January 19, 2018 report

A small chemical reactor made via 3-D printing allows for making drugs on-demand

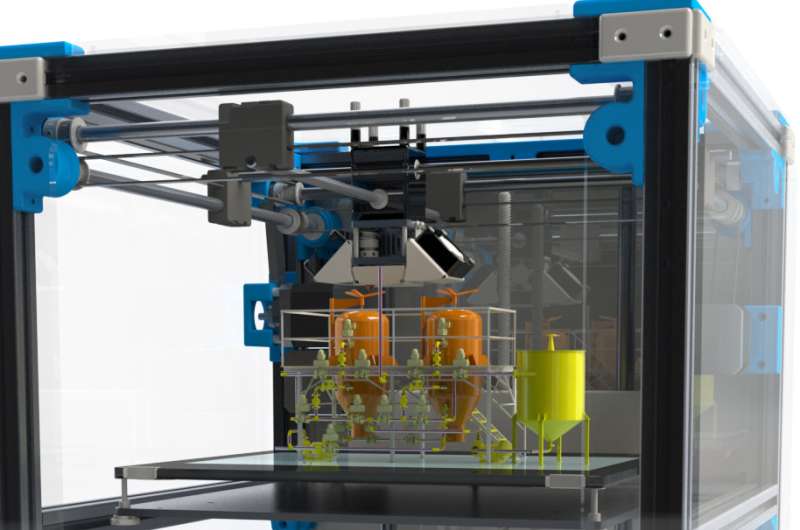

A team of researchers at the University of Glasgow has developed a system based on 3-D printing reactor modules for creating pharmaceuticals on demand. In their paper published in the journal Science, the group describes how the concept works and offers an overview of using their system to create an actual drug. Christian Hornung with CSIRO Manufacturing in Australia offers a Perspective piece on the work done by the team in the same journal issue and outlines possible uses for such a system.

Virtually all commercial drugs are manufactured at large facilities run by giant pharmaceutical companies. This system allows for the manufacture of the millions of doses of drugs taken by patients around the globe, but as the researchers note, it does have some drawbacks. One is the huge expense involved in creating the machines necessary to create the drugs and then retooling them when necessary. Another is the difficulty in justifying the use of such a facility to create a small number of unique drug doses for just a few people who might need them. To address these issues the researchers in Scotland set themselves the task of designing and building a system that would allow people to replicate the processes on a lab table.

The system the team developed involves software, precursors, a 3-D printer and an instruction manual. Software is used to design a reactor which is a series of connected water-bottle sized containers. The reactor is printed by the 3-D printer and then the manual is used by a non-professional to add precursors to the reactor to create the desired drug.

In practice, the software is used to create a blueprint that tells the printer what sort of reactor to make, which means determining the number of containers needed and the ways they are to be connected together. Each reactor requires the design of a single blueprint and instructions on how it is to be used to create one particular drug. Blueprint design would be done by qualified chemists, while in contrast, producing the product would take no more skill, the researchers note, than that possessed by a child.

To prove their idea, the researchers designed a blueprint for the muscle relaxing drug baclofen, printed the reactor for it and then used it to create some samples. Such a system, the team acknowledges, might face some hurdles in acceptance due to the possibility of it being used to create illicit drugs.

More information: Philip J. Kitson et al. Digitization of multistep organic synthesis in reactionware for on-demand pharmaceuticals, Science (2018). DOI: 10.1126/science.aao3466

Abstract

Chemical manufacturing is often done at large facilities that require a sizable capital investment and then produce key compounds for a finite period. We present an approach to the manufacturing of fine chemicals and pharmaceuticals in a self-contained plastic reactionware device. The device was designed and constructed by using a chemical to computer-automated design (ChemCAD) approach that enables the translation of traditional bench-scale synthesis into a platform-independent digital code. This in turn guides production of a three-dimensional printed device that encloses the entire synthetic route internally via simple operations. We demonstrate the approach for the γ-aminobutyric acid receptor agonist, (±)-baclofen, establishing a concept that paves the way for the local manufacture of drugs outside of specialist facilities.

© 2018 Tech Xplore