February 11, 2015 weblog

Voltera team designs circuit board prototyping machine

Circuit boards made easily... where have you heard that before? You probably saw the news back in July about a Kickstarter campaign for Squink, a personal electronic-circuit factory for making circuit prototyping as easy and seamless as possible. The team behind Squink, BotFactory, had turned to crowdfunding, and their website's home page said, instead of waiting days for a printed circuit board, their printer can print conductive traces in minutes from Gerber files you are already making and they can print from other image formats too. "Our goal is to reduce the cost and time associated with electronics prototyping by providing technologies that allow such optimizations in an in-house environment. Our technologies enable our customers to shorten their development cycles, making them more productive an efficient, while allowing us to create a market around Agile Electronics Development." Using inkjet technology, Squink prints conductive ink on a surface to create the traces of the circuit. The site said, "Aimed at assembling SMD based circuits, Squink uses vacuum to pick components from a tray. Then it aligns them using computer vision, rotates them according to the "Centroid and Rotation" file created in your CAD tool and places them accurately."

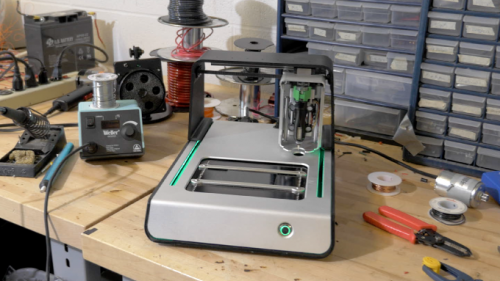

Now there is another group on the scene, Voltera, which has turned to Kickstarter to launch its creation. The Kickstarter campaign page said, "Print your circuit boards, dispense solder paste, and reflow! The Voltera V-One lets you go from concept to creation in minutes."

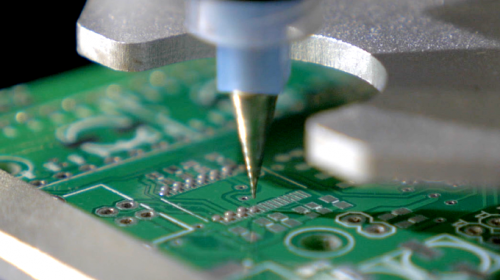

For those who need custom circuit boards, "Just press print," said Voltera cofounder Jesus Zozaya. James Pickard, cofounder, said: "We've all been there. We send a circuit design off to a factory, wait two weeks for delivery, only to find there's a mistake." The Voltera system was made to help hardware developers see their ideas come to life fast. Pickard said they use conductive and insulating ink to create two-layer circuit boards. Their software automatically detects trace intersections and lays down a mask where two traces overlap. Summing up the system's capability, the team said that "The Voltera V-One can create a prototype board right from your work bench. Gerber files go in; FR4 boards come out. The magic happens in the middle... the printer lays down a conductive ink to create the traces and an insulating ink as a mask between layers."

Katarina Ilic, another cofounder, said this was so much more than a prototyping tool. The printer can behave as a standalone solder paste dispenser. Once you add the components it will reflow the board as well. Toss out all those stencils, she said; you no longer need them.

The team decided last year to make the move to Shenzhen, China, and the move enabled them to nail down their supply chain and manufacturing processes. The team said they selected factories that they visited themselves to inspect the machinery, working conditions and quality of previous products built. "We also intend to spend a large amount of time at the factories while completing our first production run."

Barriers to hardware are falling all around us, they said, and "now it's about time the barriers around access to circuit boards fell too." What about pick and place? The team said, "A pick and place system is a very common feature request. Unfortunately, components will have to be added by hand for now. This is something that we would love to include and might be featured as an add-on later down the road."

They have gone to Kickstarter to raise funds to bring the product to reality and they impressively surpassed their $70,000 goal. With 29 days still to go, at the time of this writing, the total stands at $187,497.

According to the campaign page, each printer will come with a cartridge of conductive ink, insulating ink, solder paste, solder wire, blank boards in a few sizes, a sample pack of template boards, and cables and tools to get started.

Colin Jeffrey in Gizmag called out two interesting features of this Voltera V-One printing system, the two-layer circuit printing and the system's design to "automatically lay down solder paste on the pads to which components are attached and then solidify that paste by baking the board." He said, "This feature alone should save a hardware developer a bit of money by not having to pay to have boards populated with components, and many hours of downtime were the boards to be shipped out to have this work done."

The Voltera team is offering the V-One for $1,499 with shipment planned for January 2016.

More information: www.kickstarter.com/projects/v … -prototyping-machine

© 2015 Tech Xplore