A blast of gas for better solar cells

Treating silicon with carbon dioxide gas in plasma processing brings simplicity and control to a key step for making solar cells.

A simple process for depositing silicon oxide onto silicon wafers could be a great step forward for making silicon-based solar cells. Researchers at KAUST have used a method called plasma processing in a chamber filled with carbon dioxide gas.

The semiconducting element silicon is the material of choice for around 90 percent of solar cell production. When the silicon is doped with selected impurities, the energy from sunlight can kick electrons into generating a flow of electric current.

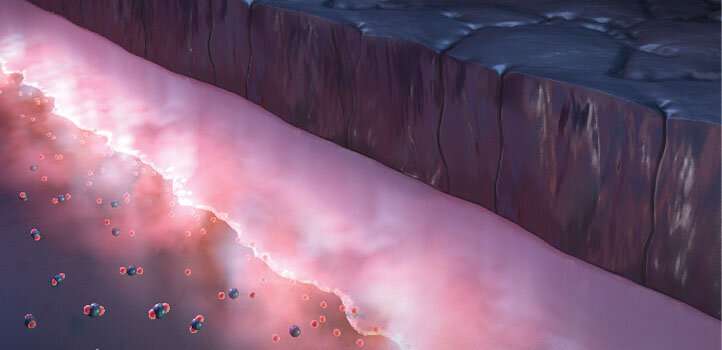

A technical challenge arises, however, at the exposed surface of the silicon, described by Areej Alzahrani, a KAUST Ph.D. student, as the problem of "dangling bonds." She explains that the reduced availability of silicon atoms to bond together at the surface leaves scope for electrons ejected by light energy to recombine with the positively charged "holes" that the departing electrons leave behind.

This problem can be resolved by generating a layer of silicon oxide at the surface regions used to form electrical contacts in a chemical process called passivation. Several methods can achieve this, but they all come with difficulties and limitations. They also introduce an additional and costly fabrication step. "The problems with existing methods challenged us to find a more simple and practical process," says Alzahrani.

The solution involves exposing the silicon to carbon dioxide in plasma—a low temperature ionized gas. This allows controlled deposition of silicon oxide, followed by the overlaying of another silicon layer, as required for the architecture of a solar cell. Achieving both these steps in the same chamber offers a significant reduction in production costs. "This straightforward and simple process could be of great use to the solar cell industry," Alzahrani concludes.

She points out that the team was surprised by the control that the method achieves over the deposition of an ultrathin silicon oxide layer with the required microstructure. It also generates oxide films that are more stable at high temperatures, overcoming another problem with existing methods. Tests revealed the procedure permits high voltages and low electrical resistance, as required for efficient performance.

Now the team has demonstrated the basic technique, it plans to move to develop its commercial potential. "A first step will be to integrate this process into a complete and working solar cell, while also exploring improved light-capturing designs," says research group leader, Stefaan De Wolf.

More information: Areej Alzahrani et al. In Situ Plasma‐Grown Silicon‐Oxide for Polysilicon Passivating Contacts, Advanced Materials Interfaces (2020). DOI: 10.1002/admi.202000589