This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Scientists combine nanotech and deep learning to build ultra-small e-nose system for real-time gas identification

A new ultra-small electronic nose (e-nose) that operates on ultralow power opens up possibilities for applications in various fields, such as air quality monitoring, health diagnostics, food safety, and environmental protection.

Professor Heungjoo Shin in the Department of Mechanical Engineering and Professor Jae Joon Kim in the Department of Electrical Engineering at UNIST have successfully implemented an e-nose capable of accurately measuring both the type and concentration of gases by integrating nanotechnology and deep learning.

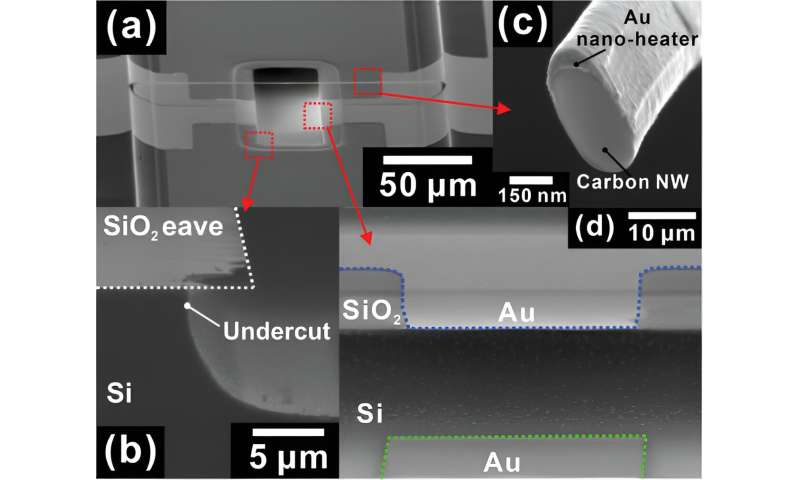

The newly developed e-nose uses a nano-sized heater-based semiconductor gas sensor. Unlike conventional sensors that consume significant power due to high operating temperatures, this sensor operates with less than 200 microwatts, making it ideal for mobile and IoT devices. Furthermore, it boasts high productivity as it leverages semiconductor manufacturing processes.

The high power consumption associated with existing electronic noses has been mitigated through the miniaturization of sensors, complemented by the introduction of duty cycling technology. This technology reduces power consumption by an additional 90% by periodically supplying and cutting off power to the heater.

The nanoheater can reach temperatures of 250°C and cool down to room temperature within one-hundred-thousandth of a second, enabling effective gas measurement even within short duty cycles.

-

Scanning electron microscopy (SEM) images of the suspended nanoheater and built-in shadow mask structure. Credit: Ulsan National Institute of Science and Technology -

Overview of the ultralow-power single-sensor-based e-nose system powered by duty cycling and deep learning for real-time gas identification. Credit: Ulsan National Institute of Science and Technology -

Real-time prediction of gas type and concentration for five gases [air, (a) SO2, (b) CO, (c) H2, (d) NO2] using dual-response signals (time window = 30 s, duty cycle = 10%, duty frequency = 1 Hz). Credit: Ulsan National Institute of Science and Technology

The research team has enhanced the existing e-nose design, which traditionally required multiple sensors, to operate with a single sensor.

Gas desorption from the surface of semiconductors occurs more slowly than the operational speed of the nanoheaters. Consequently, during duty cycling, gas reactions continue even during brief cooling periods of the heater. This allows different signals to be collected both during operation and interruptions of the heater.

By analyzing these dual signals in real time using a convolutional neural network (CNN), the system can accurately identify various gas types and concentrations.

Professor Shin stated, "The limitations of existing electronic noses can be addressed with a single sensor," adding, "This technology can be readily applied to mobile and IoT devices that necessitate miniaturization."

Professor Kim elaborated, "The ability to create a micro-gas measuring device that operates on low power opens avenues for diverse applications, including real-time wireless monitoring systems."

The findings related to the nanometer-based gas sensor were published in September 2022, and the current e-nose technology was published in June 2024 in ACS Sensors.

More information: Taejung Kim et al, Ultralow-Power Single-Sensor-Based E-Nose System Powered by Duty Cycling and Deep Learning for Real-Time Gas Identification, ACS Sensors (2024). DOI: 10.1021/acssensors.4c00471