This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Researchers develop next-generation cooling material to increase summer cooling efficiency without electricity

Dr. Jin Gu, Kang and his team at the Nanophotonics Research Center at the Korea Institute of Science and Technology (KIST) have developed a colorful radiation-cooling liquid crystal material that can cool without external power while simultaneously emitting color. The work is published in the Chemical Engineering Journal.

Radiative cooling is a powerless cooling technology that releases infrared radiation as heat through the atmospheric window to reduce temperatures. It is attracting attention as a next-generation eco-friendly cooling technology that can supplement power-hungry air conditioners.

Radiative cooling materials for daytime use are colored white to reduce sunlight absorption. This provides excellent cooling performance but has the disadvantage that it cannot be used in buildings or vehicles that require aesthetics because it is difficult to implement multiple colors.

Therefore, the development of colored radiative cooling materials that meet cooling and aesthetics at the same time has recently attracted attention.

Previously known colored radiative cooling materials use light absorption to produce color, resulting in low temperature reduction. Alternative colored materials in the form of photonic crystals that use light reflection had excellent cooling performance but were limited in realizing distinct colors.

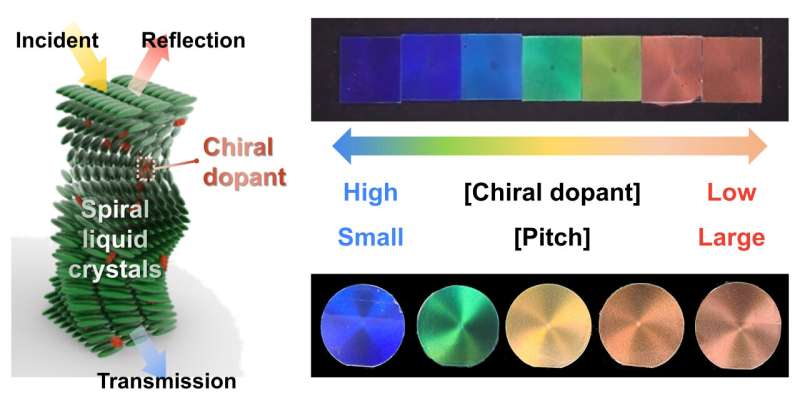

The team solved this problem by fabricating bent spiral liquid crystal photonic crystals. The commercial liquid crystal (LC242) used in this study is not only a material that reduces its temperature through radiation cooling, but also forms colored photonic crystals through its periodic structure when aligned into a spiral using an inducer.

The researchers used a spin coating process to bend these colored photonic crystals, resulting in vivid colors unlike conventional photonic crystals, which have different colors depending on the angle.

-

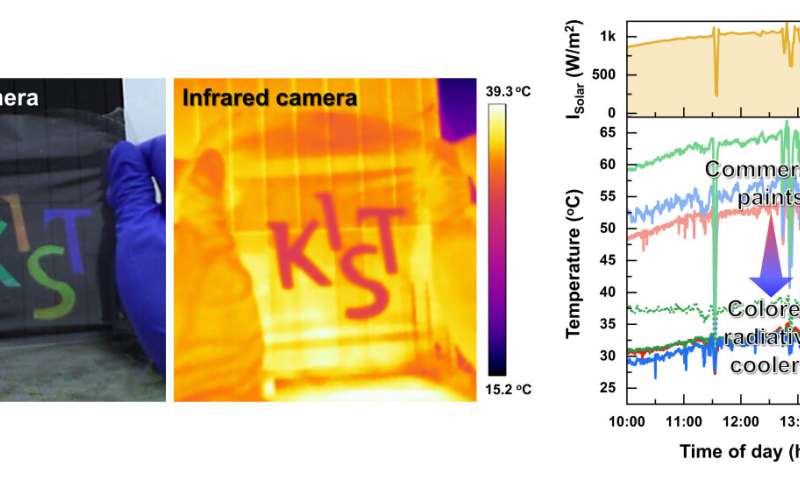

The multi-colored "KIST" letters made from the developed material were photographed with an optical camera and an infrared camera. The temperature of the letters is lower than the surrounding area. (Right) Measurement of the midday temperature change between the colored cooling material and commercial paint. Up to 30.8°C lower temperature was achieved compared to commercial paint. Credit: Korea Institute of Science and Technology -

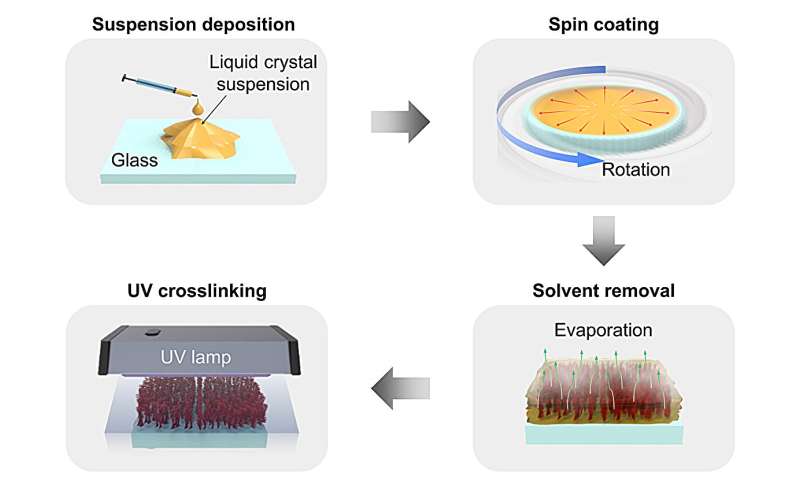

LC 242 liquid crystals and chiral dopants dispersed in an organic solvent are dripped onto a substrate and then applied thinly and widely using spin coating. After evaporation of the solvent, spiral liquid crystal photonic crystals are fabricated by UV curing. Credit: Korea Institute of Science and Technology -

Postdoctoral researcher Minjeong Kim (left) and principal investigator Jin Gu Kang (right) show the colorful radiative cooling material they created in the process lab. Credit: Korea Institute of Science and Technology -

A research team prepares to measure radiative cooling performance in the outdoor experimental space on the roof of the research building. Credit: Korea Institute of Science and Technology

By combining the fabricated colored radiation-cooling liquid crystal material with an upper transparent film and a lower metallic thin film, the team was able to achieve a temperature of about 30.8°C lower than the same colored commercial paint and about 3.1°C lower than ambient air in the middle of the day, the researchers said.

The material could be used to reduce air conditioning consumption on the exterior of buildings and vehicles where aesthetics is a consideration, as well as to provide power-free cooling for outdoor leisure items and military tents.

"The colored radiation-cooling liquid crystal material developed in this study can be quickly fabricated through a low-cost and simple spin coating process," said Dr. Jin Gu Kang, a professor at KIST.

"If the large-scale commercialization of this technology is successful, it will be used for cooling a wide range of fields such as electronics and mobility in the future."

More information: Sangwok Bae et al, Efficient full-color daytime radiative cooling with diffuse-reflection-dominant cholesteric liquid crystals, Chemical Engineering Journal (2024). DOI: 10.1016/j.cej.2024.149245