Pyroprocessing advances offer solution for fueling next-gen reactors

Modern pyroprocessing techniques promise to provide domestically sourced nuclear fuel at an affordable cost for next-generation reactors while drastically reducing the volume and toxicity of the remaining waste.

Around 5% of uranium in a light water reactor fuel rod is used to produce energy before the rods are removed from the reactor and placed into permanent storage, leaving the spent nuclear waste (SNF) to continue to decay at a relatively high toxicity rate for hundreds of thousands of years.

Work on recycling SNF—just under a third of the close to 400,000 tons produced globally has been reprocessed—has seen mixed results, producing potentially dangerous weapons-grade materials and at a cost that is significantly higher than mining more uranium.

Current worldwide reprocessing capacity is around just under 2,000 tons a year via plants in France, Britain, India and Russia.

Following the Russian invasion of Ukraine, securing a domestic fuel supply for U.S. nuclear reactors has become a priority and one line of research appears especially promising for next generation nuclear reactors currently in development.

Scientists at the U.S. Argonne National Laboratory began working on recycling fast reactor fuel in the early-sixties during the development of the Experimental Breeder Reactor-II (EBR-II) and later during the Integral Fast Reactor (IFR) program.

Argonne has extended work that began with the EBR-II, a fast neutron reactor, to develop pyrochemical processes for the recycling of oxide, carbide, and other advanced fuels.

The IFR, a liquid metal-cooled fast reactor, was later designed to produce energy and consume waste and while working on it researchers adopted a pyroprocess whereby an electrochemical reaction is used to separate the desired actinides from the undesired fission products for recycling into new fuel.

"Right now, our focus is moving pyroprocessing to a ready-to-deploy state," says Argonne's Pyroprocess Engineering section manager Krista Hawthorne.

Pyroprocessing and electrorefining

Pyroprocessing takes the hard ceramic oxide pellets retrieved from light water reactors—around 95% of which is still uranium and another 1% is long-lived radioactive elements actinides while the rest is unusable fission products—and converts the oxide constituents into metal.

That metal is then submerged into a vat of molten salt where, through electrorefining, an electric current selectively dissolves and redeposits uranium and other reusable elements which are then used to fabricate fuel that can be used by fast reactors.

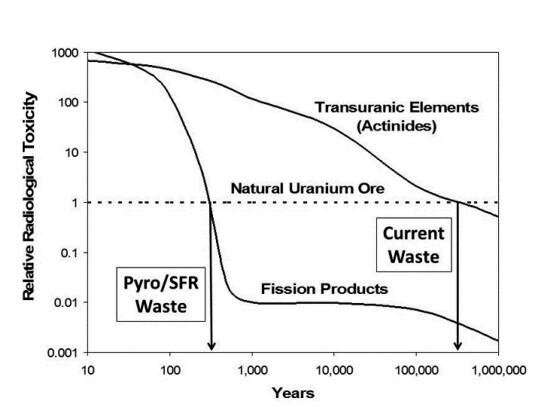

The 4% of the fuel that is unusable fission products still needs to be disposed of via permanent storage, though its radioactive toxicity reverts back to levels of naturally occurring uranium within a few hundred years, considerably less than the many thousands of years untreated SNF takes to revert because most of the long-lived isotopes have been recycled.

Relative radiological toxicity of used fuel constituents

Today, LWRs remain the standard design for nuclear reactors in the United States, for which raw uranium is a cheap and readily available fuel, but as fast reactors move closer to demonstrations and, by the end of the decade, commercial adoption, recycled fuel could be the norm.

Through extensive work on the economics of fuel recycling, Argonne's 2018 study, "Conceptual Design of a Pilot-Scale Pyroprocessing Facility," points to the viability of electrorefining as a practical solution to used fuel management and recycling for fast reactors.

In the research, a system designed to recycle 100 tons of fuel a year had total capital cost of $398 million including process equipment and support systems, estimated to cost $93 million, and the facility cost of $305 million.

Scaling up to 400 tons a year was estimated to run at a total capital cost of $911 million and annual operating cost of $90 million.

Since the study's release, Argonne has been improving on that design to take it to a commercially viable level using the latest technology.

"We're doing things such as integrating some of the next generation sensors that we've developed with process control to improve the efficiency. We're looking at improving the product collection method, lowering the cost of the processes, and we're also using techniques like machine learning," says Hawthorne.

Argonne is developing a digital twin of the electrorefiner which takes feedback from in-house developed monitoring sensors so the team is able to identify and respond to changing electrorefining conditions in real time.

"We're working along these lines to improve the efficiency and work toward industrialization of pyroprocessing," she says.

Oklo on board

Argonne's work, alongside microreactor developer Oklo, has caught the eye of the U.S. Department of Energy (DOE).

In August, U.S. Secretary of Energy Jennifer Granholm was given a tour of the company's experimental programs at Argonne by Oklo's founders CEO Jacob DeWitte and COO Caroline Cochran alongside Argonne Lab Director Paul Kearns.

The California-based developer has been awarded $11.5 million for three DOE competitive awards, channeled through the Technology Commercialization Fund (TFC), ARPA-E OPEN and ARPA-E ONWARDS, to develop advanced recycling technologies in partnership with Argonne.

Oklo was also awarded a grant via the Gateway for Accelerated Innovation in Nuclear (GAIN) for experimental liquid metal thermal hydraulic work at Argonne's new Mechanisms Engineering Test Loop (METL) facility.

The company, which has a site use permit from the DOE to build its first plant at Idaho National Laboratory (INL) and developed the first advanced fission combined license application, says it is on track to deploy its first commercial advanced reactor in the United States by 2025.

Next generation fast reactors, such as Oklo's Aurora, are supported by recycling used fuel and so offer a much-needed solution to closing the nuclear fuel cycle.

"Right now, waste is a huge liability and there's massive expenditures just to store it, so if someone were to pay us to take it off their hands, then that changes the economics. Even if it's free, it's still beneficial and economic," says COO Cochran.

The current concern over the cost of recycling is unfounded says Cochran, especially when fueling next generation fast reactors such as Oklo's Aurora, TerraPower's Natrium or molten salt reactors from Moltex and Elysium.

"There's no real fundamental reason why it should be so expensive. It's how you operate and regulate it. Fuel is our biggest single cost. If we can recycle it, then we can really achieve costs that are lower than anything on the grid today," she says.