Plasma Lithium Mineral Carnobation Device. Credit: Korea Institute of Fusion Energy (KFE)

Recent research suggests an improved method for extracting lithium by applying plasma technology. Researchers from the Korea Institute of Fusion Energy (KFE) have successfully increased the lithium extraction rate by three times compared to pre-existing methods by applying CO2 microwave plasma technology.

The most common method of extracting lithium is mixing sodium carbonate (Na2CO3) to saltwater that contains lithium and extracting lithium carbonate (Li2CO3)—which is a mixture of lithium and carbon dioxide. The downside to this method is that it requires an additional process to separate the lithium carbonate from sodium impurities that blend together during the extraction process.

There exists an alternative method in which carbon dioxide gas is used instead of sodium carbonate. However, the issue with this method is that extraction rates are low in brine where lithium salt—a bond between lithium and chlorine- exists. Research is required to address this issue.

Dr. Ji Hun Kim and Dr. Jong Keun Yang of the KFE utilized carbon dioxide microwave plasma technology, which involves ionizing carbon dioxide into a plasma state to increase the rate of lithium extraction.

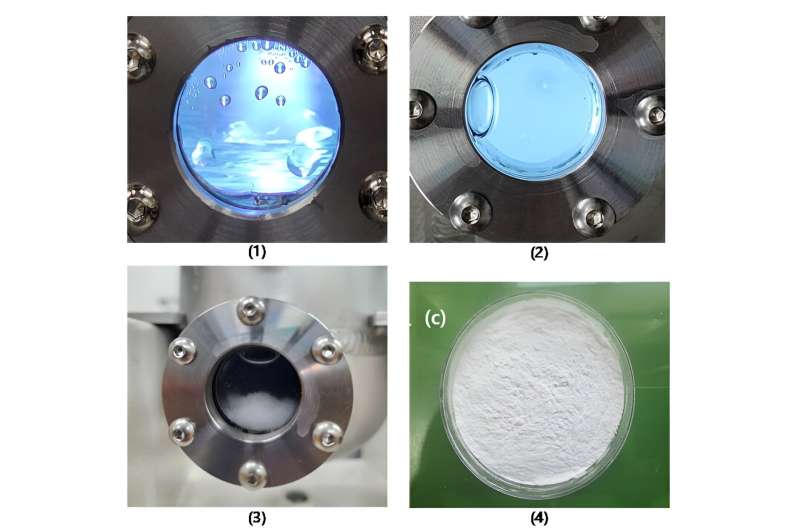

Plasma treatment of simulated brine that contains lithium. Credit: Korea Institute of Fusion Energy (KFE)

Researchers at KFE conducted experiments to compare carbon dioxide plasma lithium extraction and pre-existing methods of lithium extraction utilizing simulated brine. The research showed using plasma technology increased extraction rates by around three times.

While direct injections of carbon dioxide gas netted 10.3% lithium extraction rates, in experiments using carbon dioxide plasma, the lithium extraction rate reached 27.87%.

This is the first research to demonstrate an increase in lithium extraction rates by applying plasma technology to the lithium extraction process. The paper is published in Desalination.

Dr. Yang, who is the first author of the research paper, said, "It was possible to confirm the effects of the heat and ions, electrons, radicals etc. that are generated when carbon dioxide plasma forms on lithium extraction rates. We plan to expand research into plasma lithium extraction processes through additional research into carbon dioxide plasma reactions."

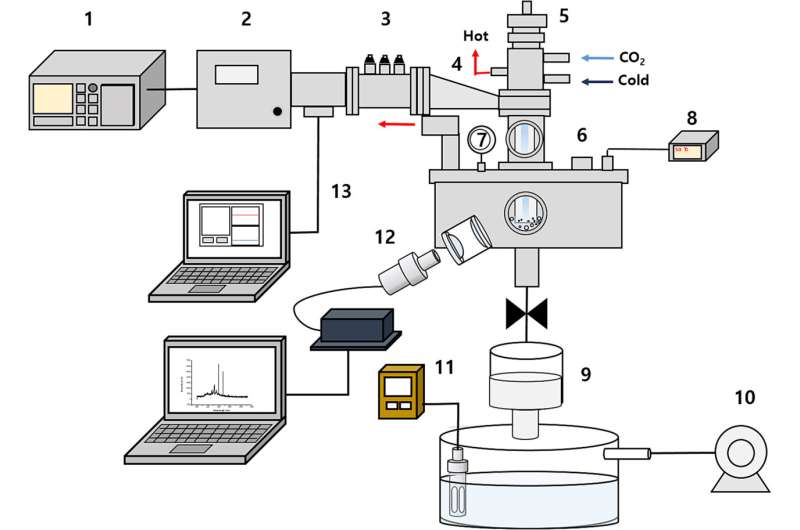

1. Schematic of the experimental setup: (1) microwave power supply, (2) magnetron, (3) three-stub tuner, (4) tapered waveguide, (5) holder with gas injector, (6) chamber, (7) pressure gauge, (8) thermocouple, (9) vacuum filter, (10) pump, (11) multi-parameter tester, (12) OES with collector, and (13) bipolar power meter.

Researchers are hopeful that lithium extraction processes using plasma can be a novel approach for developing technology that can more efficiently extract lithium from seawater with lower concentrations of lithium.

President Suk Jae Yoo of KFE said, "This research shows a new possible use for plasma technology, which has been used extensively in cutting-edge fields such as semiconductors."

"Lithium obtained from seawater is a crucial component of fusion energy generation, and we will continue to conduct research into both fusion energy development and fusion energy fuel acquisition."

More information: J.K. Yang et al, Novel approach for recovering lithium from simulated aqueous solutions using carbon dioxide microwave plasma, Desalination (2023). DOI: 10.1016/j.desal.2023.116978