Credit: Kiyokawa et al.

As robots become increasingly advanced, they are being trained to complete a wide variety of tasks. Some roboticists have been specifically exploring the potential of robotic systems that can assembly items without much human supervision, as this could significantly speed up industrial and production processes.

Researchers at Nara Institute of Science and Technology (NAIST) have recently created a soft jig that could be used to improve the performance of general-purpose assembly robots. This jig, introduced in a paper presented at the IEEE International Conference on Robotics in and Automation (ICRA), is based on the universal jamming gripper, a system created by roboticists at the University of Chicago Cornell University and iRobot.

"Our soft jig is inspired by a soft robotic gripper called jamming gripper that has been getting a lot of attention from robotics researchers," Takuya Kiyokawa, one of the researchers who carried out the study, told TechXplore. "The main objective of our study was to improve the flexibility of fixtures for the assembly parts handled by the gripper."

Ultimately, Kiyokawa and his colleagues would like to develop a generic robotic assembly system that could speed up low-volume production processes. The soft jig they created could be a first step in this direction, as they found that it could improve the previously developed robotic gripper's ability to assemble different items.

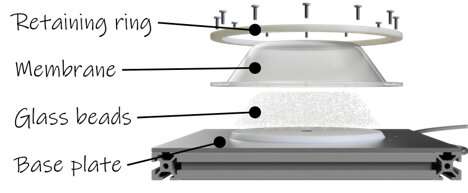

"A key advantage of our soft jig is its hardware structure, because the silicone membrane including the glass beads enables the jamming transition and gives the flexibility as the fixture for complicated assembly parts," Kiyokawa explained.

The soft jig developed by the researchers is essentially a bag full of glass beads, which is covered with a malleable silicone membrane. The glass beads allow it to perform optimal jamming transitions, while the silicone membrane improves friction and flexibility, allowing the jig to grip individual parts better and keep them still.

In their paper, Kiyokawa and his colleagues also outline a method that could be used to configure their soft jig's ability to keep parts of the items handled by the gripper fixed. To effectively configure the jog, this method considers a series of factors, including contact relations, reachable directions, and the center of gravity of the parts attached to the jig.

Credit: Kiyokawa et al.

"Our study demonstrates the possibility of holding fixed hardware parts even when applying external forces to them," Kiyokawa said. "If our future studies go well, we believe that the soft jig will break through the flexibility limitation of general-purpose metal jigs."

The researchers evaluated the soft jig they developed in a series of tests, specifically assessing its fixing performance and versatility (i.e., its ability to handle parts of different shapes and sizes). The results achieved in these tests were highly promising, suggesting that the jig could eventually be used to create robots that can complete assembly tasks more efficiently.

"We have already improved the soft jig, so that the jig system can estimate the parts poses fixed on the jig," Kiyokawa said. "The parts poses can be estimated by tracking the markers attached on inner surface on the jig from cameras placed under it. Now, we plan to develop motion planning algorithms to achieve flexible but 'precise' assembly operations that require high assembling accuracy, utilizing our soft jig."

More information: Soft-jig-driven assembly operations. IEEE International Conference on Robotics and Automation (ICRA)(2021). DOI: 10.1109/ICRA48506.2021.9562008

Tatsuya Sakuma et al, Soft-jig: A flexible sensing jig for simultaneously fixing and estimating orientation of assembly parts. arXiv:2109.07087v2 [cs.RO], arxiv.org/abs/2109.07087

© 2021 Science X Network