July 13, 2019 weblog

Motor, other components, in wheels may shape future of car industry

A Tel Aviv-based startup has emerged from stealth and they are spelling out their concept for motors in wheels for engines in electric cars. Tech-watching headlines are calling it a reinvention of wheels but it is essentially a reinvention of the car.

Don't say it never entered anyone's head before this. Try year 1900. The Economist reminded readers that Ferdinand Porsche at the Paris World Fair had a car driven by a pair of electric motors incorporated into the front wheels.

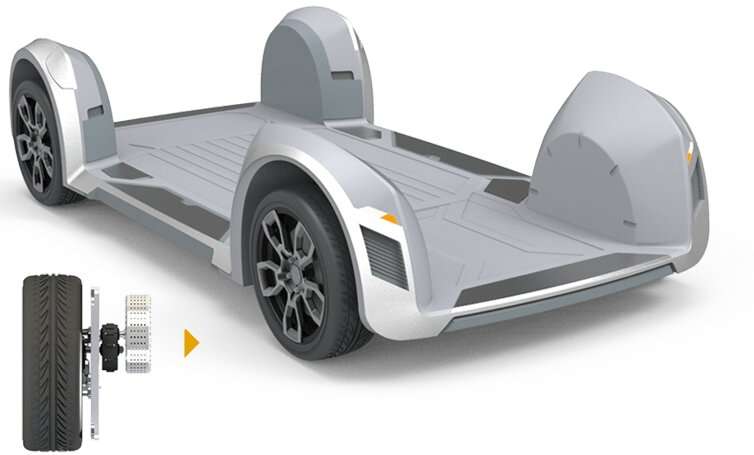

In 2019, the Ree company is taking this to another level. Roadshow: "Ree's idea to put all the drive components inside the wheel isn't necessarily a new idea, but it's going further by including not only the motor inside the wheel but the steering, suspension, drivetrain, sensing, brakes, thermal systems and electronic components as well."

A video shows the motor-in-wheels prototype. Take care not to blink or you miss half the video, which shows a skateboard type of object.

New Atlas said this was the kind of platform that could be used for anything: a delivery van, high-performance off-road vehicle.

Roadshow similarly remarked that "you could conceivably whack any body you like on top of it, depending on your need." The vehicle architecture, significantly simplified, had drive and suspension systems inside its wheels, along with a flat floor made up of a structural battery pack.

Long and short, motor, steering, suspension, drivetrain, sensors, brakes, thermal systems and electronics were in the wheels.

Tami Hood in Hydrogen Fuel News noted in what ways this concept would impact future designs:

The drive components being contained inside the wheels "would eliminate the bulky drive unit that's sitting between the front or rear wheels, providing the benefit of having a totally flat floor for more passenger and cargo space in a given application."

The company CEO, Daniel Barel, had an interview with Interesting Engineering where he relayed his views on their concept vis a vis existing industry concepts. He said the "entire automotive industry is changing, but the vehicle is still being built on 100-year-old concepts."

Fabienne Lang in Interesting Engineering :

"REE's universal platform will be able to replace the multiple ones that OEMs (original equipment manufacturers) are creating and using—and save the industry billions of dollars. Typically, the validation and creation of one platform costs manufacturers $20 billion, so with simply one platform being used in the future, costs will drastically drop." In addition, "safety, performance, and efficiency will be improved. Sounds like a no-brainer."

Roadshow's Kyle Hyatt pointed to some interesting advantages about their idea: (1) the advantage of having a completely flat floor for more passenger and cargo space in a given application and (2) individual motors in each wheel were "opening the door for really advanced torque vectoring, which would—in theory, at least—improve both safety and handling."

The company is referred to as a startup but, actually, as Loz Blain reported in New Atlas, for the last six or so years, CEO Barel and the team were "in stealth mode working on a completely new approach to the entire automotive segment."

Barel talked to Blain about the team's four "pillars" underlying the architecture: modularity, tiny footprint, energy efficiency (to max the range possible from a battery charge); and "lightweighting."

Vehicle designers might even think about a decision to rearrange the seats or even use new body shapes, said electrive.com.

Could we be looking at a complete disruption of the auto industry? Barel did not ignore the economic driver in talking to Blain. "The single biggest expenditure for an OEM auto manufacturer is the platform, developing and validating it. It costs billions, it takes years, and each OEM has between two and six platforms at any given moment, and two or three in development. We went in and said 'what if you might need only one? That might be worth something.'"

What's next? Barel said he expected the first Ree-architecture vehicles to hit the market around 2023, according to New Atlas.

The company's history can be traced to SoftWheel, which carries some news items about their new concept.

According to a news release in September last year, SoftWheel's focus was described as developing "cutting edge systems for the automotive industry, enabling the fusion of the drivetrain, suspension, e-motor, steering, and brakes into the vehicle's wheel. Its innovative technology enables significant reduction in space, weight, and energy consumption of vehicle platforms for EV, hybrid, and autonomous vehicles."

Reports, meanwhile, said the company was talking with a number of OEMs. As for press reactions, the response to the Ree tech was basically sounds-interesting-let's-wait-and-see.

New Atlas: We look forward to learning more about REE's potentially disruptive auto architecture as it develops and moves toward the market. At this stage we've only seen a very short video of one of the prototypes...We have requested more information, diagrams and photos from REE and hope to bring them to you soon."

More information: ree.auto/

www.prnewswire.com/news-releases/wheel-reinvented—ree-emerges-from-stealth-to-power-the-future-of-mobility-300882679.html

© 2019 Science X Network