Researchers develop MEMS accelerometer with higher sensitivity and improved noise reduction

A significant increase in the demand of accelerometers is expected as the market for consumer electronics, such as smartphones, and social infrastructure monitoring applications are expanding. Such miniaturized and mass-producible accelerometers are commonly developed by silicon MEMS technology where the fabrication process is well established.

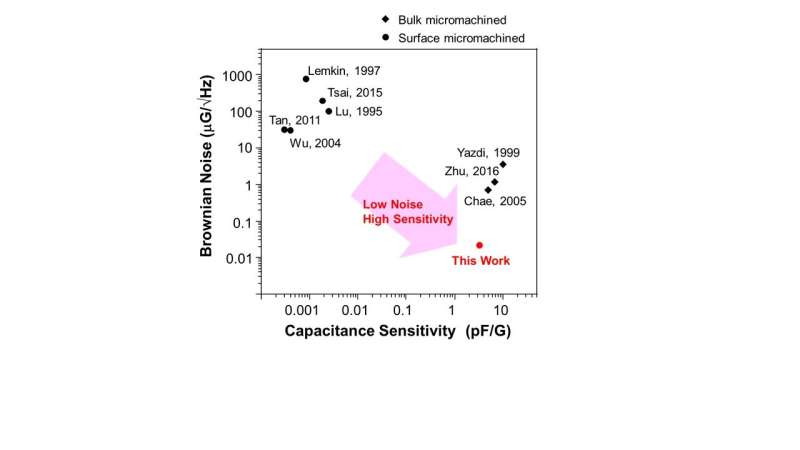

In the design of accelerometers, there is a trade-off between the size reduction and the noise reduction because the mechanical noise dominated by the Brownian noise is inversely proportional to the mass of the moving electrode called as proof mass. Moreover, capacitive accelerometers have sensitivity generally proportional to the accelerometer size, and thus there is also a trade-off between the size reduction and the sensitivity increase. Since high-resolution accelerometers require low noise and high sensitivity performances, it has been difficult for conventional silicon-based MEMS accelerometers to detect 1 μG level input acceleration.

Low noise and high sensitivity MEMS accelerometer

The research group consisting of researchers from Tokyo Tech and NTT Advanced Technology Corporation has previously proposed a method to downscale the proof mass size of MEMS accelerometers to less than one-tenth by using gold material. In this work, as an extension of this achievement, they have employed multi-layer metal structures to the proof mass and spring components, and developed a low-noise, high-sensitivity MEMS accelerometer.

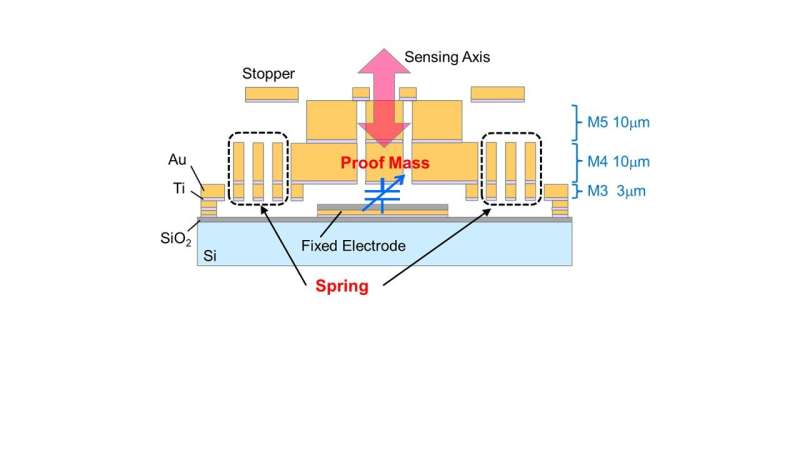

As shown in Fig. 1, they reduced the Brownian noise, which is inversely proportional to the proof mass, by increasing the mass per area with the use of multiple layers of gold for the proof mass structure.

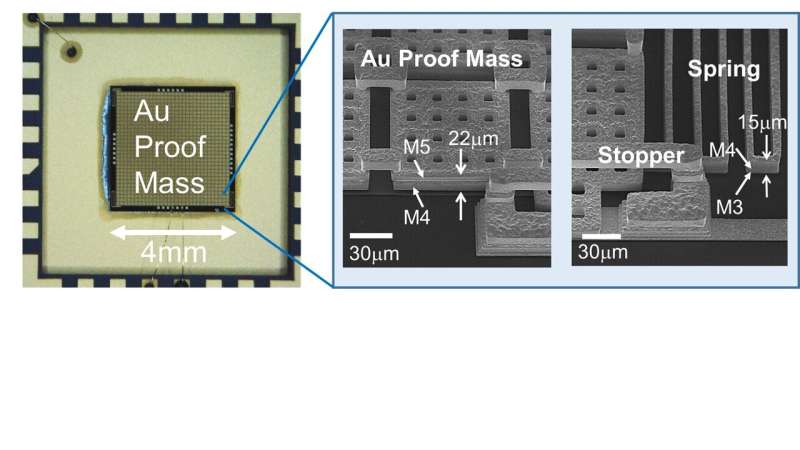

Furthermore, they utilized the whole area of the 4-mm-square chip by reducing the warpage of the proof mass, which enabled them to increase the capacitance sensitivity of the accelerometer. Figure 2 shows a chip photograph and scanning electron microscope images of the developed MEMS accelerometer.

The new accelerometer has sensitivity > 100 times over previous technology, and one-tenth less noise at the same size, as shown in Fig. 3. Accordingly, the researchers confirmed that the accelerometer can detect input acceleration as low as 1 μG. The fabrication process entailed semiconductor microfabrication processes and electroplating, and thus it could be possible to implement the developed MEMS structures on an integrated circuit chip. Therefore, the proposed technology would be useful to increase the resolution of miniaturized accelerometers for general purpose use.

The accelerometer could be applied to medical and healthcare technology, infrastructure monitoring, high-precision control of ultra-lightweight robots, mobile vehicle control, navigation systems in places where GPS cannot be used, and space environment measurement requiring ultra-low acceleration sensing.

More information: Sensors and Materials (2019). DOI: 10.18494/SAM.2019.2122