November 11, 2022 report

Using an acoustic field to create a liquid metal conductive network inside a polymer

A team of researchers at the Korea Advanced Institute of Science and Technology, working with a colleague from Institute for Basic Science, both in the Republic of Korea, has found an easy way to create an electronic network inside a polymer. They used an acoustic field to connect liquid metal dots.

In their paper published in the journal Science, the group describes their technique and its possible uses. Ruirui Qiao and Shi-Yang Tang with the University of Queensland in Australia and the University of Birmingham, in the U.K., respectively, have published a Perspectives piece in the same journal outlining the work done by the team.

As portable devices have become mainstream, consumers have demanded more ease of use. One such call is for devices to be bendable and/or stretchable. It is believed such a change would make them fit more easily and naturally in pockets or purses—and they might be more comfortable in the hands, as well.

But making electronics bend or stretch is difficult because of the need for the circuits inside of them to also bend or stretch. This is challenging because bendable materials are not generally very good at conducting electricity. To address this problem, researchers have been looking to liquid metals.

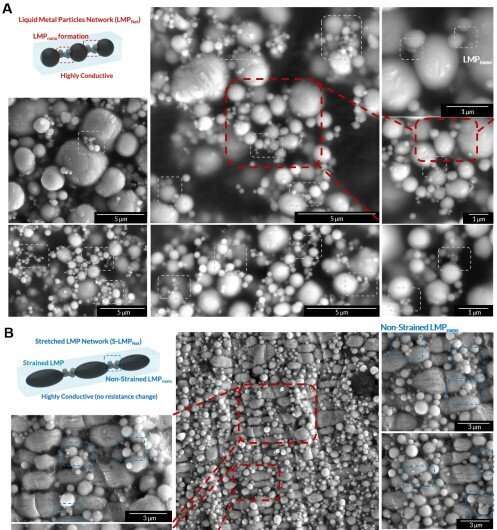

But that has presented problems, as well. Such metals typically react with oxygen, leading to the formation of an oxide skin, which is not conductive. In the new study, the researchers have found a way around this problem by using an acoustic field to create a bridge between liquid metal drops, which they then embedded in a polymer.

To create an electronic network using their technique, the researchers printed gallium-based liquid metal drops onto a surface while also applying an acoustic field. The vibrations from the field led to the formation of mini-drops forming a bridge between the larger drops, which allowed for the formation of a conductive network—and that allowed for the construction of a circuit. After the oxide skin formed, the liquid metal network was embedded inside of a bendable/stretchable polymer.

The result was a circuit that could be both bent and stretched. Testing showed that under strain, the individual beads of liquid metal stretched into oval shapes, allowing the circuit to continue conducting electricity.

More information: Wonbeom Lee et al, Universal assembly of liquid metal particles in polymers enables elastic printed circuit board, Science (2022). DOI: 10.1126/science.abo6631

Ruirui Qiao et al, Connecting liquid metals with sound, Science (2022). DOI: 10.1126/science.ade1813

© 2022 Science X Network