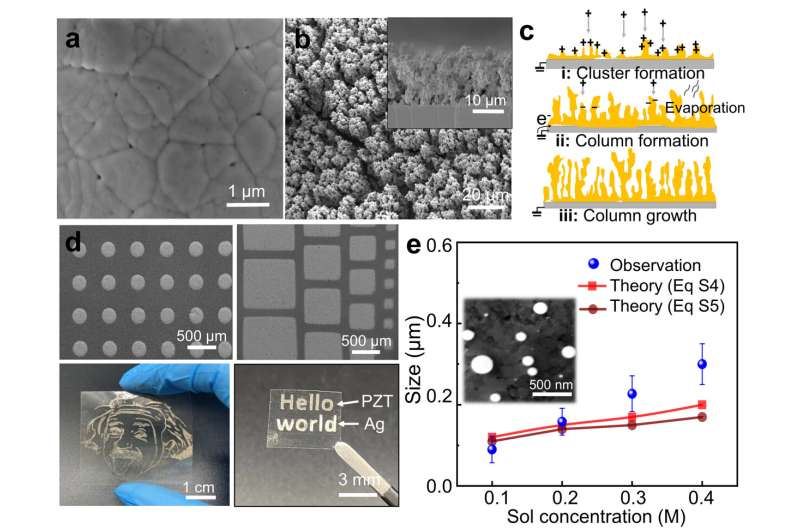

Fabrication of piezoelectric films, micro-patterns and nanoparticles. Credit: adapted from Nature Communications (2023). DOI: 10.1038/s41467-023-42159-9

Amidst the ongoing surge in demand for microelectromechanical systems (MEMS), wearable/implantable electronics, miniaturized portable devices and the Internet of Things, the pursuit of piezoelectric materials has become a priority interest for many because they intrinsically couple mechanical and electrical energy.

Nanoparticles, films and patterns are three critical piezoelectric elements with widespread applications in sensing, actuation, catalysis and energy harvesting. Mass production of these elements remains a challenge, as exerting control of these structures and feature sizes on various substrates is a complicated process.

Inspired from nature

Thunderstorms are a discharge phenomenon in the atmosphere that occurs in cumulonimbus clouds. During formation of these clouds, they will carry charges and the surface of the Earth will generate anisotropic charges due to electrostatic induction.

When the electric field intensity of a thunderstorm reaches sufficient strength (generally greater than 25–30 KV/cm), internal discharge in the thunderstorm or strong discharge between thunderstorms will occur. Streams of droplets from the tips of raindrops in a thunderstorm cloud will be ejected. Our team has been inspired by this natural phenomenon, and we have been thinking about the construction of high-throughput 3D microprinting machines oriented for industrial demands.

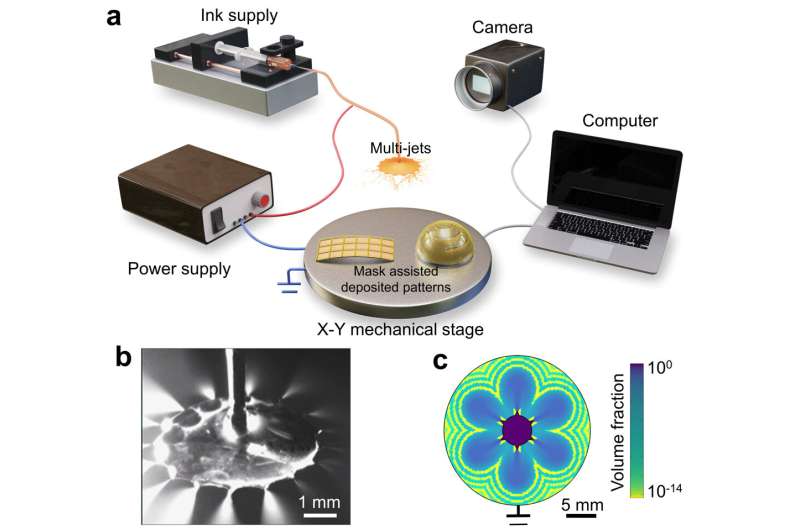

Electrostatic disc microprinting process showing the formation of multi-jets. Credit: Nature Communications (2023). DOI: 10.1038/s41467-023-42159-9

We constructed a 3D microprinting mechanism using a spiny disc connected to a needle and a power supply. Once we create an electrostatic field powerful enough to serve as a propellant, streams of ink could be cone-jetted onto a platform forming micropatterns, similar to the way streams of charged droplets are ejected from the tips of raindrops in a thunderstorm.

The work is published in the journal Nature Communications.

The microprinter, built at a lower cost compared with other printers on the market, uses an electrostatic field to propel streams of ink onto a platform, allowing for efficient manipulation of thin film patterns and enhanced printing speed to address the challenge of mass production and control of structures and feature sizes.

Through the efforts of our team, the manufacturing speed has been enhanced by a factor of 100, allowing for efficient manipulation of thin film patterns similar to semiconductor lithography. For instance, a 10 μm-thick lead zirconate titanate (PZT) film on a 4-inch Si wafer can be fabricated with minimal material wastage in just 10 minutes using the printer. This breakthrough technique is applicable in manufacturing piezoelectric components for microphones, clinical ultrasound probes and thin-film solar panels, with the expectation of reducing the production cost of related products.

Our microprinter also shows printing capability for a wide-ranging classes of materials such as dielectric ceramics, metal nanoparticles, insulating polymers and biological molecules. It boasts the fastest speed in existing techniques for piezoelectric, micrometer-thick films, and the films we produced demonstrate excellent piezoelectric properties compared to current ones on the market.

-

Schematic of electrostatic disc microprinter and multiplexed jetting/tiny droplets from the thin spiny disc. Credit: Nature Communications (2023). DOI: 10.1038/s41467-023-42159-9

-

Prof. Yang Zhengbao (middle), Postdoctoral Fellow Dr. Li Xuemu (Right) and Doctoral Student Zhang Zhuomin (left).

This new, affordable model of precision printing with features measurable at ~20 μm could bring benefits to many in the scientific world and lead to many breakthroughs that were previously thought impossible.

The novel microprinter represents a significant step toward ultrafast, large-area additive micromanufacturing of 3D objects with virtually any composition and adjusted microstructure and functionality.

Now our team is focused on integrating the printer with roll-to-roll substrate receiving systems to enable potential commercial applications. Additionally, we are actively seeking collaborations with commercial partners to enhance its market presence further.

This story is part of Science X Dialog, where researchers can report findings from their published research articles. Visit this page for information about ScienceX Dialog and how to participate.

More information: Xuemu Li et al, Fast and versatile electrostatic disc microprinting for piezoelectric elements, Nature Communications (2023). DOI: 10.1038/s41467-023-42159-9

Li Xuemu is now a Postdoc fellow in Mechanical Engineering at City University of Hong Kong (CityU), and a visiting scholar at the Hong Kong University of Science and Technology (HKUST). His research interests include advanced manufacturing, piezoelectric/ferroelectric, biomaterials, flexible electronics and soft robotics, biomedical engineering, MEMS, sensors, energy harvesting, and ultrasonic transducers.