This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Invention reduces cost of manufacturing quick-charging devices

In the course of the transition to e-mobility, range and charging times are becoming increasingly important for more and more people. That's why possibilities for faster charging are of ever-greater interest. Quick charging and charging large batteries require a lot of power. However, manufacturing costs for these high-powered devices remain very high today.

Researchers at the Heilbronn University of Applied Sciences have now developed a process with which quick-charging devices that are designed for high power can be manufactured automatically, and therefore more cost-effectively and in larger quantities. Especially well-suited for this is the process developed by Prof. Dr.-Ing. Michael Kokes, the 3-phase direct resonant charging system, for all fast chargers with very high power, such as the ones required for charging trucks or buses.

Ever-higher power is also required for quick-charge stations for trucks since these vehicles should charge quickly and the charging device must deliver a lot of power in a short time. Previously, these charging stations with power ratings of more than 100 KW were manufactured with line-side transformers or a power converter with a DC link and converter. The costs for the winding materials and capacitors required make manufacturing very expensive, however.

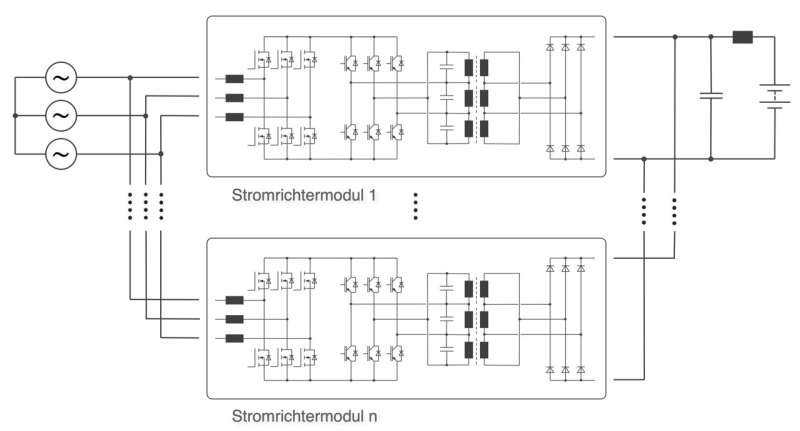

The switching concept developed by Prof. Kokes works with a converter circuit without a line-side transformer and a procedure for generating a potential-isolated DC voltage, which requires almost no capacitors. This makes manufacturing of charging devices in the range up to several 100 KW much cheaper.

The switching concept also provides for a modular design. On the one hand, this means that these charging devices can be manufactured automatically. On the other hand, their modular structure offers a great variety of possible combinations. The individual modules can be used to address a wide range of services and models. Due to switching operations of the resonant converter for potential isolation in the de-energized phases of the DC link, there are no switching losses here. The output voltage is regulated by the line-side converter. Frequency multiplications in the input and output circuits significantly reduce the filtering effort, which in turn significantly reduces costs.

This procedure is especially suitable for quick-charging stations for large vehicles such as trucks and buses. But even automobile charging stations that have to provide a lot of power quickly could be manufactured more cost-effectively with this process.