This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

proofread

A high efficiency LED based on copper–iodide clusters

A team led by Prof. Yao Hongbin from the University of Science and Technology of China (USTC) developed a high efficiency, high brightness warm white light-emitting diode (LED) based on copper-iodide cluster hybrids. Their work is published in Nature Photonics.

Solution-processed LED are considered to be the technology for realizing the next generation of large-area solid-state lighting due to their simple manufacturing process and high operability. At present, solution-processed LED devices based on lead-halide perovskites, organic semiconductor materials, and colloidal core-shell quantum dots (QDs) have achieved high electroluminescence performance.

However, materials containing heavy metals such as lead-halide perovskites and CdSe QDs cause serious environmental issues, while LED devices based on organic light-emitting molecules, InP QDs and ZnSe QDs have high production costs due to their complex synthesis. Therefore, developing solution-processed LED based on low-cost, low-toxicity, easily scalable and highly efficient emitters is the key challenge for future solid-state lighting.

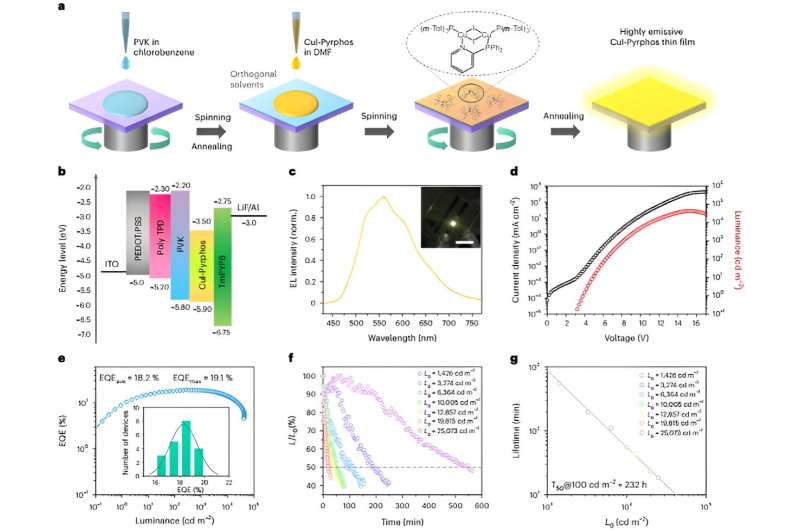

To tackle this challenge, the team first designed and prepared a copper-iodine-based hybrid cluster with a broad photoluminescence spectrum.

By introducing nitrogen-phosphine chelating ligands and phosphine-containing solubilizing ligands, the team obtained copper-iodide hybrid clusters with both high luminescence efficiency and high solubility, which show a high solubility of more than 200 mg/mL and good structural stability in N, N-dimethylformamide (DMF), the cross-solvent used in LED production.

The luminescent thin films fabricated by spin-coating in DMF exhibit a low surface roughness of 0.22 nm and a high photoluminescence quantum yield of more than 70%, which can be used as a luminescent layer to make low-cost warm-white LED devices through an orthogonal solvent route.

The resulting LED devices achieve a maximum external quantum efficiency of 19.1%, a brightness of more than 40,000 cd m-2, and an operational lifetime of more than 232 h (T50@100 cd m-2). Meanwhile, thanks to the good solubility and processability of the clusters, the team constructed a large-area solution-processed LED device with a working area of 36 cm2 through blade-coating, which exhibited warm white light emission with brightness close to 60,000 cd m-2.

In addition, by modifying different electron-donating groups on the nitrogen heterocycles of the nitrogen-phosphine chelating ligands, the team developed a series of solution-processed color-tunable LED devices.

This work realized LED devices with high efficiency and high brightness based on copper-iodide hybrid clusters. The structural expandability and spectral tunability of the copper-iodide hybrid clusters make them promising for fabricating low-cost high-performance LED panels and solid-state lighting.

More information: Jing-Jing Wang et al, High efficiency warm-white light-emitting diodes based on copper–iodide clusters, Nature Photonics (2023). DOI: 10.1038/s41566-023-01340-8