This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Examining how cathode catalyst layer platinum loading affects the durability of proton exchange membrane fuel cells

Proton exchange membrane fuel cells (PEMFCs) hold promise as a replacement for fossil fueled engines in heavy-duty vehicles. Reducing the platinum content in catalysts is pivotal for scaling up in such applications. Yet, the degradation patterns of low platinum content catalysts remain poorly understood. A team of scientists conducted experiments to shed light on the degradation mechanisms associated with varying catalyst content, offering valuable insights.

Their work is published in the journal Industrial Chemistry & Materials.

In the field of heavy-duty vehicles, the PEMFC is a technology that will make it possible to replace the use of fossil fuels. However, there is an obstacle to the development of this technology, the use of platinum as a catalyst. Platinum is a rare and costly metal, impeding the commercialization of this technology, so it is necessary to reduce the amount used in the PEMFC electrodes.

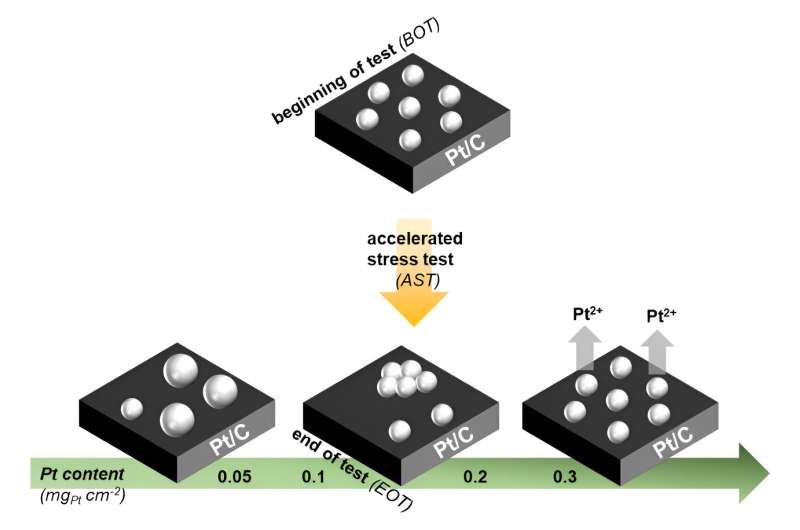

Four different platinum loadings (0.05 up to 0.3 mgPt cm-2) of the cathode catalyst layer were used to study the durability of PEMFC electrode-membrane assemblies. This study was based on a multiple stressor accelerated stress test targeting the membrane and the electrodes.

It was divided into two parts: first, the analysis of the membrane electrodes assemblies durability using a segmented cell during accelerated stress test, then physicochemical characterizations of the aged materials: transmission electron microscopy (TEM), grazing-incidence X-ray diffraction (GIXRD), cross-section scanning electron microscopy (SEM) and Raman spectroscopy.

In terms of initial performance, low-Pt loading (≤ 0.1 mgPt cm-2) cathodes exhibit lower oxygen reduction activity than "usual loading MEAs" (≥ 0.2 mgPt cm-2), being hindered by their low Pt content in the low current density (activation) region and adverse oxygen and proton transport resistance in the high current density (mass-transport) region.

However, it turned out that the mechanisms of Pt/C degradation are not depending on the cathode Pt loading for the chosen AST, though the initial degradations are faster for the lowest cathode Pt loadings, an evident drawback in terms of targeted lifetime.

The next step of this work is evidently to (i) mitigate the large mass-transport limitations that hinder low-loaded PEMFC cathodes and (ii) to enhance their durability.

More information: Ricardo Sgarbi et al, Does the platinum-loading in proton-exchange membrane fuel cell cathodes influence the durability of the membrane-electrode assembly?, Industrial Chemistry & Materials (2023). DOI: 10.1039/D3IM00059A