This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Understanding the dynamic behavior of rubber materials

Rubber-like materials, commonly used in dampeners, possess a unique property known as dynamic viscoelasticity, enabling them to convert mechanical energy from vibrations into heat while simultaneously exhibiting spring-like and flow-like behaviors. Customization of these materials is possible by blending them with compounds of specific molecular structures, depending on the dynamic viscosity requirements.

However, the underlying mechanisms behind the distinct mechanical properties of these materials remain unclear. A primary reason for this knowledge gap has been the absence of a comprehensive system capable of simultaneously measuring the mechanical properties and observing the microstructural dynamics of these materials.

While X-ray computed tomography (CT) has recently emerged as a promising option for a non-destructive inspection of the internal structure of materials down to nano-scale resolutions, it is not suited for observation under dynamic conditions.

Against this backdrop, a team of researchers, led by Associate Professor (tenure-track) Masami Matsubara from the School of Creative Science and Engineering at the Faculty of Engineering at Waseda University in Japan, has now developed an innovative system that can conduct dynamic mechanical analysis and dynamic micro X-ray CT imaging simultaneously.

Their study was published in the journal Mechanical Systems and Signal Processing.

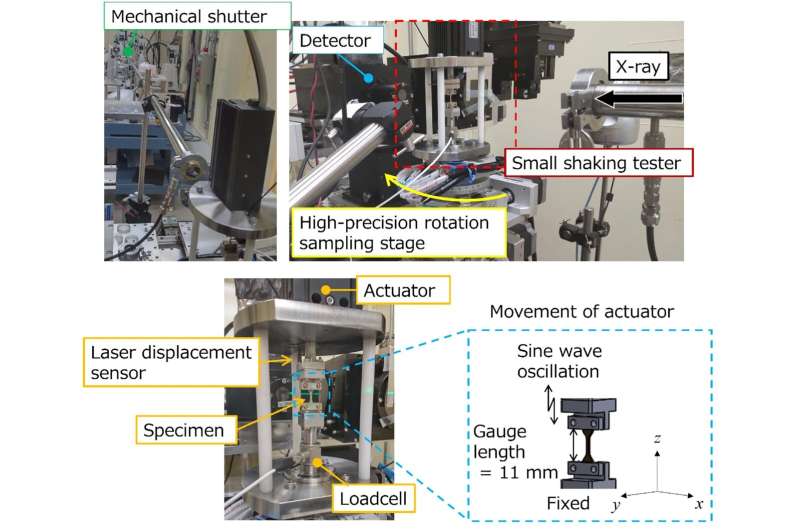

"By integrating X-ray CT imaging performed at the large synchrotron radiation facility Spring-8(BL20XU) and mechanical analysis under dynamic conditions, we can elucidate the relationship between a material's internal structure, its dynamic behavior, and its damping properties," explains Dr. Matsubara. At the core of this novel system is the dynamic micro X-ray CT and a specially designed compact shaker developed by the team capable of precisely adjusting vibration amplitude and frequency.

The team utilized this innovative system to investigate the distinctions between styrene-butadiene rubber (SBR) and natural rubber (NR) and explore how the shape and size of ZnO particles influence the dynamic behavior of SBR composites.

The researchers conducted dynamic micro X-ray CT scans on these materials, rotating them during imaging while subjecting them to the shaker's vibrations. They then developed histograms of local strain amplitudes using the local strains extracted from the 3D reconstructed images of the materials' internal structures. These histograms, in conjunction with the materials' loss factor, a measure of the inherent damping of a material, were analyzed to understand their dynamic behavior.

When comparing materials SBR and NR, which have significantly different loss factors, the team found no discernible differences between their local strain amplitude histograms. However, the histograms displayed wider strain distributions in the presence of composite particles like ZnO. This suggests that strain within these materials is non-uniform and depends on the shape and size of the particles, which may have masked any changes from the addition of the particles.

"This technology can allow us to study the microstructure of rubber and rubber-like materials under dynamic conditions and can result in the development of fuel-efficient rubber tires or gloves that do not deteriorate. Moreover, this technology can also enable the dynamic X-ray CT imaging of living organs that repeatedly deform, such as the heart, and can even pave the way for the development of artificial organs," says Dr. Matsubara, highlighting the importance of this study.

Overall, this breakthrough technology has the potential to advance the understanding of the microstructure of viscoelastic materials, likely opening the doors for developing novel materials with improved properties.

More information: Masami Matsubara et al, In-situ measurement of dynamic micro X-ray CT and dynamic mechanical analysis for rubber materials, Mechanical Systems and Signal Processing (2023). DOI: 10.1016/j.ymssp.2023.110875