter indicated that the more the slip systems were activated, the more easily the plastic deformation occurred. The cleavage fracture parameter indicated that the cracks propagated along the activated cleavage planes, and the brittle chunk removal was owing to the subsurface cleavage cracks propagating to the crystal surface. The theoretical results agreed well with the experimental results.

One of the lead researchers, Prof. Feihu Zhang, commented, "MgF2 crystals are typical hard-to-machine materials owing to their distinct mechanical anisotropy and high brittleness, which will seriously decrease the service accuracy and life of the crystal components. The recent investigations of the machining of MgF2 single crystals focused on the mechanical properties and cutting process tests at a microscale. The damage evolution and material removal mechanisms induced by ultra-precision machining were not well revealed."

Fewer investigations systematically analyzed the anisotropy dependence of the material deformation and removal behaviors at a nanoscale involved in the ultra-precision machining of MgF2 single crystals. First author A/Prof. Dr. Chen Li explained, "In our work the damage evolution and removal mechanisms of MgF2 crystals induced by the nanoscratch were revealed in terms of stress field, slip deformation and cleavage fracture."

Prof. Yanquan Geng pointed that this work obtained the optimum orientation during ultra-precision machining of MgF2 crystals based on both theoretical analysis and experimental investigation, which was of great significance to achieve the crack-free plastic machining of anisotropic brittle materials.

Dr. Chen Li said, "This is a milestone achievement and it is only the beginning—we are already looking to use this technique to reveal other brittle crystals with distinct anisotropy, and achieve the large-scale industrial production and application of anisotropic crystal components, such as infrared windows, resonators and chip wafers."

More information: Chen Li et al, Understand anisotropy dependence of damage evolution and material removal during nanoscratch of MgF2 single crystals, International Journal of Extreme Manufacturing (2022). DOI: 10.1088/2631-7990/ac9eed

Provided by International Journal of Extreme Manufacturing