Credit: CSEM

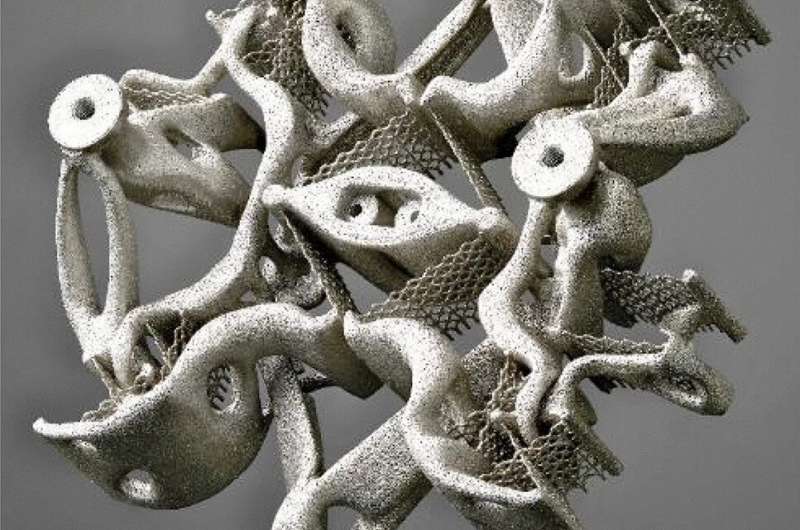

It might look like some bizarre alien artwork but this is actually a frictionless gear mechanism, 3D-printed all in one in high-performance stainless steel, designed to enable the precise rotation of items such as satellite thrusters, sensors, telescope lenses or mirrors.

Standard moving parts in space involve friction, and therefore require some kind of lubrication that can potentially lead to unwanted contamination of delicate systems, while also inducing ongoing wear and tear.

By contrast, this is an example of a "compliant mechanism" that transmit force through bending, or "elastic deformation," such as bag fasteners or bows and arrows. Incorporating 24 bendable blades, of which 16 are interlocking, the design serves to reduce the turning force induced upon it by a factor of 10, to allow very fine control of rotary motion.

This Compliant Rotation Reduction Mechanism was designed by CSEM in Switzerland, with Swiss company 3D Precision SA undertaking the 3D printing while its performance testing was undertaken by Almatech SA, as part of an ESA Technology Development Element activity.

Credit: CSEMtechnologies

Provided by European Space Agency