August 28, 2023 report

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Thin panels with inflatable pneumatic cells allow for bending flat structures in desired ways

A trio of materials scientists at Sorbonne Université has developed a new approach to creating types of thin panels that can be transformed into curved, 3D objects without resorting to wrinkling or cutting. In their study, reported in the journal Science, Tian Gao, José Bico, and Benoît Roman were inspired by plant morphing of leaves and petals to create a similar material for use in novel applications.

Prior engineering efforts have shown that it is possible to produce three-dimensional products by first starting with a flat piece of material. The reason for doing so is generally to allow for easier transport. Cardboard boxes take up much less room when flattened, for example. Robotics engineers have discovered the usefulness of such materials, as have scientists looking to send probes into space. However, creating such materials involves overcoming a major hurdle.

If you look at a flat map of Earth, for example, the continents appear distorted—this is because they have been flattened from a sphere. As the researchers note, attempts to forge three-dimensional products from a flat object typically requires wrinkling or cutting. They sought to overcome this problem with a new approach that started from their observations of how bulliform cells work in plants.

As an example, the leaves on corn plants can open and close depending on weather conditions—they do so by inflating bulliform cells using liquid pressure. To recreate this ability in a fabricated material, the team created what they describe as a shape-morphing structure based on Gaussian cells.

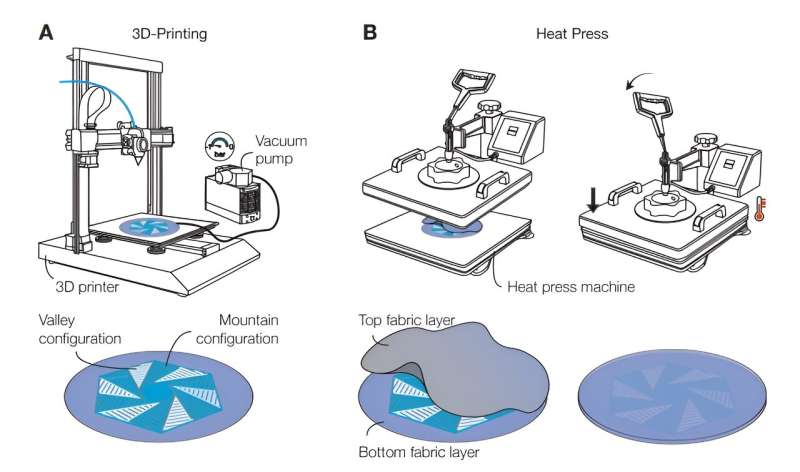

To create their model, the team 3D printed inflatable trapezoidal channels inside a flat panel. It was then sandwiched between two layers of airtight material. As air was pumped into the center part of the sandwich, the flat surfaces above and below were pushed and stretched into new shapes with unique Gaussian curvatures. By altering the size and shape of the trapezoids, the researchers were able to alter the 3D shapes that they could form.

More information: Tian Gao et al, Pneumatic cells toward absolute Gaussian morphing, Science (2023). DOI: 10.1126/science.adi2997

© 2023 Science X Network