Binder-free sandwich structure film as a high-capacity cathode for aluminum-sulfur battery

Aluminum-sulfur (Al-S) battery system possesses the theoretical energy density as high as 1340 W h kg-1. Such high energy density and cheap raw materials make Al-S battery a promising alternative-energy storage device. However, sulfur is a conversion-type cathode material and will generate a series of polysulfides and sulfides during the charge/discharge process. Polysulfides can easily lose electrical contact with the host and diffuse to the electrolyte or Al anode, leading to the shuttle effect, which is the main reason for low capacity, low efficiency, and rapid capacity decay. As a result, novel electrode materials and structural design strategies are desired to overcome these obstacles.

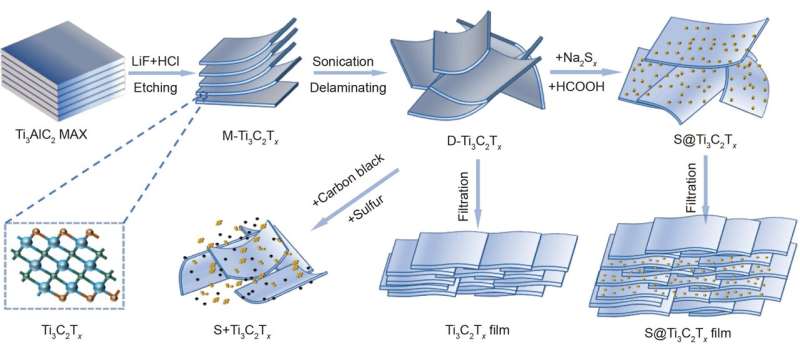

Researchers from Shanghai Jiao Tong University have designed a new binder-free S@Ti3C2TX sandwich structure film with uniform sulfur dispersion as a high-capacity cathode that offers several important advantages.

This new structure consists of three parts. The upper and lower surfaces of the film were covered with a very thin pure Ti3C2Tx film, and the main part in the middle was composed of a S@Ti3C2Tx composite. The composite was formed by the in-situ controllable chemical deposition of nano sulfur in the Ti3C2Tx solution, which ensured the dispersion of sulfur.

"The main attraction of this material is that the protective layer was directly added on the surface of the S@Ti3C2Tx composite to block the polysulfides, different from the previously reported strategy of using graphene coating on the separator to mitigate the shuttle effect," said Xiao Zheng.

Generally, the polymer binder is an inactive component that will increase the electrode mass and reduce the energy density of the battery, easily undergoing side reactions with ionic liquids. The binder-free film only needed to be filtered and dried, and no additional binders, conductive agents, and toxic organic solvents were needed in the preparation process. Ti3C2Tx had the function of not only a binder but also a conductive agent.

In addition, Xiao Zheng and Zhilong Wang used density functional theory (DFT) calculations to predict the adsorption of polysulfides on Ti3C2Tx and used common graphene materials as a reference to highlight the advantages of Ti3C2Tx. Subsequently, they purposed the reasonable discharge-charge reaction mechanism of the Al-S batteries.

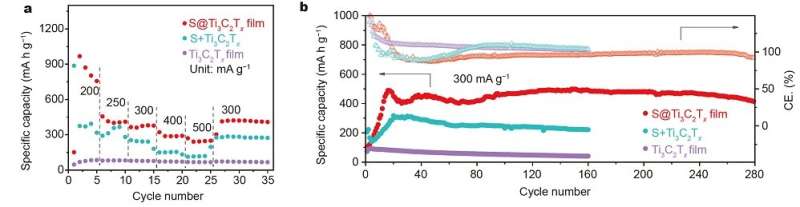

As a result, their electrode showed excellent cycling performance. The initial reversible capacity of 489 mA h g-1 at 300 mA g-1 after the initial short-term activation, and the capacity remained at 415 mA h g-1 after 280 stable cycles, with an average Coulombic efficiency of ~95%.

The research was published in Science China Materials.

More information: Xiao Zheng et al, Binder-free S@Ti3C2Tx sandwich structure film as a high-capacity cathode for a stable aluminum-sulfur battery, Science China Materials (2022). DOI: 10.1007/s40843-021-1913-4